Vinit Stainless is a well-known manufacturer and supplier of Stainless Steel 410S Tubing, having its headquarters in Chennai, India. The company supplies precision-grade tubing for applications in thermal and oxidation-sensitive environments. Stainless Steel 410S Tubing has better weldability and resistance to oxidation and retains medium strength, thus being a good fit for industrial and commercial applications. Vinit Stainless is committed to consistent quality and customer satisfaction and makes sure that its tubing items are produced with the latest technology and conform to international standards. This makes them a reliable partner to customers in the automotive, energy, and infrastructure industries.

410S Stainless Steel is a non–hardening, low–carbon variant of 410 Stainless Steel. It contains 11.5–13.5% chromium and ≤0.08% carbon content, together with minor amounts of manganese, silicon, and sulfur. This composition minimizes the hardening risk and enhances weldability. Mechanically, it possesses a tensile strength of about 450 MPa, a yield strength of 280 MPa, elongation of 25%, and a hardness of 80 HRB. All these make it suitable for use in applications where there is a need for moderate corrosion resistance and good formability, particularly under high-temperature conditions.

Specifications : ASTM A731, A268 / ASME SA731, SA268

Dimensions : ASTM, ASME and API

Size : 1/2″ NB to 24″ NB

Type : Seamless, Welded, EFW, ERW, Fabricated

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Form : Round Pipes, Square Pipes, Rectangular Pipes, Oval Pipes, Hydraulic Pipe, etc.

End : Plain End, Treaded, Beveled End

Length : Single Random, Double Random & Cut Length. (Custom Sizes Available as per customers requirement)

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 410s | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 max: 13.5 | 0.50 max |

| Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 410s | 65 (450) | 30 (205) | 20 | 217 | 96 |

Contact us to get a quick quote for your requirement.

This tubing comes in various sizes, typically ranging from 1/8″ to 12″ in diameter. It is known for its moderate corrosion resistance and is often used in applications requiring high strength and toughness.

Available in sizes from 1/4″ to 8″ in diameter, this tubing offers good corrosion resistance and is ideal for applications requiring welded joints. It’s commonly used in structural and high-stress environments.

Typically sized between 1/2″ to 2″ in diameter, this tube is designed for optimal heat transfer and corrosion resistance in heat exchangers. It is suitable for high-temperature applications.

Sizes for this tubing usually range from 1/8″ to 1″ in diameter. It is used in precision instruments and offers moderate corrosion resistance, making it suitable for various analytical and control instruments.

Available in sizes from 1″ to 6″ in diameter, these tubes are designed to withstand high temperatures and pressures in boiler systems. They provide moderate resistance to corrosion in high-heat environments.

Typically used in heat exchangers, these U-tubes come in sizes from 1/2″ to 2″ in diameter. They offer good resistance to corrosion and high durability in cyclic heating and cooling applications.

Usually sized between 1/2″ and 2″ in diameter, these tubes are used in condensers and are designed to resist corrosion and handle high thermal stress efficiently.

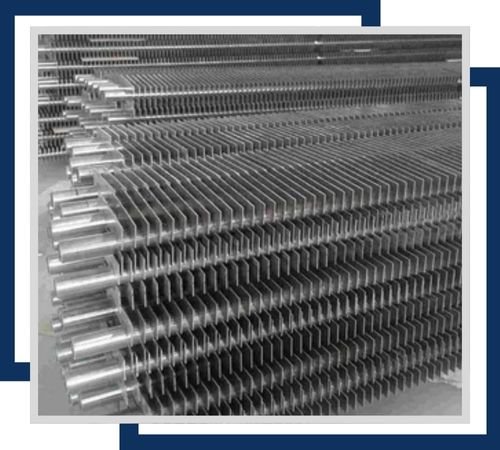

Fin tubes come in various diameters, typically from 1/2″ to 2″ with extended fins for enhanced heat transfer. They provide good resistance to corrosion and are used in heat exchangers and cooling systems.

Stainless Steel 410S Tubing finds extensive use in high-temperature and oxidizing conditions such as in automotive exhaust systems, industrial boilers, and heat exchangers. It is particularly useful in situations where weldability and oxidation are of the utmost importance. Petrochemicals, refineries, and thermal process industries employ 410S tubing in radiant tubes and furnace parts. Having a low carbon content reduces weld cracking and scaling risk and makes it appropriate for welded construction components that are exposed to cyclic thermal exposure. The tubing is also employed in ducts, mufflers, and combustion chamber construction because of its structural integrity and heat transfer properties.

©2024 Vinit Stainless All Rights Reserved.