Vinit Stainless, a quality manufacturer and supplier in Chennai, India, provides high-performance SS 455 Bar. This precipitation hardening stainless steel is designed for applications requiring exceptionally high strength, satisfactory toughness, and superior corrosion resistance. Our SS 455 bars are carefully manufactured to achieve uniform properties and accurate dimensions, and they are used for critical parts in aerospace, defense, and high-performance engineering applications where reliability and strength are absolutely essential.

Stainless Steel 455 is a martensitic precipitation-hardening alloy. Its nominal chemistry contains 11-12.5% Chromium, 7.5-9.5% Nickel, 1.5-2.5% Molybdenum, and 0.8-1.5% Titanium, with Aluminum and Niobium. It can attain very high tensile strengths of 1380-1725 MPa and yield strengths of 1240-1655 MPa after suitable heat treatment. It also has good ductility and toughness, even at these high-strength levels, offering a balanced performance curve.

| Dimension : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Grade : | Custom 455 (UNS No. S45500) Round Bars |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Form : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Surface : | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Application : | Chemical process, Food processing, Petrochemical, Pollution control, Pulp and Paper, Refining |

| Condition : | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished. |

| Grade | C | Mn | Si | Ni | Cr | Ti | Mo | Cb+Ta | Cu |

| Custom 455 | 0.05 max | .50 max | .50 max | 7.50 – 9.50 | 11.00 – 12.50 | .80 – 1.40 | .50 | .10 – .50 | 1.50 – 2.50 |

| Material | Condition | 0.2 % Yield Strength (Mpa) | Ultimate Tensile Strength (Mpa) | Notch Tensile Strength | % Elongation in 4D | % Reduction of Area | Rockwell C Hardness | Charpy V Notch Impact Strength (ft-lbs) |

| Alloy 455 Bar 1″ Section Custom 455® | A | 793 | 1000 | 1585 | 14 | 60 | 31 | 70 |

| Alloy 455 Bar 1″ Section Custom 455® | H900 | 1689 | 1724 | 1792 | 10 | 45 | 49 | 9 |

| Alloy 455 Bar 1″ Section Custom 455® | H950 | 1551 | 1620 | 2068 | 12 | 50 | 48 | 14 |

| Alloy 455 Bar 1″ Section Custom 455® | H1000 | 1379 | 1448 | 2000 | 14 | 55 | 45 | 20 |

| Alloy 455 Bar 1″ Section Custom 455® | H1050 | 1207 | 1310 | 1793 | 15 | 55 | 40 | 35 |

Contact us to get a quick quote for your requirement.

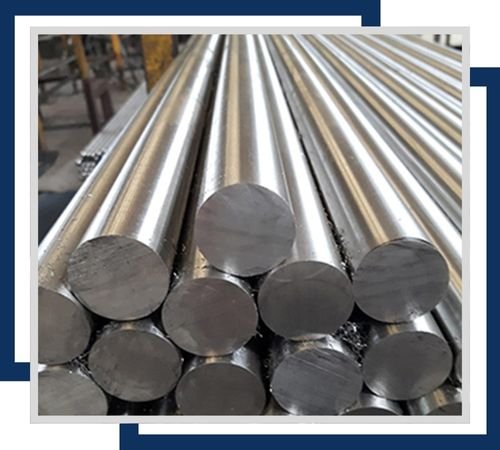

SS 455 Bar Round Bar is a high-performance stainless steel alloy known for its excellent resistance to corrosion and high strength. It offers good weldability and is commonly used in industries like aerospace, chemical, and petrochemical. The round bar form provides versatility for various machining applications, ensuring durability and reliability in harsh environments.

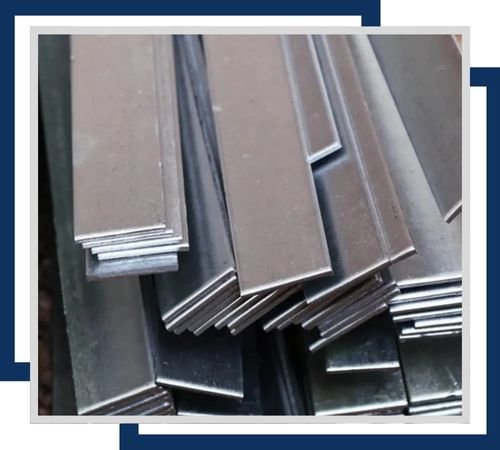

Stainless Steel 455 Flat Bar is a corrosion-resistant alloy with high strength and durability. It offers excellent resistance to pitting, stress, and oxidation, making it suitable for demanding applications in industries such as aerospace, automotive, and chemical processing. The flat bar shape allows for easy machining and fabrication.

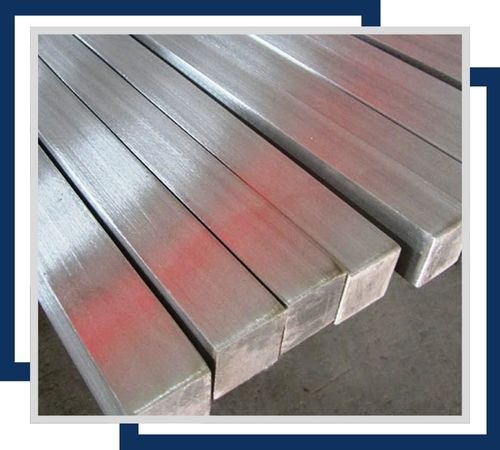

SS 455 Bar Square Bar is a high-strength stainless steel known for its excellent corrosion resistance, particularly in harsh environments. It offers good weldability and durability, making it ideal for applications in industries like aerospace, chemical processing, and manufacturing. Its square shape provides versatility for machining and fabrication.

Stainless Steel 455 Rectangular Bar is a corrosion-resistant alloy known for its high strength, excellent durability, and resistance to oxidation and pitting. It is ideal for demanding environments like aerospace, chemical processing, and marine industries. The rectangular shape allows for easy machining, making it suitable for various fabrication applications.

SS 455 Bar Hexagonal Bar is a high-strength stainless steel with excellent corrosion resistance, making it suitable for harsh environments. Its hexagonal shape provides enhanced grip for various industrial applications, including aerospace, chemical processing, and automotive. It offers good machinability, durability, and reliability for critical manufacturing and fabrication needs.

SS 455 Bar T-Bar is a high-performance stainless steel known for its excellent corrosion resistance and strength. The T-shaped profile provides increased structural support, making it ideal for use in demanding applications like aerospace, chemical processing, and construction. It offers durability, weldability, and ease of machining for various projects.

Stainless Steel 455 Bar finds its major applications in products where superior strength-to-weight ratio and high reliability are demanded. Major applications are in aircraft parts, missile components, and landing gear. It is utilized in high-strength shafts, fasteners, and springs. Its strength, toughness, and corrosion resistance make it suitable for tooling, surgical equipment, and sporting goods. The fact that it retains property when subjected to stress makes it integral for critical structural components.

©2024 Vinit Stainless All Rights Reserved.