Vinit Stainless, which is established in Chennai, India, is a well-known producer and supplier of high-quality stainless steel products with a specialty in superior-grade tubing solutions. Of their comprehensive product list, SS 305 Tubing is prominent due to its superior formability and corrosion resistance. With the capability to fulfill the demands of industries that need non-magnetic stainless steel, SS 305 Tubing is produced under tight quality controls and in multiple sizes and specifications. Through a robust customer-focused strategy and conformity to international quality standards, Vinit Stainless has acquired a faithful customer base in industries such as automotive, food processing, and chemical.

SS 305 Tubing is an austenitic stainless steel alloy with a main content of 17–19% chromium and 10.5–13% nickel, but lower carbon content and higher nickel to minimize work-hardening. This composition adds formability and corrosion resistance. The tubing generally has a tensile strength of approximately 515 MPa, yield strength of 205 MPa, and elongation of 40%. It is free from magnetism in the annealed state and possesses superior ductility and toughness at cryogenic temperatures. Its characteristics render it especially ideal for deep drawing, spinning, and forming operations without sacrificing strength or durability.

Type: Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes

Grades: TP304, TP304L, TP304H

Size: 1/8” NB to 5” NB, 1/4” OD to 5” OD sizes stainless steel seamless tubes also available

Length: Up to 6 meters, custom cut lengths

Thickness: 1mm to 13mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

Finish: No.1 Pickled Finish, No.4 finish, BA Finish, Electropolished Pipes

Delivery Condition: Hot Finish, Cold Finish, Bright Annealed, Polished, Annealed and Pickled, Passivated, Stress Relived

| Element | Content (%) |

|---|---|

| Iron, Fe | 67 |

| Chromium, Cr | 18 |

| Nickel, Ni | 12 |

| Manganese, Mn | ≤ 2 |

| Silicon, Si | ≤ 1 |

| Carbon, C | 0.12 |

| Phosphorous, P | 0.045 |

| Sulfur, S | 0.030 |

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength, ultimate | 585 MPa | 84800 psi |

| Tensile strength, yield (@0.2%) | 260 MPa | 37700 psi |

| Modulus of elasticity | 193 GPa | 28000 ksi |

| Shear modulus | 86 GPa | 12500 ksi |

| Elongation at break (in 50 mm) | 50 | 50 |

| Hardness, Brinell | 80 | 80 |

| Hardness, Knoop (converted from Brinell hardness) | 97 | 97 |

| Hardness, Rockwell B (converted from Brinell hardness) | 45 | 45 |

| Hardness, Vickers (converted from Brinell hardness) | 82 | 82 |

Contact us to get a quick quote for your requirement.

This tubing comes in a variety of sizes, typically ranging from 1/8″ to 4″ in diameter. Known for its exceptional corrosion resistance and smooth finish, it is ideal for applications requiring high durability and reliability.

Available in sizes from 1/4″ to 6″ in diameter, this tubing features a welded seam for structural strength. It offers excellent corrosion resistance and is commonly used in both industrial and architectural applications.

Designed for heat transfer efficiency, these tubes are generally sized from 1/2″ to 2″ in diameter. They exhibit high resistance to corrosion and are used in heat exchangers for various industrial processes.

Stainless Steel 305 Instrumentation Tubing**: Available in sizes ranging from 1/16″ to 1/2″ in diameter, this tubing is designed for precise instrumentation applications. It offers superior corrosion resistance and is ideal for use in harsh environments and critical measurement systems.

Typically available in sizes from 1″ to 4″ in diameter, these tubes are engineered to withstand high temperatures and pressures. They are highly corrosion-resistant and suitable for boiler systems.

Usually ranging from 1/2″ to 2″ in diameter, these U-shaped tubes are designed for applications such as heat exchangers and condensers. They offer strong corrosion resistance and flexibility in heat transfer systems.

Available in sizes from 1/2″ to 3″ in diameter, these tubes are optimized for use in condensers. They provide excellent resistance to corrosion and scaling, making them ideal for high-performance cooling systems.

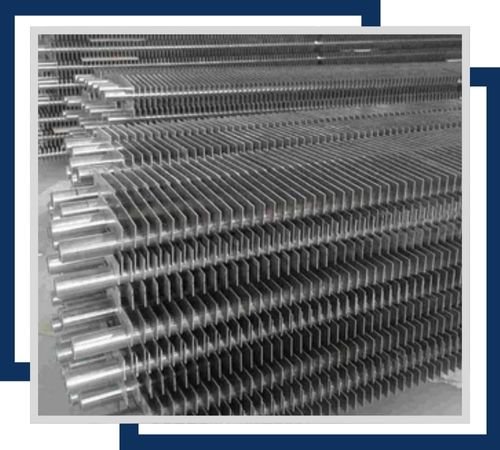

Typically sized from 1″ to 2″ in diameter, these tubes feature finned surfaces for enhanced heat transfer. They are highly resistant to corrosion and are used in various heat exchange and cooling applications.

SS 305 Tubing is extensively employed where higher formability and non-magnetic characteristics are necessary. It is well-suited for deep-drawn products like automotive trim, kitchenware utensils, appliance parts, and electrical components. The tubing can be used in mildly corrosive conditions and is thus suitable for food processing machinery, chemical equipment, and decorative architecture. In addition to this, SS 305 Tubing is also applied in the production of battery containers and other electrical devices having low magnetic permeability requirements. Its good surface finish and flexibility to welding and forming processes make it a generally applicable material across a number of industries, such as medical and consumer goods production.

©2024 Vinit Stainless All Rights Reserved.