Vinit Stainless is a reliable Chennai-based manufacturer and supplier that offers high–quality Stainless Steel 465 Bar. This precipitation-hardenable ultra-high strength stainless steel is tailored for use in applications demanding high strength, superior toughness, and improved stress corrosion cracking resistance. Our SS 465 bars are processed with precision to deliver consistent quality and maximum performance for the most severe engineering and aerospace applications where performance reliability under hostile conditions is a matter of no compromise.

Stainless Steel 465 is a martensitic precipitation-strengthening alloy with a composition generally consisting of 11-12.5% Chromium, 10.5-12.5% Nickel, 0.75-1.5% Molybdenum, and 1.5-2.5% Titanium, with minor amounts of Niobium. When heat-treated, it has ultimate tensile strengths in excess of 1700 MPa (250 ksi) and yield strengths in excess of 1500 MPa (220 ksi). The alloy also exhibits excellent toughness and enhanced resistance to stress corrosion cracking over that of other high-strength steels.

| Specification : | ASTM F-899 / AMS 5936 |

| Standard : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round Bars : | Outside Diameter in the range of 4mm to 500mm |

| Bright Bars : | Outside Diameter in the range of 4mm to 100mm |

| Hex Bars : | 18mm – 57mm (11/16″ to 2-3/4″) |

| Square Bars : | 18mm – 47mm (11/16″ to 1-3/4″) |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length : | 1 to 6 Meters, Custom Cut Lengths |

| Form : | Round, Square, Hex (A/F), Rectangle Etc. |

| Chemical Composition Limits | ||||||||||||

| Weight% | Mn | S | Cr | Mo | Ti | Fe | C | P | Si | Ni | Cu | Nb Ta |

| Alloy 465 | 0.50 max | 0.030 max | 11.00 – 12.50 | 0.50 max | 0.80 – 1.40 | Balance | 0.05 max | 0.040 max | 0.50 max | 7.50 – 9.50 | 1.50 – 2.50 | 0.10 – 0.50 |

| Material | Condition | Orientation | 0.2 % Yield Strength (Mpa) | Ultimate Tensile Strength (Mpa) | % Elongation in 4D | % Reduction of Area | Notch Tensile Strength | NTS/UTS | Charpy V Notch Impact | Rockwell C Hardness |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H950 | Long | 1655 | 1765 | 12 | 57 | 2475 | 1.40 | 16 | 49.5 |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H950 | Trans | 1648 | 1765 | 11 | 49 | 2386 | 1.35 | 13 | 49.5 |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H1000 | Long | 1496 | 1593 | 14 | 63 | 2427 | 1.52 | 35 | 47.5 |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H1000 | Trans | 1503 | 1600 | 13 | 57 | 2392 | 1.50 | 28 | 47.5 |

Contact us to get a quick quote for your requirement.

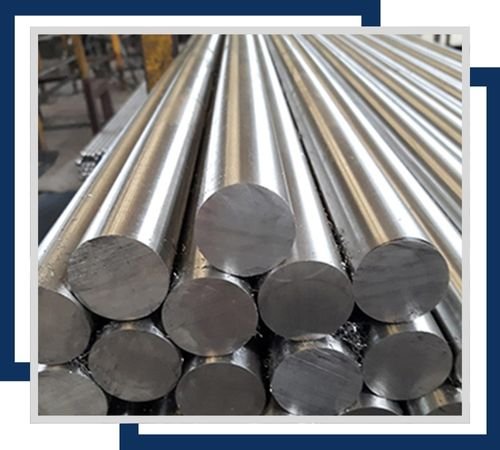

SS 465 Bar Round Bar is a high-strength stainless steel alloy known for its excellent resistance to corrosion and wear. It is widely used in industries requiring robust performance, such as aerospace, chemical processing, and manufacturing. Available in various sizes, it offers durability and long-lasting functionality in harsh environments.

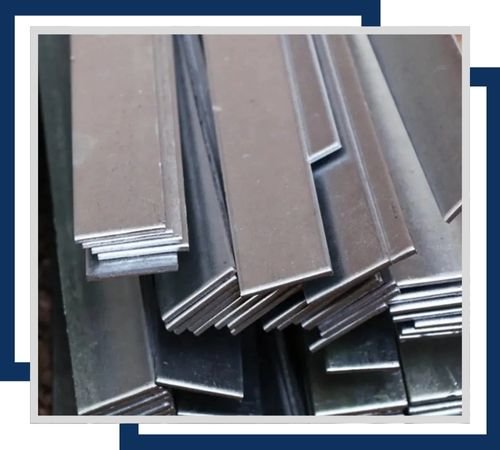

Stainless Steel 465 Flat Bar is a high-performance alloy known for its excellent resistance to corrosion, high temperature, and stress. It is commonly used in aerospace, automotive, and chemical industries due to its strength and durability. The flat bar form offers versatility for a range of structural and engineering applications.

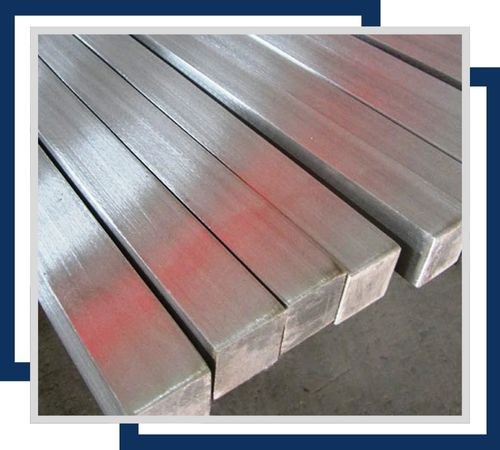

SS 465 Square Bar is a high-strength stainless steel alloy with excellent corrosion resistance, especially in harsh environments. It is commonly used in industries like aerospace, automotive, and chemical processing. The square bar shape allows for easy machining and fabrication, providing versatility for structural and precision applications requiring durability.

Stainless Steel 465 Rectangular Bar is a high-performance alloy offering excellent corrosion resistance, strength, and durability, even in extreme conditions. It is widely used in aerospace, automotive, and chemical industries. The rectangular shape provides flexibility for various structural and engineering applications, ensuring reliability and long-lasting performance in demanding environments.

SS 465 Hexagonal Bar is a high-strength stainless steel alloy known for its excellent corrosion resistance and durability in harsh environments. It is commonly used in industries such as aerospace, automotive, and manufacturing. The hexagonal shape provides enhanced grip and unique design advantages, ideal for custom machining and structural applications.

SS 465 T-Bar is a high-strength stainless steel alloy known for its excellent corrosion resistance and durability. Commonly used in aerospace, automotive, and industrial applications, the T-bar shape provides structural stability and ease of installation. Its superior performance in extreme environments makes it ideal for demanding engineering and fabrication projects.

Stainless Steel 465 Bar is largely applied in aerospace and defense sectors for significant structural parts. Its ultra-high strength and toughness make it suitable for landing gear, aircraft fasteners, shafts, and other highly stressed components. It‘s also used in sports equipment of high performance, medical devices, and tooling where greater strength and resistance to environmental degradation are the top priority. The material’s strong properties guarantee longevity and safety under harsh operational conditions.

©2024 Vinit Stainless All Rights Reserved.