Home > Electrodes > AWS Class ER316/316L SAW and FLUX

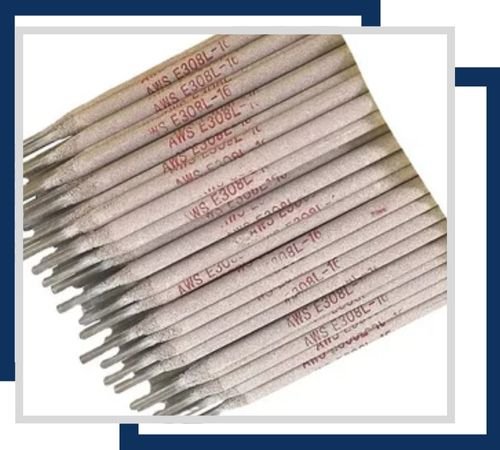

Vinit Stainless, a top-notch manufacturer and supplier located in Chennai, India, specializes in high-quality AWS Class ER316/316L Submerged Arc Welding (SAW) wire and flux. These products are specifically crafted for welding molybdenum-bearing austenitic stainless steels, ensuring exceptional corrosion resistance and top-tier weld quality, even in tough conditions. With a commitment to international quality standards, Vinit Stainless guarantees consistent chemistry, smooth feeding, and impressive deposition efficiency. Their SAW wires and compatible fluxes are perfect for automated welding in pressure vessels, chemical tanks, heat exchangers, and other critical components in demanding industrial environments.

Vinit Stainless’s AWS Class ER316/316L SAW wire features a composition of 18–20% chromium, 11–14% nickel, and 2–3% molybdenum, with a low carbon content in the 316L grade to reduce carbide precipitation and intergranular corrosion. When paired with the right flux, it delivers a weld deposit with a tensile strength of about 550–620 MPa, outstanding ductility, and improved resistance to pitting and crevice corrosion. This wire and flux combination ensures easy slag removal, a smooth bead profile, and excellent mechanical properties, making it ideal for multi-pass, high-deposition welds on critical stainless steel components.

| Classification | AWS A5.9, ER316/316L |

| Form | Welding Fluxes and Wires |

| Type Of Welding | Submerged Arc Welding |

| Thickness available | Upto 4 mm |

| AWS ER316/316L SAW & Flux Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.03 | 23.0-25.0 | 12.0-14.0 | 0.75 | 1.0-2.5 | 0.30-0.65 | 0.03 | 0.03 | 0.75 |

| Tensile Strength, kpsi: | 86* |

| Yield Strength, kpsi: | 58* |

| Elongation %: | 40* |

Contact us to get a quick quote for your requirement.

Alloy ER316/316L SAW and Flux are used in submerged arc welding for stainless steel, offering excellent corrosion resistance, strength, and a clean, slag-free weld for applications in harsh environments.

AWS A5.9 ER316/316L SAW and Flux Welding Wire is designed for submerged arc welding of stainless steel, providing strong, corrosion-resistant welds with a clean, slag-free finish for demanding applications.

AWS Class ER316/316L Submerged Arc Welding Flux provides excellent arc stability, ensuring high-quality, corrosion-resistant welds with minimal spatter and a clean, slag-free finish for stainless steel applications.

We ensure comprehensive documentation for our AWS Class ER316/316L SAW and FLUX products, providing transparency and reliability. Our documents include a commercial invoice, packaging list, fumigation certificate, heat treatment chart and a quality assurance plan. The package also includes a NABL-approved lab test report, confirming compliance with stringent standards. Our commitment to quality is further validated through various test certificates, such as MTC as per EN 10204/3.1b, PMI Test Certificate, 100% radiography test report and a Third-Party Inspection Certificate. These measures collectively guarantee 100% client satisfaction and confidence in the integrity of our products.

Vinit Stainless’s ER316/316L SAW wire and flux find extensive use across various industries, including chemical processing, food and beverage, marine, pharmaceuticals, oil and gas, and power generation. These filler materials are perfect for welding 316 and 316L stainless steels in storage tanks, pipelines, pressure vessels, heat exchangers, and structural components that face chloride-rich or acidic environments. The low carbon content of 316L guarantees excellent resistance to intergranular corrosion without the need for post-weld heat treatment. Designed for high-efficiency submerged arc welding, these products are a reliable choice for demanding applications.

©2024 Vinit Stainless All Rights Reserved.