Vinit Stainless is a leading producer and supplier of SS 410S Pipes in Chennai, India. Our emphasis is on quality and customer satisfaction, and we focus on providing corrosion-resistant stainless steel solutions for industrial applications. Our SS 410S Pipes are engineered to operate under high temperature and mildly corrosive conditions. With decades of experience in the stainless steel sector, we provide high quality pipes renowned for strength, durability, and affordability. For automobile, petrochemical, or construction industries, Vinit Stainless provides guaranteed supply and accurate engineering in each SS 410S pipe we provide.

SS 410S is a low-carbon, non-hardenable stainless steel alloy. It generally has 11.5–13.5% chromium content, with low carbon (<0.08%) to enhance weldability and formability. Its mechanical properties consist of tensile strength 415 MPa (min), yield strength 205 MPa (min), and elongation 20%. It has a Brinell hardness of around 170 HB. The alloy possesses good oxidation and corrosion resistance in mildly corrosive atmospheres, ideal for high-heat applications. SS 410S is ductile even after extended exposure to high temperatures.

Specifications : ASTM A731, A268 / ASME SA731, SA268

Dimensions : ASTM, ASME and API

Size : 1/2″ NB to 24″ NB

Type : Seamless, Welded, EFW, ERW, Fabricated

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

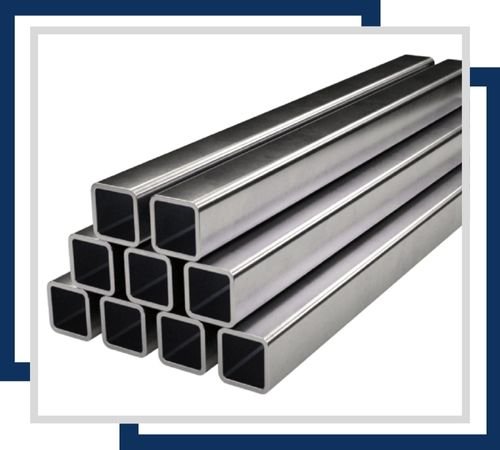

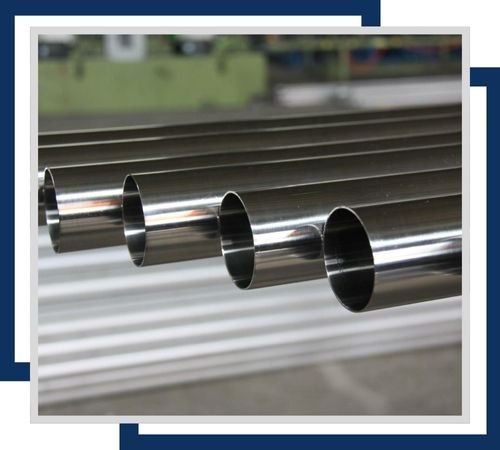

Form : Round Pipes, Square Pipes, Rectangular Pipes, Oval Pipes, Hydraulic Pipe, etc.

End : Plain End, Treaded, Beveled End

Length : Single Random, Double Random & Cut Length. (Custom Sizes Available as per customers requirement)

| Element | Content (%) |

|---|---|

| Iron, Fe | 85 |

| Chromium, Cr | 12.5 |

| Manganese, Mn | 1.0 |

| Silicon, Si | 1.0 |

| Carbon, C | 0.080 |

| Phosphorous, P | 0.040 |

| Sulfur, S | 0.030 |

| Properties | Metric | Imperial |

|---|---|---|

| Density | 7.80 g/cm3 | 0.282 lb/in³ |

| Melting point | 1532°C | 2790°F |

Contact us to get a quick quote for your requirement.

410S Square Pipes offer moderate corrosion resistance and are suitable for structural applications. Common sizes range from 20×20 mm to 150×150 mm. They are used in architectural and industrial projects requiring aesthetics and strength.

410S Seamless Pipes provide good corrosion resistance with smooth, uniform surfaces. Sizes typically range from 1/8 inch to 12 inches in diameter. These pipes are ideal for high-pressure applications and offer high strength and durability.

410S ERW (Electric Resistance Welded) Pipes are moderately resistant to corrosion and suitable for various structural uses. They are available in sizes from 1 inch to 24 inches in diameter and are commonly used in pipelines and construction.

410S LSAW (Longitudinal Submerged Arc Welded) Pipes feature good corrosion resistance and are used in high-pressure environments. They come in sizes from 12 inches to 100 inches in diameter, ideal for large-scale industrial applications.

410S Round Pipes offer moderate corrosion resistance and are available in diameters ranging from 1/8 inch to 12 inches. They are commonly used in structural and mechanical applications requiring strength and durability.

410S Welded Pipes provide moderate corrosion resistance and are used in various industrial applications. Sizes generally range from 1/2 inch to 24 inches in diameter. They are preferred for their cost-effectiveness and versatility in different environments.

SS 410S Pipes find extensive use in the automotive sector for exhaust applications because of their heat resistance and long life. They also find application in petrochemical processing, heat exchangers, and furnace parts. Their low carbon composition guarantees less scaling and better weldability, thus making them suitable for structural and mechanical uses. These tubes find application in oil refineries and thermal processing plants. SS 410S is also employed in pollution control equipment and process pipes, where high strength and resistance to oxidation are essential. Its low cost and ease of fabrication further contribute to its industrial desirability.

©2024 Vinit Stainless All Rights Reserved.