Vinit Stainless, a well-known stainless steel tubing producer and supplier in Chennai, India, supplies excellent SS 420 tubing for various industrial uses. SS 420 is a high-carbon martensitic stainless steel that has superior strength, hardness, and wear resistance. The SS 420 tubing is produced with precision and rigorous quality checks to be up to international standards like ASTM A268. SS 420 tubing is well suited to usage where mechanical strength and some corrosion resistance are needed. Vinit Stainless provides robust, dimensionally correct tubing with on-time shipment to industries like engineering, tooling, and automotive manufacturing.

| Specifications | : | ASTM A/ASME SA213/ A249/ A269 |

| Dimensions | : | ASTM, ASME and API |

| SS 310/ 310S Tubes Size | : | 1/8″NB TO 30″NB IN |

| Schedule | : | SCH20, SCH30, SCH40, XS, STD, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Thickness | : | 0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm. |

| Form | : | Round, Rectangular, Square, Hydraulic Etc |

| Type | : | Seamless / Fabricated / ERW / Welded / LSAW Tubes |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treaded |

| AISI 904L | Maximum | Minimum |

|---|---|---|

| Ni | 28.00 | 23.00 |

| C | 0.20 | – |

| Mn | 2.00 | – |

| P | 00.045 | – |

| S | 00.035 | – |

| Si | 1.00 | – |

| Cr | 23.0 | 19.0 |

| Mo | 5.00 | 4.00 |

| N | 00.25 | 00.10 |

| CU | 2.00 | 1.00 |

| Element | Grade 904L |

|---|---|

| Density | 8 |

| Melting Range | 1300 -1390 ℃ |

| Tensile Stress | 490 |

| Yield Stress (0.2%Offset) | 220 |

| Elongation | 35% minimum |

| Hardness (Brinell) | – |

Contact us to get a quick quote for your requirement.

With outstanding corrosion resistance, Stainless Steel 904L Seamless Tubing is ideal for high-pressure applications. Typically available in sizes ranging from 1/8″ to 8″ in diameter and custom lengths, it offers uniform strength and durability without weld seams.

Welded stainless steel tubing provides good corrosion resistance and is often used in less critical applications. Sizes generally range from 1/2″ to 12″ in diameter. Its manufacturing process involves welding a flat-rolled stainless steel sheet into a tube shape.

Stainless steel heat exchanger tubes are highly corrosion-resistant and designed for thermal conductivity. Available in various sizes, typically from 1/2″ to 4″ in diameter and up to 20 feet long. Essential for efficient heat transfer in industrial processes.

Instrumentation stainless steel tubing offers excellent corrosion resistance and is used for precise control systems. Standard sizes range from 1/16″ to 1″ in diameter. It ensures reliable performance in various high-pressure and high-temperature applications.

Boiler tubes of stainless steel are known for their exceptional corrosion and high-temperature resistance. Available in sizes from 1/2″ to 4″ in diameter. Designed for use in power generation and industrial boilers to handle high-pressure steam.

Stainless steel U-tubes provide high corrosion resistance and are used in heat exchangers and condensers. Sizes usually range from 1/2″ to 4″ in diameter. They are fabricated into a U shape to fit specific thermal or fluid flow requirements.

Condenser tubes made of stainless steel are highly corrosion-resistant and used in cooling systems. Commonly available in diameters from 1/2″ to 4″ and lengths up to 20 feet. Essential for efficient heat exchange in cooling applications.

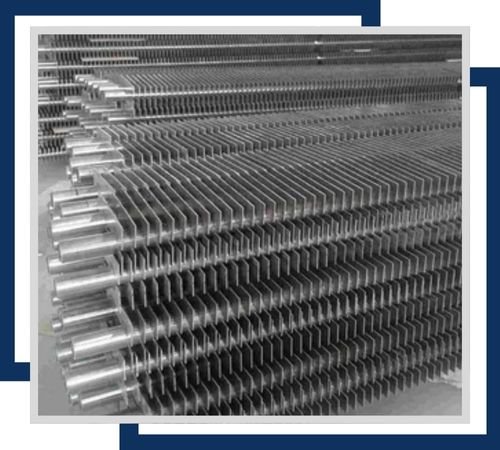

Stainless steel fin tubes offer enhanced heat transfer efficiency and corrosion resistance. Sizes range from 1/2″ to 4″ in diameter with various fin heights and thicknesses. They are used in applications with critical heat exchange efficiency, such as HVAC systems.

SS 420 tubing is commonly applied to applications involving high mechanical strength, hardness, and wear resistance. Common uses are in surgical instruments, cutlery, automobile parts, valves, shafts, and pump rods. It’s applied to machine parts and tooling in the fields of engineering where wear on the surface is an issue. SS 420 tubing is also used in water treatment, mild chemical environments, and steam lines. Its hardenability makes it perfect for precision finished parts. While not ideal for extremely corrosive environments, SS 420 tubing works well in dry or slightly corrosive situations under good surface finishing.

©2024 Vinit Stainless All Rights Reserved.