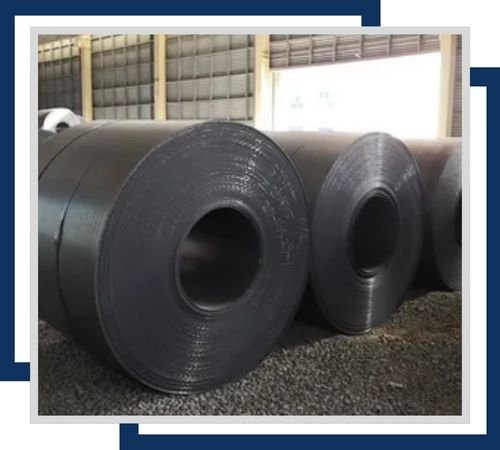

Based in Chennai, India, Vinit Stainless is one of the most respected producers and distributors of premium stainless steel goods. We provide an extensive selection of stainless solutions, including the highly sought-after SMO 254 Coils, with a strong emphasis on quality, performance, and dependability. These coils are well-known for their exceptional strength, durability, and resistance to corrosion, making them perfect for use in harsh industrial settings such as chemical processing and the maritime industry. Our products are manufactured to the highest industry standards and sourced from reputable vendors, guaranteeing consistent performance and customer satisfaction in a range of demanding applications.

The high-alloy austenitic stainless steel used to make SMO 254 coils has a low carbon content, about 20% chromium, 18% nickel, 6% molybdenum, and 0.2% nitrogen. Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking caused by chloride is provided by this special composition. The material has remarkable ductility and weldability, as well as a yield strength of about 300 MPa and a tensile strength of up to 650 MPa. As a reliable solution for harsh and corrosive operating environments, its mechanical robustness and thermal stability enable it to function consistently at high temperatures.

| Elements | Carbon | Chromium | Manganese | Molybdenum | Nickel | Nitrogen | Phosphorus | Silicon | Sulphur |

|---|---|---|---|---|---|---|---|---|---|

| SMO 254 UNS S31254 | 0.02 max | 19.5-20.5 | 1.0 max | 6.0-6.5 | 17.5-18.5 | 0.18-0.22 | 0.03 max | 0.8 max | 0.01 max |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Cb+Ta |

| SMO 254 Coils | 0.07 | 1.0 max | 1.0 max | 0.03 | 3.0 – 5.0 | Bal | 3.0 – 5.0 | 15.0 – 17.5 | 5 X C / 0.45 |

Contact us to get a quick quote for your requirement.

F44 SMO 254 coils offer exceptional corrosion resistance and strength, ideal for chemical processing, marine, and aerospace applications. Their high performance ensures reliability in harsh environments and extreme conditions.

SMO 254 (S31254) strips and coils provide superior corrosion resistance and strength, suitable for harsh environments. Ideal for chemical, marine, and aerospace applications, they ensure durability under extreme conditions

ASTM A240 SMO 254 (S31254) coils are high-grade stainless steel, offering excellent corrosion resistance and strength. They are ideal for use in harsh chemical, marine, and high-temperature environments.

SMO 254 (UNS S31254) coils provide superior corrosion resistance and strength, making them ideal for chemical, marine, and high-temperature applications. Their durability ensures reliability in extreme and aggressive environments.

SMO 254 coils are high-performance stainless steel, known for outstanding corrosion resistance and strength. Ideal for harsh environments, they are used in chemical processing, marine, and high-temperature applications.

SMO 254 stainless steel coils offer excellent corrosion resistance and high strength. Ideal for demanding environments, they are used in chemical, marine, and high-temperature applications, ensuring durability and reliability.

Vinit Stainless will provide high-performance SMO 254 Coils with consistency backed by extensive test ranges such as hardness testing, spectro analysis, PMI, and flaring tests. The company also does micro and macro tests, pitting resistance tests, and IGC tests for superior quality coils. In addition to our intense testing protocols, we ensure comprehensive documentation by including commercial invoices and packaging lists showing net and gross weights, box numbers, and labels. A legalized or attested Certificate of Origin along with Third-Party Inspection Certificates ensures the superiority of SMO 254 Coils as well as unbeatable customer satisfaction.

SMO 254 Coils are perfect for the chemical processing, marine, and aerospace industries because they are widely used in extremely corrosive and hot environments. Their strong oxidizing agents and exceptional resistance to chloride-rich environments guarantee their dependable use in pulp and paper mills, heat exchangers, desalination plants, and pressure vessels. They are also preferred in pollution control devices, pharmaceutical manufacturing systems, and offshore oil and gas platforms. The alloy is the preferred material for critical applications requiring long service life and corrosion resistance due to its exceptional strength, weldability, and durability under mechanical and thermal stress.

©2024 Vinit Stainless All Rights Reserved.