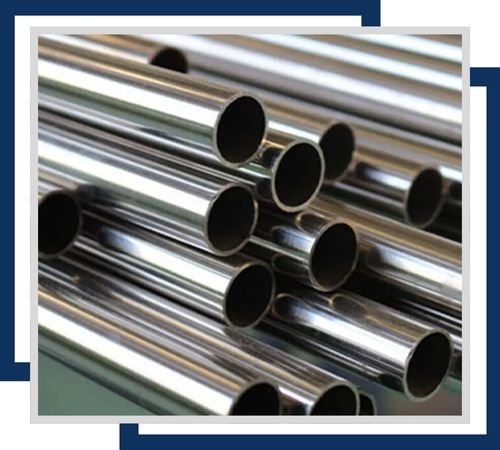

Vinit Stainless, one of the best manufacturers and suppliers in Chennai, India, deals exclusively in high-grade Stainless Steel 904L Pipes. These pipes are carefully designed to ensure outstanding resistance to corrosion in extremely aggressive atmospheres, hence very suitable for businesses that handle robust acids and chlorides. Our SS 904L pipes find extensive application due to their higher resistance to pitting, crevice corrosion, and stress corrosion cracking, thus ensuring long-term strength and reliability in demanding fluid handling systems.

904L Stainless Steel is an austenitic high-alloy stainless steel. Its general composition consists of 23-28% Nickel, 19-23% Chromium, 4-5% Molybdenum, and 1-2% Copper with an extremely low carbon content in order to inhibit intergranular corrosion. Mechanically, it has good tensile strength, generally between 490 MPa, and a yield strength of approximately 220 MPa. Its high ductility makes fabrication easy, while its strong mechanical properties provide resilience under operating stress.

| Standard | ASTM A312 |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Thickness | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1510 °C (2750 °F) | Psi – 75,000 , MPa – 485 | Psi – 40,000 , MPa – 275 | 20 % |

Contact us to get a quick quote for your requirement.

The SS 904L seamless pipe is a high-alloy austenitic stainless steel known for its exceptional corrosion resistance, making it ideal for harsh environments in chemical and marine industries.

The SS 904L welded pipe offers excellent corrosion resistance and strength, suitable for chemical processing, oil and gas, and marine applications, ensuring durability and reliability in harsh environments.

The SS 904L ERW pipe combines excellent corrosion resistance and high strength, making it ideal for chemical, petrochemical, and marine applications, offering durability and reliability in demanding environments.

The SS 904L EFW pipe provides superior corrosion resistance and high strength, ideal for chemical and petrochemical industries, ensuring durability and reliability in extreme environments and high-pressure applications.

The SS 904L rectangular pipe offers excellent corrosion resistance and high strength, ideal for structural and architectural applications in chemical, marine, and industrial environments, ensuring durability and longevity.

The SS 904L square pipe features high corrosion resistance and strength, making it suitable for structural, architectural, and industrial applications, particularly in harsh chemical and marine environments.

Stainless Steel 904L Pipes find widespread application in chemical plants that deal with sulfuric acid, phosphoric acid, and acetic acid. They are also crucial for drug manufacturing, pulp and paper sectors, and seawater cooling systems. Other significant applications involve oil and gas exploration drilling, pollution control devices, and desulfurization units. Their excellent resistance to different types of corrosion renders them essential for carrying corrosive media, providing safety and reducing maintenance needs in aggressive industrial environments.

©2024 Vinit Stainless All Rights Reserved.