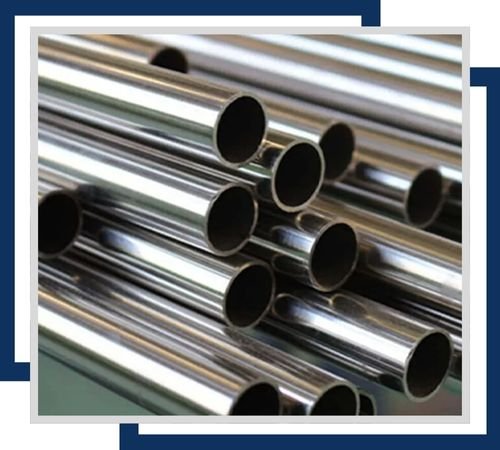

Known for providing high-performance stainless steel solutions, Vinit Stainless is a well-known manufacturer and supplier of stainless steel 440C pipes in Chennai, India. Our SS 440C pipes are made for uses that call for exceptional strength, hardness, and resistance to wear. Our pipes are made to exacting international standards for quality and longevity using cutting-edge manufacturing processes and high-quality raw materials. Vinit Stainless is dedicated to offering accurate, corrosion-resistant piping solutions to the oil and gas, automotive, aerospace, and tooling industries. We guarantee dependable delivery and affordable prices for all stainless steel products, with an emphasis on client satisfaction.

High carbon (about 1.0–1.2%), chromium (16–18%), and trace amounts of silicon, manganese, and molybdenum make up stainless steel 440C pipes. Following heat treatment, this martensitic stainless steel provides exceptional hardness and wear resistance. It offers outstanding hardness up to 58 HRC, a high tensile strength of about 760 MPa, and a yield strength of about 450 MPa. Its mechanical qualities make it perfect for applications needing durability, edge retention, and resistance to wear under mechanical stress, even though its corrosion resistance isn’t as strong as that of austenitic grades.

| Thickness | 0.5mm-100mm | ||||||

| Outer diameter | 10mm, 25.4mm, 38.1mm, 50.8mm, 100mm, 250mm, 300mm, 350mm, etc | ||||||

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc | ||||||

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc | ||||||

| Finish | Hot rolled (HR), Cold rolled Tube (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) | ||||||

| Form | Round tube Square tube Rectangular tube etc. | ||||||

Carbon | 0.95 to 1.20 | % | Manganese (Maximum) | 1.00 | % |

Phosphorus (Maximum) | 0.040 | % | Sulfur (Maximum) | 0.030 | % |

Silicon (Maximum) | 1.00 | % | Chromium | 16.00 to 18.00 | % |

Molybdenum (Maximum) | 0.75 | % | Iron | Balance |

| Temp°C | Tensile (UTS)N/mm² | 0.2% YieldN/mm² | Elongation(50.8mm) % | HardnessHRc | Reductionof Area |

| 20 | 1965 | 1896 | 2 | 57 | 10 |

Contact us to get a quick quote for your requirement.

We offers the very best quality in Stainless Steel 440C Pipes, with strenuous testing involved in tensile, hardness, and corrosion tests. All these products adhere to International Standards, verified by ISO as well as other reputed Agencies. Third Party inspection and reports on material traceability ensure absolute reliability, fitting a wide cross-section of needs within industries without equal.

Stainless Steel 440C square pipes offer high hardness, strength, and excellent wear resistance. They are used in demanding applications such as hydraulic cylinders, machinery, and automotive components due to their durability.

SS 440C seamless pipes provide exceptional hardness and corrosion resistance. Ideal for high-stress environments, they are used in industries like aerospace and automotive for components requiring high strength and durability.

Stainless Steel 440C ERW pipes offer high hardness and corrosion resistance. Suitable for high-stress applications, they are used in automotive, aerospace, and industrial applications requiring durability and strength.

SS 440C LSAW pipes are fabricated using longitudinal dip arc welding, providing superior strength and corrosion resistance. Ideal for heavy duty applications in oil and gas and other industries and construction.

Stainless Steel 440C round pipes are durable, corrosion-resistant, and used in demanding applications. They offer high strength and hardness, making them suitable for various industrial and structural uses.

Stainless Steel 440C welded pipes are high-strength, corrosion-resistant pipes used in harsh environments. They offer excellent hardness and wear resistance, suitable for applications requiring durability and structural integrity.

For high-strength, high-wear applications in a variety of industries, stainless steel 440C pipes are perfect. These pipes, which are valued for their hardness and abrasion resistance, are frequently found in precision instruments, automotive parts, aerospace components, and valve systems. Because of their exceptional edge retention, they are used in cutting tools and surgical instruments in the food and medical industries. Additionally, SS 440C pipes are utilised in moulds, bearing races, and hydraulic systems where high mechanical strength and resistance to wear are crucial. They work very well in dry or mildly corrosive applications, but they are not appropriate for extremely corrosive settings.

©2024 Vinit Stainless All Rights Reserved.