Home > Electrodes > AWS Class E385-16 Electrodes

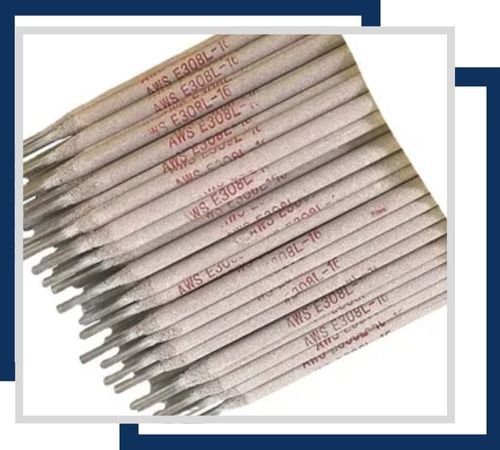

We are a well-known distributor of AWS Class E385-16 Electrodes in Chennai, India, providing cutting-edge welding solutions to highly corrosion-resistant stainless steels. Such electrodes are fabricated for welding ASTM AISI 904L stainless steel and other similar high-alloy austenitic grades. E385-16 electrodes are recognized for uniform quality and performance, for which Vinit Stainless takes every precaution to produce each electrode under stringent quality controls, rendering smooth arc stability and low spatter. Designed with corrosion resistance in severe environments, E385-16 electrodes are applied extensively in chemical processing, pulp and paper, and marine sectors. Vinit Stainless continues to be the go-to supplier of high-performance and reliable welding consumables.

AWS E385-16 Electrodes consist of about 20.5% chromium, 25–28% nickel, 4–5% molybdenum, ≤0.035% carbon, and minor amounts of copper, manganese, and silicon. This high alloy content offers enhanced resistance to severe acids and chloride-induced corrosion. Welds produced by these electrodes contain very high toughness and strength, with tensile strength of about 570 MPa, yield strength of about 380 MPa, and elongation between 35–40%. Deposited metal has excellent corrosion resistance and ductility even after being exposed to harsh environments, which makes E385-16 suitable to weld 904L and other super austenitic stainless steels.

| Classification | AWS A5.4, E385-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E385-16 Coated Electrodes Application & uses |

|

| Grade | C | Cr | Cu | Fe | Mn | Mo | Ni | N | P | Si | S |

| SS E385-16 | 0.015 max | 20.5 max | 1.70 max | Bal | 2.10 max | 4.60 max | 25.2 max | 0.04-0.08 | 0.018 max | 0.45 max | 0.009 max |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent corrosion resistance, particularly for welding high-strength stainless steel structures. They come in various sizes, including 3.2 mm (1/8 in) and 4.0 mm (5/32 in) diameters, providing strong welds with smooth, light coatings.

Featuring superior corrosion resistance, these electrodes are ideal for heavy-duty welding tasks. They are available in 3.2 mm (1/8 in) and 4.0 mm (5/32 in) diameters, designed for high-strength applications with thicker coatings for enhanced performance.

These electrodes are used in shielded arc welding processes for stainless steel, providing robust corrosion resistance. They are offered in sizes like 3.2 mm (1/8 in) and 4.0 mm (5/32 in) diameters, ensuring strong, reliable welds with excellent shielding properties.

AWS Class E385-16 Electrodes are designed to be used mainly for welding 904L and other high-alloy steels that are austenitic stainless and are subject to severe chemical and acidic environments. Typical applications include industries such as chemical processing, pulp and paper, pharmaceutical, and manufacturing of marine equipment. The electrodes are suitable for tanks, vessels, piping systems, and pumps with sulfuric acid, phosphoric acid, and seawater. Their outstanding corrosion resistance also makes them ideal for food processing and desalination plants, too. E385-16 electrodes are utilized in cladding service over carbon steel where better corrosion protection is needed, ensuring long service life and resistance to local corrosion.

©2024 Vinit Stainless All Rights Reserved.