Home > Electrodes > AWS Class E347-16 Electrodes

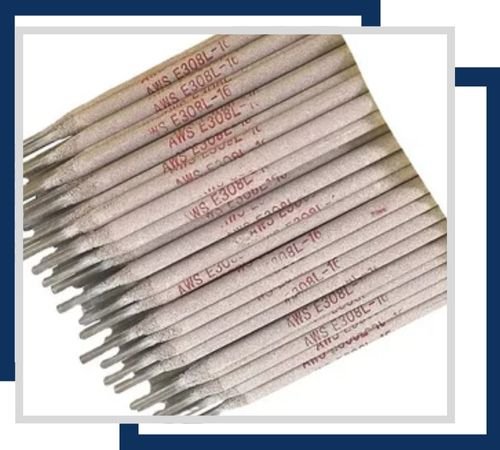

Vinit Stainless is a leading producer and supplier of AWS Class E347-16 Electrodes in Chennai, India, providing expert solutions for welding stabilized stainless steels. They are columbium (niobium) stabilized, giving them superior resistance to intergranular corrosion in cycling heat and cool applications. Vinit Stainless features each E347-16 electrode for having the best arc control, handling, and uniform mechanical performance. They excel at welding 321 and 347 stainless steels in pressure vessels, heat exchangers, and chemical equipment. Their strength and metallurgical stability, E347-16 electrodes are generally accepted in all high-temperature industrial processes.

E347-16 Electrodes consist of around 18–20% chromium, 9–11% nickel, ≤0.04% carbon, and niobium (columbium) as stabilizer. It prevents the precipitation of carbides during welding and enhances high-temperature strength. The weld metal is completely austenitic with superior oxidation resistance. Characteristics commonly seen are tensile strength of 580 MPa, yield strength of about 400 MPa, and elongation of 30%. The electrodes possess resistance to intergranular corrosion even after multiple thermal cycling, which renders them suitable for use in high-pressure applications at high temperatures and in conditions where thermal fatigue is an issue.

| Classification | AWS A5.4, E347-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E347-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Nb+Ta | Mn | Si | P | S | Mo | Cu |

| 0.08 | 18.0-21.0 | 9.0-11.0 | 8xC-1.0 | 0.5-2.5 | 1.0 | 0.04 | 0.03 | 0.75 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer exceptional corrosion resistance, particularly against intergranular corrosion. Typically available in diameters of 1/16″ to 1/8″ (1.6 mm to 3.2 mm), they provide a lighter coating, facilitating easier welding with smooth, clean welds and minimal spatter.

Known for high corrosion resistance, especially in harsh environments, these electrodes come in diameters of 1/8″ to 5/32″ (3.2 mm to 4.0 mm). The heavy coating enhances arc stability and provides a thicker slag layer, offering better protection and ease of removal for cleaner welds.

These electrodes deliver superior corrosion resistance and are ideal for high-temperature applications. Typically available in diameters of 3/32″ to 1/8″ (2.4 mm to 3.2 mm), they are designed for shielded arc welding, ensuring stable arcs and good weld integrity in challenging conditions.

AWS Class E347-16 Electrodes are most commonly used for welding stabilized stainless steels like AISI 321 and 347 in applications including repeated heating between 427–816°C. Typical uses include pressure vessels, furnace parts, chemical tanks, and piping systems in power plants and refineries. Their stabilized chemistry resists intergranular corrosion due to carbide precipitation, so they are the best choice for welding in corrosive and heat-conscious environments. E347-16 is also applied in the food processing industry, drug plants, and in aerospace components where oxidation resistance and long-term structural stability are needed. These electrodes retain weld strength and corrosion resistance during extended thermal exposure.

©2024 Vinit Stainless All Rights Reserved.