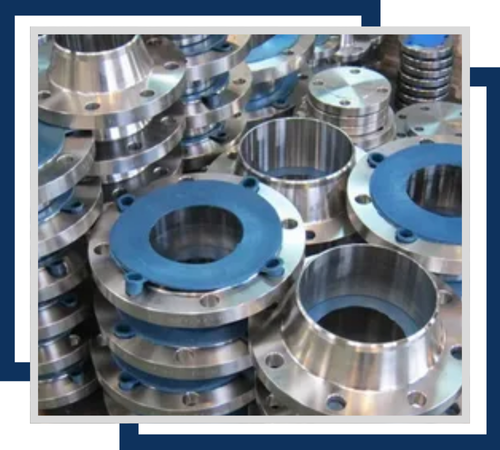

SS 310H flanges are high-carbon austenitic stainless steel flanges that are used particularly for high-temperature service. Produced by Vinit Stainless in Chennai, India, the flanges are used extensively in thermal processing, furnace components, and high-temperature structural parts. The higher carbon content in 310H enhances its high-temperature strength and creep resistance and thus is well suited for applications with thermal cycling and long-term heat exposure. Vinit Stainless guarantees top-quality, dimensional accuracy, and international standards compliance for sectors like petrochemical, power generation, and refineries. SS 310H flanges provide long-lasting endurance and reliability in harsh temperature conditions.

SS 310H flanges consist of 24–26% Chromium, 19–22% Nickel, and an increased Carbon content (0.04–0.10%). This high carbon enhances creep resistance and mechanical properties at high temperatures. These flanges provide a tensile strength of around 515 MPa and a yield strength of 205 MPa. The alloy provides toughness and resistance to oxidation up to a temperature of 1100°C in continuous service. SS 310H flanges provide sound ductility, weldability, and formability while possessing excellent performance in corrosion and high-temperature conditions, especially where thermal stress occurs on a regular basis.

| Standard | ASTM A182 / ASME SA182 |

| Dimensions | ANSI/ASME B16.5, B 16.47 A & B, B16.48, BS4504, BS 10, EN-1092, DIN |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class/Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 310H | min. | 0.04 | – | – | – | – | 24.0 | – | 19.0 | – |

| max. | 0.10 | 2.00 | 1.00 | 0.045 | 0.030 | 26.0 | 21.0 | |||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 310H | 515 | 205 | 40 | 95 | 217 |

Contact us to get a quick quote for your requirement.

SS 310H socket weld flanges are high-quality stainless steel components designed for secure, high-pressure connections in piping systems. They offer excellent resistance to oxidation and corrosion at elevated temperatures.

SS 310H ring type joint flanges provide a robust seal in high-pressure and high-temperature applications. Crafted from stainless steel, they offer superior resistance to oxidation and corrosion for reliable performance.

SS 310H forged flanges are durable stainless steel components, forged for enhanced strength and reliability. They excel in high-temperature and corrosive environments, ensuring secure, long-lasting connections in demanding applications.

SS 310H long weld neck flanges are robust stainless steel fittings designed for high-pressure applications. Their extended neck provides strength and stability, making them ideal for critical, high-temperature environments.

SS 310H lap joint flanges are versatile stainless steel components designed for ease of assembly and disassembly. They offer excellent resistance to high temperatures and corrosion, making them ideal for dynamic applications.

SS 310H reducing flanges facilitate the transition between different pipe sizes in high-temperature systems. Made from stainless steel, they offer exceptional strength and corrosion resistance, ensuring reliable performance under demanding conditions.

SS 310H flanges are suitable for heat treatment machinery, furnace components, kilns, steam boilers, and thermal processing facilities. Their increased carbon content provides them with increased creep strength and mechanical integrity under severe heat conditions. They find applications in petrochemical refineries, power plants, and high-temperature exhaust systems where constant or cyclic heat exposure is imminent. SS 310H flanges also work well in oxidizing and mildly carburizing atmospheres. Because of their durability and resistance under thermal stress, they are selected for use in conditions where lesser-grade alloys would deteriorate with high pressure and extended heat.

©2024 Vinit Stainless All Rights Reserved.