Based in Chennai, India, Vinit Stainless is a top producer and supplier of stainless steel 304L tubing. Vinit Stainless, known for its dependability and quality, offers tubing solutions that satisfy the exacting requirements of sectors like pharmaceuticals, food and beverage, and chemical processing. After welding, SS 304L tubing, a low-carbon form of 304 stainless steel, exhibits exceptional resistance to corrosion and intergranular attack. Vinit Stainless guarantees that every product satisfies international standards by employing sophisticated manufacturing processes and stringent quality controls. They are a reputable brand in stainless steel tubing solutions because of their dedication to accuracy, prompt delivery, and client satisfaction.

Austenitic stainless steel with a low carbon content (up to 0.03%), stainless steel 304L tubing provides better weldability and a lower chance of carbide precipitation. Because of its 18–20% chromium and 8–12% nickel content, it has exceptional corrosion resistance. With good ductility and elongation, the tubing has a yield strength of about 170 MPa and a tensile strength of about 485 MPa. Because it resists oxidation and retains its mechanical integrity in temperatures ranging from moderate to high, SS 304L can be used in a variety of industries for both structural and fluid-carrying applications.

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| SS 304L | S30400 | 1.4301 | SUS 304 | Z7CN18‐09 | 304S31 | 08Х18Н10 | X5CrNi18-10 |

| SS | 304 |

|---|---|

| Ni | 8 – 11 |

| Fe | Balance |

| Cr | 18 – 20 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.040 max |

| S | 0.030 max |

| N | – |

| Grade | 304 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | 201 |

Contact us to get a quick quote for your requirement.

Stainless Steel 304I Seamless Tubing offers superior strength and corrosion resistance, ideal for high-pressure applications. Available in sizes ranging from 1/8” to 24” in diameter, it is crafted without any welded seams, ensuring durability and leak-proof performance.

Stainless Steel 304I Welded Tubing provides excellent resistance to corrosion and is cost-effective for less demanding applications. Typically available in sizes from 1/8” to 48” in diameter, it features welded seams and is suitable for a wide range of industrial uses.

Stainless Steel 304I Heat Exchanger Tube is designed for optimal thermal transfer and corrosion resistance in various heat exchanger systems. These tubes are available in sizes from 1/4” to 2” in diameter and are perfect for applications requiring efficient heat conduction.

Stainless Steel 304I Instrumentation Tubing is precision-made for high-pressure, high-purity, and corrosive environments. Available in sizes from 1/16” to 2” in diameter, it is ideal for instrumentation and control systems.

Stainless Steel 304I Boiler Tubes are engineered to withstand high temperatures and pressures in boiler applications. Ranging in sizes from 1/2” to 5” in diameter, they offer excellent resistance to oxidation and scaling.

Stainless Steel 304I U-Tubes are bent into a U-shape, perfect for heat exchangers and boiler applications where space efficiency and corrosion resistance are crucial. Sizes typically range from 1/4” to 2” in diameter, providing reliable performance in compact systems.

Stainless Steel 304I Condenser Tube is designed for high-efficiency heat exchange and corrosion resistance in condenser applications. These tubes come in sizes from 1/4” to 2” in diameter and are essential for maintaining system efficiency.

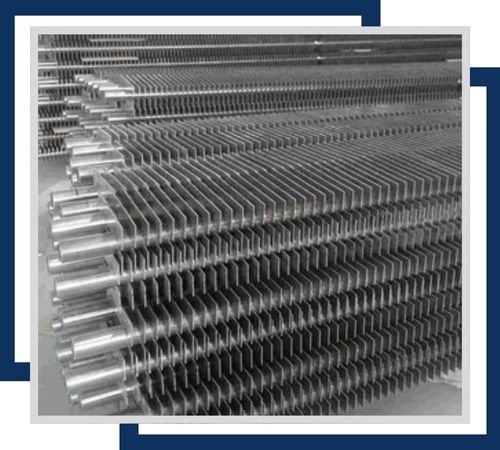

Stainless Steel 304I Fin Tubes feature extended surfaces (fins) to enhance heat transfer and corrosion resistance. Available in various diameters and fin configurations, they are ideal for applications needing increased heat dissipation.

Applications needing weldability, hygienic conditions, and corrosion resistance frequently use stainless steel 304L tubing. It is frequently found in chemical processing lines, dairy and brewing systems, pharmaceutical equipment, and food and beverage processing. Because of its low carbon content, it is particularly well-suited for welded structures where resistance to intergranular corrosion is essential, like pressure vessels, piping systems, and heat exchangers. Additionally, SS 304L tubing is utilised in architectural settings, marine environments, and water treatment. It is perfect for applications needing both mechanical performance and hygienic conditions because of its strength, versatility, and cleanliness.

©2024 Vinit Stainless All Rights Reserved.