Vinit Stainless, a quality stainless steel products manufacturer and supplier based in Chennai, India, provides excellent-performance SS 17-7 PH tubing for harsh industrial and aerospace applications. The precipitation-hardened stainless steel grade has the superior corrosion resistance of austenitic stainless steel coupled with the excessive strength and hardness of martensitic types. SS 17-7 PH tubing is reputed for superior fatigue strength, low distortion during heat treatment, and resistance in high-stress situations. Made to international specifications like ASTM A213 and A269, Vinit Stainless exports SS 17-7 PH tubing for severe applications in aerospace, petrochemical, automotive, and mechanical systems.

SS 17-7 PH tubing consists of about 16–18% chromium, 6.5–7.75% nickel, 0.75–1.5% aluminum, and ≤0.09% carbon. Upon precipitation hardening, it has excellent mechanical strength with tensile strength to 1310 MPa and yield strength to 1170 MPa based on heat treatment (such as RH 950 or CH 900). The tubing has excellent fatigue strength, moderate corrosion resistance, and retains good mechanical properties to 600°F (315°C). It is magnetic and low-distortion, hence suitable for precision parts that have to be both formable and of high strength.

| Tensile Strength | 1100 MPa (160,000 psi) minimum |

| Yield Strength | 1035 MPa (150,000 psi) minimum |

| Elongation | 20% minimum |

| Hardness | HRC 40-47 (in Condition TH1050) |

| Element | Min | Max |

|---|---|---|

| Cr | 16 | 18 |

| Ni | 6.5 | 7.75 |

| Al | 0.75 | 1.5 |

| Mn | – | 1 |

| Si | – | 1 |

| C | – | 0.09 |

| P | – | 0.04 |

| S | – | 0.03 |

| Fe | Balance | |

Contact us to get a quick quote for your requirement.

Stainless Steel 17-7PH Seamless Tubing offers high strength and moderate corrosion resistance. Available in sizes ranging from 0.25″ to 2″ OD, it is ideal for aerospace and chemical processing applications. Its seamless construction ensures uniformity and integrity under pressure.

Stainless Steel 17-7PH Welded Tubing provides excellent formability and corrosion resistance. Sizes range from 0.5″ to 4″ OD, suitable for structural and mechanical uses. The welded seams are treated to enhance durability and prevent corrosion

Stainless Steel 17-7PH Heat Exchanger Tubes are designed for high-temperature environments, offering excellent corrosion resistance. Available in sizes from 0.5″ to 3″ OD, these tubes are crucial for efficient heat transfer in industrial processes. They are often used in power generation and petrochemical industries.

Stainless Steel 17-7PH Instrumentation Tubing ensures precision and high corrosion resistance. Typically available in sizes from 0.125″ to 1″ OD, it is perfect for sensitive instrumentation and control systems. Its stability under varying pressures makes it ideal for critical applications.

Stainless Steel 17-7PH Boiler Tubes are built to withstand high pressures and temperatures, with excellent corrosion resistance. Sizes range from 0.5″ to 5″ OD, making them suitable for power plants and industrial boilers. They ensure long-lasting performance under extreme conditions.

Stainless Steel 17-7PH U-Tubes offer great strength and corrosion resistance, ideal for heat exchangers and condensers. Available in sizes from 0.5″ to 2.5″ OD, these U-shaped tubes facilitate efficient thermal transfer. Their design allows for effective use in compact spaces

Stainless Steel 17-7PH Condenser Tubes are corrosion-resistant and highly durable, ideal for condensing heat in various systems. Sizes range from 0.5″ to 3″ OD, used extensively in HVAC and refrigeration industries. These tubes ensure efficient and reliable performance.

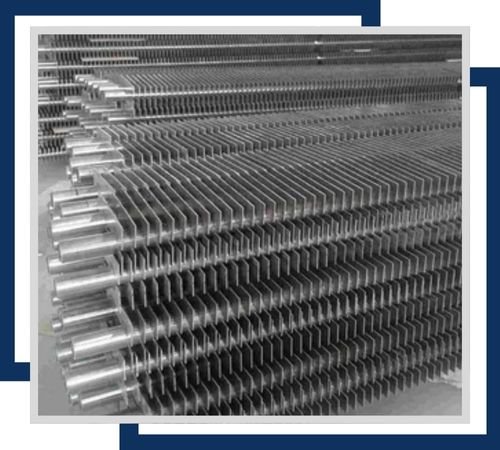

Stainless Steel 17-7PH Fin Tubes enhance heat transfer efficiency while providing excellent corrosion resistance. Available in sizes from 0.5″ to 3″ OD with various fin configurations, they are used in heat exchangers and cooling applications. The fins increase the surface area for better thermal performance.

SS 17-7 PH tubing has extensive applications in aerospace parts, hydraulic actuators, and high-performance springs because of strength and stability. In the automotive industry, it’s utilized in exhaust systems, structural tubing, and performance parts. It is also employed in chemical processing, petrochemical facilities, and nuclear reactors where high stress and consistent mechanical performance are required. The tubing‘s negligible thermal distortion and fatigue strength enable its use for precision instrumentation, bellows, and tubing in dynamic pressure and pressurized conditions. Its particular strength, corrosion resistance, and formability guarantee longevity in the most stressful applications.

©2024 Vinit Stainless All Rights Reserved.