Home > Electrodes > AWS Class E410NiMo-16 Electrodes

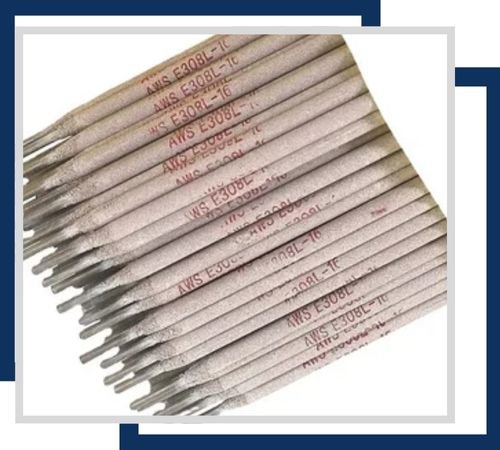

Vinit Stainless provides high–quality AWS Class E410NiMo-16 Electrodes to its industrial customers in Chennai, India. These are specialized electrodes designed for welding martensitic stainless steels needing extra strength and corrosion resistance, particularly in chloride or marine environments. Containing nickel and molybdenum, E410NiMo-16 electrodes make welds that are stronger and more resistant to pitting and stress corrosion cracking. Vinit Stainless has a reputation for reliable supply chain, technical advisory, and quality assurance. Their electrodes are embraced in industries operating high-pressure, chemical processing, and heat applications requiring strong and wear-resistant welds.

E410NiMo-16 electrodes have around 11.5–13.5% chromium, 4–5% nickel, 0.5–1% molybdenum, ≤0.12% carbon, and trace amounts of manganese and silicon. The alloy provides improvement in corrosion resistance, particularly in chlorinated and acidic environments. The deposit weld obtains tensile strength of approximately 630 MPa, yield strength of about 480 MPa, and elongation of 20-25%, while hardness is up to 250 HB. These mechanical properties impart strength, ductility, and pitting corrosion resistance. Welding using E410NiMo 16 is extremely long lasting and possesses excellent toughness and corrosion resistance, especially under varying temperature and pressure conditions.

| Classification | AWS A5.4, E410NiMo-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E410NiMo-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.06 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 1.0 | 0.90 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent corrosion resistance and are designed for applications requiring moderate to high tensile strength. They come in diameters ranging from 2.5 mm to 4.0 mm and lengths typically between 300 mm and 350 mm, making them ideal for thin-walled sections and precision welding.

Known for superior corrosion resistance, these electrodes are suitable for welding thicker sections and high-strength joints. Available in diameters from 3.2 mm to 5.0 mm and lengths of 300 mm to 400 mm, they are optimized for more demanding welding tasks requiring robust performance.

These electrodes have exceptional corrosion resistance and are ideal for shielded arc welding applications. They come in various diameters, including 2.5 mm, 3.2 mm, and 4.0 mm, with lengths of 300 mm to 400 mm, providing flexibility for various welding positions and joint configurations.

AWS Class E410NiMo-16 Electrodes are applied for welding martensitic stainless steels in aggressive environments like offshore platforms, desalination plants, and chemical processing equipment. Their corrosion resistance in chloride-containing conditions is also applied in pressure vessels, pumps, shafts, and impellers in marine and oil & gas industries. AWS Class E410NiMo-16 Electrodes are also used in overlay applications to strengthen corrosion resistance on mild steel parts. Their strength retention and resistance to cracking even at elevated temperatures make them perfect for thermal and mechanical cycling in power plants and petrochemical plants.

©2024 Vinit Stainless All Rights Reserved.