Home > Electrodes > AWS Class E320LR-16 Electrodes

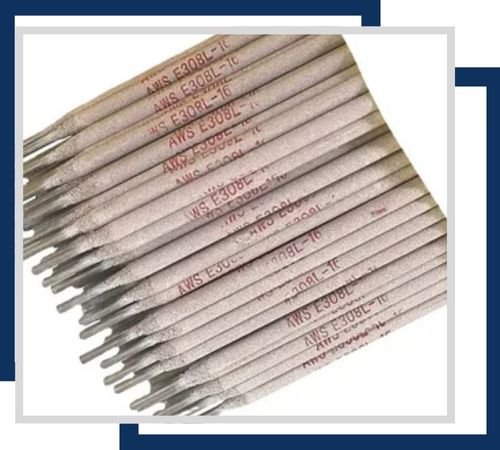

AWS E320LR-16 electrodes are intended for use in welding high-alloy stainless steels that need a defense against severe chemical attack, particularly in sulfuric acid rich environments. Manufactured by Vinit Stainless, these low-residual electrodes provide superior performance in severe applications where weld purity and corrosion resistance are mandatory. The “LR” indicates lower residual elements, assisting in reducing the danger of weld contamination and cracking. These electrodes are preferred when fabricating equipment for use in the chemical, pharmaceutical, and pulp & paper processes, where the best possible weld integrity is a must.

E320LR-16 contains 19-21% Chromium, 32-36% Nickel, 2.5-3.5% Molybdenum, and traces of carbon, silicon, and residual elements. These electrodes impart welds with tensile strength of about 690 MPa and better corrosion resistance in acid environments. The minimum residual content minimizes the possibility of intergranular corrosion and improves ductility and impact strength. The completely austenitic microstructure offers superior weldability with AC and DC power. E320LR-16 electrodes work well in all positions and create smooth, clean weld beads with simple slag removal, particularly critical for high-purity process environments.

| Classification | AWS A5.4, E320LR-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E320LR-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Nb + Ta | Mn | Si | P | S | Cu |

| 0.03 | 19.0-21.0 | 32.0-36.0 | 2.0-3.0 | 8 X C, min to 0.40 max | 1.50-2.50 | 0.30 | 0.02 | 0.015 | 3.0-4.0 |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent corrosion resistance and are suitable for welding stainless steel structures. They come in various diameters, such as 2.5 mm, 3.2 mm, and 4.0 mm. The light coating facilitates smooth arc stability and minimal spatter.

Providing superior corrosion resistance, heavy-coated electrodes are ideal for high-stress applications. They are available in diameters of 3.2 mm, 4.0 mm, and 5.0 mm. The heavy coating enhances the weld’s integrity and improves its resistance to oxidation.

With excellent corrosion resistance, these electrodes are designed for shielded arc welding of stainless steel. They are typically available in 2.5 mm, 3.2 mm, and 4.0 mm. The shielded arc provides enhanced protection against contamination during welding.

E320LR-16 electrodes are utilized for joining high-alloy austenitic stainless steels like Alloy 20 and other nickel-chromium-molybdenum steels. They are essential in environments exposed to sulfuric acid, nitric acid, and other corrosive agents. Industries like chemical processing, food manufacturing, and pharmaceuticals use these electrodes to construct pressure vessels, reactors, piping, and pumps. Their low-carbon formulation prevents carbide precipitation, making them suitable for high-temperature service and improving weld longevity. E320LR-16 is also applicable in welding castings and components in acid plants, paper mills, and waste treatment plants needing corrosion-proof performance and structural integrity.

©2024 Vinit Stainless All Rights Reserved.