Based in Chennai, India, Vinit Stainless is a well-known producer and supplier of high-end stainless steel goods. We provide a broad range of stainless steel solutions suited to industrial needs and are renowned for our commitment to accuracy and quality. Stainless Steel 410 Tubing is one of our main products; it is well-known for its strength, resistance to heat, and moderate resistance to corrosion. This tubing is carefully designed to satisfy the performance requirements of industries such as chemical processing, automotive, and aerospace. Vinit Stainless has established itself as a reputable brand in the Indian stainless steel sector thanks to our unwavering dedication to client satisfaction, prompt delivery, and uncompromising quality.

Designed for improved hardness, strength, and moderate corrosion resistance, Stainless Steel 410 Tubing is a martensitic stainless steel with 11.5–13.5% chromium and up to 0.15% carbon. It is magnetic, has good heat resistance, and can be heat-treated to improve wear resistance and mechanical strength. In addition to having high tensile strength and impact resistance, SS 410 tubing is very machinable. It works well in environments with mild chemicals, steam, or oxidizing conditions, making it appropriate for high-stress applications needing strength and durability, even though it is less corrosion-resistant than austenitic grades.

| Specifications | : | ASTM A/ASME SA213/ A249/ A269 |

| Dimensions | : | ASTM, ASME and API |

| SS 310/ 310S Tubes Size | : | 1/8″NB TO 30″NB IN |

| Schedule | : | SCH20, SCH30, SCH40, XS, STD, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Thickness | : | 0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm. |

| Form | : | Round, Rectangular, Square, Hydraulic Etc |

| Type | : | Seamless / Fabricated / ERW / Welded / LSAW Tubes |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treaded |

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 410 | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 max: 13.5 | 0.50 max |

| Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 410 | 65 (450) | 30 (205) | 20 | 217 | 96 |

Contact us to get a quick quote for your requirement.

We is offering stainless steel 410 tubing with thorough testing and certification. Every batch goes through extensive chemical composition, mechanical properties, and dimensional accuracy to ensure conformance to international standards. The compliance certificates, material traceability, and test reports are given so that there would be quality assurance and performance guarantee for applications of various kinds.

Stainless Steel 410 seamless tubing offers excellent corrosion resistance, high strength, and durability. Ideal for aerospace, automotive, and industrial applications, it ensures reliability and performance in demanding environments.

Stainless Steel 410 welded tubing provides robust corrosion resistance and strength. It’s ideal for applications in petrochemical, automotive, and industrial sectors, offering durability and cost-effectiveness in demanding environments.

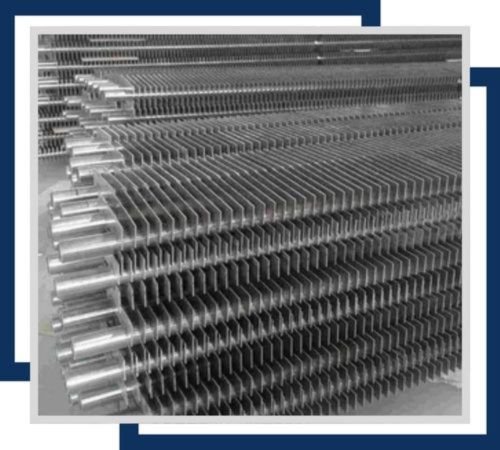

Stainless Steel 410 heat exchanger tubes offer superior corrosion resistance and thermal conductivity. They are ideal for high-temperature applications in chemical processing, oil and gas, and power generation industries.

Stainless Steel 410 instrumentation tubing ensures precise flow control and corrosion resistance. Ideal for chemical, petrochemical, and oil and gas industries, it offers durability and reliability in demanding environments.

Stainless Steel 410 boiler tubes offer excellent corrosion resistance, high strength, and thermal conductivity. Ideal for high-pressure and high-temperature applications in power plants and industrial boilers, ensuring reliable performance.

Stainless Steel 410 U-tubes provide excellent corrosion resistance and strength. They are ideal for heat exchangers and boiler applications, ensuring durability and efficient thermal performance in demanding environments.

Stainless Steel 410 condenser tubes offer high corrosion resistance and thermal efficiency. Ideal for use in power plants and refrigeration, they ensure durability and reliable heat transfer performance.

Stainless Steel 410 fin tubes provide excellent corrosion resistance and enhanced heat transfer efficiency. Ideal for heat exchangers and condensers, they ensure durability and optimal thermal performance in demanding applications.

Many industries that require mechanical strength and heat resistance use stainless steel 410 tubing. Because of its resistance to high temperatures and mildly corrosive environments, it finds use in heat exchangers, food and beverage equipment, and chemical processing facilities. It is used in the manufacturing of shafts, valves, pump parts, and structural assemblies in the automotive and aerospace industries. It is perfect for precision parts subjected to wear and mechanical stress because of its exceptional machinability and hardness. For industrial applications where strength and moderate corrosion resistance are essential, SS 410 tubing offers an affordable and long-lasting solution.

©2024 Vinit Stainless All Rights Reserved.