Home > Electrodes > AWS Class E330-16 Electrodes

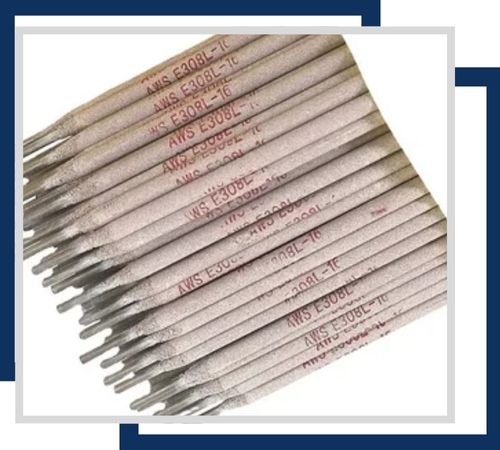

Vinit Stainless supplies AWS Class E310-16 Electrodes, which are produced to satisfy high-temperature welding conditions for heat-resistant stainless steels. Headquartered in Chennai, India, the company provides these electrodes to industries that engage in thermal processing, power generation, and furnace production. E310-16 Electrodes are renowned for their superior oxidation resistance and capacity to sustain heat up to 1100°C. Vinit Stainless focuses on accuracy in formulation as well as coating quality, which leads to a steady arc, smooth bead finish, and effortless slag removal. Decades of experience and a preoccupation with engineering-grade performance have made Vinit Stainless a trusted supplier of heat-resisting welding consumables.

AWS E310-16 Electrodes contain a nominal composition of 25–28% chromium, 19–22% nickel, ≤0.20% carbon, and small amounts of manganese, silicon, and phosphorus. Fully austenitic, this electrode provides outstanding resistance to heat and oxidation. Typical mechanical properties are tensile strength of 600 MPa, yield strength of 300 MPa, and elongation of 30–35%. It is stable structurally and does not scale up to 1100°C. The electrode forms stable welds with excellent crack resistance and is best suited for welding dissimilar metals and joining steels subjected to high thermal stress or to fluctuating high rates of temperature change.

| Classification | AWS A5.4, E330-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E330-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.18-0.25 | 14.0-17.0 | 33.0-37.0 | 0.75 | 1.0-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent corrosion resistance for welding stainless steel. They are typically available in diameters ranging from 2.5 mm to 5.0 mm and lengths of 300 mm to 450 mm. The light coating ensures smooth arc stability and ease of operation.

Providing superior corrosion resistance, heavy-coated electrodes are designed for demanding environments. Sizes generally range from 3.2 mm to 5.0 mm in diameter and lengths of 350 mm to 450 mm. The heavy coating enhances the arc stability and weld quality in challenging applications.

These electrodes feature excellent corrosion resistance and are ideal for shielded arc welding. They come in diameters from 2.5 mm to 4.0 mm and lengths of 300 mm to 450 mm. The shielding provides effective protection against contamination during the welding process.

AWS Class E310-16 Electrodes are employed for welding heat-resistant stainless steels and dissimilar metals where the strength and resistance to oxidation at elevated temperatures are of prime importance. Typical applications are in the areas of furnace components, heat exchanger components, incinerators, and equipment in petrochemicals and power plants. They are also employed for carbon steel welding to austenitic stainless steels and for overlay welding in surfaces experiencing thermal cycling. E310-16 can be used for high-temperature ducts, kilns, and combustion chambers. Its thermal fatigue and oxidation resistance in aggressive environments makes it the best for repair and maintenance applications in conditions beyond normal stainless steel capabilities.

©2024 Vinit Stainless All Rights Reserved.