Home > Electrodes > AWS Class E410-16 Electrodes

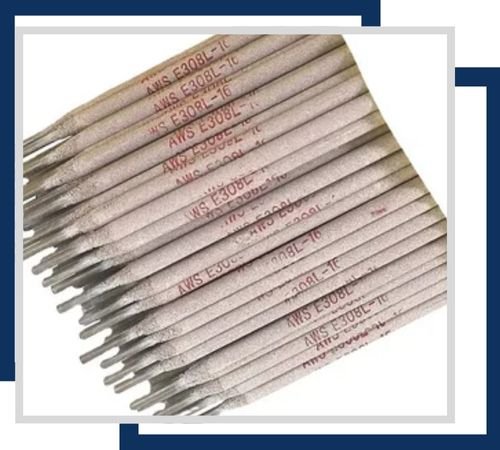

Vinit Stainless is a top distributor of AWS Class E410-16 Electrodes in Chennai, India, providing excellent welding solutions for stainless steel fabrication. The electrodes are specifically designed to weld 12% chromium stainless steels like AISI 410 and comparable ferritic/martensitic grades. Vinit Stainless makes sure that every batch of electrodes is stringently checked for quality and complies with international standards of welding. Reputed for stable arc performance, minimum spatter, and good slag removal, these electrodes find extensive use in fabrication, refinery, and repair applications. Clients trust Vinit Stainless for performance-led welding products that provide precision, reliability, and mechanical strength in demanding applications.

AWS Class E410-16 Electrodes consist of about 11.5–13.5% chromium and 0.12% carbon with small additions of manganese, silicon, phosphorus, and sulfur. It creates a martensitic microstructure appropriate for air-hardening steels. Mechanical properties have tensile strength of 630 MPa, yield strength of about 480 MPa, and elongation of 20–25%. Hardness is up to 250 HB. These electrodes offer tough, crack-resistant welds with moderate heat resistance and corrosion, good for welding steels that need post-weld heat treatment. The structure provides wear resistance and structural integrity under challenging environments.

| Classification | AWS A5.4, E410-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E410-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.12 | 11.0-13.5 | 0.7 | 0.75 | 1.0 | 0.90 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer moderate corrosion resistance and are designed for welding stainless steel to itself or to carbon steel. They typically come in sizes like 1/8″ (3.2mm), 5/32″ (4mm), and 3/16″ (4.8mm), providing flexibility for various applications.

Featuring excellent corrosion resistance, these electrodes are used for welding stainless steel components, especially in demanding environments. Common sizes include 1/8″ (3.2mm), 5/32″ (4mm), and 3/16″ (4.8mm). Their heavy coating ensures better arc stability and coverage.

These electrodes provide robust corrosion resistance and are suited for shielding gas protection applications. They are available in sizes such as 1/8″ (3.2mm), 5/32″ (4mm), and 3/16″ (4.8mm), offering reliable performance in various welding conditions.

AWS Class E410-16 Electrodes find extensive application in welding martensitic stainless steels such as AISI 410 and 420 in wear-resistant and moderately corrosive applications. Typical uses are turbine blades, valves, pump components, and heat-resistant parts. They are ideal for welding in the petrochemical complex, refineries, and structural repair work. They also work well on overlay and build-up work on carbon steel components for corrosion protection. Postweld heat treatment is usually used to restore hardness and avoid cracking, making them useful for precision industrial welding operations.

©2024 Vinit Stainless All Rights Reserved.