Premium stainless steel 347H tubing designed for high-temperature and high-pressure industrial applications is available from Vinit Stainless, a reputable manufacturer and supplier with headquarters in Chennai, India. Advanced production techniques and premium raw materials are used in the fabrication of our SS 347H tubing, which offers exceptional strength, resistance to corrosion, and long-term thermal stability. 347H tubing’s higher carbon content makes it perfect for settings where heat exposure occurs continuously. Vinit Stainless makes certain that all tubing satisfies global standards and supplies goods in unique sizes and finishes to reliably and precisely service industries like chemical processing, heat exchangers, petrochemicals, and power generation.

For enhanced high-temperature strength, stainless steel 347H tubing has a higher carbon content (up to 0.10%), 9–13% nickel, and 17–19% chromium. Niobium (columbium) stabilises it, avoiding carbide precipitation when it is welded and exposed to high temperatures. The tubing has a yield strength of about 205 MPa and a tensile strength of 515–750 MPa. When used continuously up to 870°C, SS 347H retains its structural integrity and resistance to oxidation. Additionally, it has good toughness, weldability, and creep resistance, which makes it a good choice for harsh mechanical and thermal settings.

| Specifications | ASTM A/ASME SA213/A249/A269/A312/A358 |

| Dimensions | ASTM, ASME, and API |

| Size | 1/8″NB TO 30″NB IN |

| 304 Pipes & Tubes Size | 1/2″ NB – 16″ NB |

| ERW 304 Pipes & Tubes | 1/2″ NB – 24″ NB |

| EFW 304 Pipes & Tubes | 6″ NB – 100″ NB |

| Thickness | 0.3mm – 50 mm |

| Specialized in | Large Diameter Size |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Form | Round, Square, Rectangular, Hydraulic, Oval, U Shape, Pan Cake Coils, Coiled Etc |

| Length | Single Random, Double Random & Required Length. |

| End | Plain End, Beveled End, Treaded |

| Stainless Steel | Nickel | Magnesium | Silicon | sulfur | Carbon | Chromium | Phosphorus | Molybdenum | Nitrogen | |

| 347H | Minimum | 9 | 00.04 | 17 | 3 | |||||

| Maximum | 13 | 2 | 1 | 00.030 | 00.10 | 19 | 00.045 | 4 | ||

| SS Grade | Tensile Strength | Yield Strength | Elongation | Hardness | |

| Rockwell B | Brinell | ||||

| SS 347H | 515 | 205 | 40 | 92 | 201 |

Contact us to get a quick quote for your requirement.

This tubing comes in various sizes, typically ranging from 1/8″ to 12″ in diameter. It offers high resistance to oxidation and corrosion, particularly in high-temperature environments. Ideal for applications requiring robust strength and durability.

Available in diameters from 1/2″ to 12″, this tubing is welded and offers similar high-temperature strength as seamless options. It is highly resistant to intergranular corrosion and is used in environments exposed to sulfuric and nitric acids.

These tubes are generally available in sizes from 1/4″ to 2″ OD. They are specifically designed for high-efficiency heat transfer and offer excellent resistance to oxidation and sulfidation. Suitable for use in high-temperature heat exchangers.

Instrumentation tubing sizes typically range from 1/16″ to 1″. It is designed for precise and reliable measurements in harsh environments, providing excellent resistance to corrosion and high temperatures.

Available in diameters from 1/2″ to 5″, these tubes are designed to withstand high pressures and temperatures in boilers. They offer strong resistance to oxidation and carburization, making them ideal for high-temperature steam applications.

These tubes are usually sized from 1/2″ to 3″ in diameter and are formed into a U-shape for use in heat exchangers and other applications. They provide high resistance to corrosion and high-temperature deformation.

Condenser tubes come in sizes from 1/2″ to 3″ OD. They are designed for efficient heat transfer and resist corrosion from various coolants and environmental conditions, ensuring longevity in condenser systems.

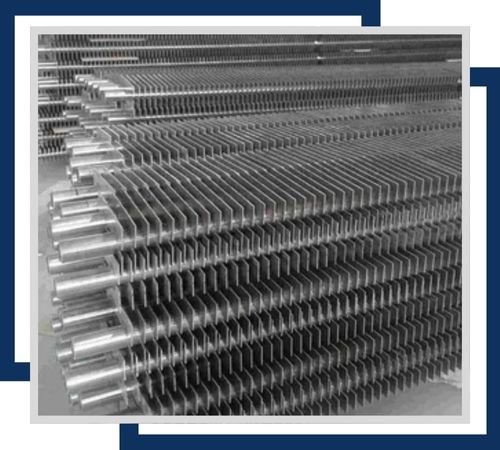

Typically ranging from 1/2″ to 3″ OD, these tubes are fitted with fins to enhance heat transfer efficiency. They offer high resistance to oxidation and corrosion, making them suitable for use in heat exchangers and cooling systems.

When long-term performance is crucial, stainless steel 347H tubing is perfect for use in corrosive, high-temperature settings. It is frequently utilised for heat exchanger tubes, boiler tubes, superheaters, and re-heater systems in power plants, petrochemical facilities, and refineries. In systems subjected to high-pressure steam and frequent thermal cycling, the tubing operates exceptionally well. It is appropriate for structural and process piping in chemical processing and aerospace applications due to its resistance to intergranular corrosion following welding. In applications where elevated temperature strength is a crucial requirement but post-weld heat treatment is impractical, SS 347H tubing is especially valued.

©2024 Vinit Stainless All Rights Reserved.