Premium Stainless Steel 310H Bars for high-temperature industrial applications are available from Vinit Stainless, a well-known stainless steel manufacturer and supplier with headquarters in Chennai, India. A high-carbon variant of 310, SS 310H is renowned for its superior strength and exceptional resistance to creep and oxidation at high temperatures. Vinit Stainless manufactures 310H bars in a range of sizes and finishes to satisfy both custom and international standards. Industries including petrochemical, power generation, thermal processing, and refineries make extensive use of our bars. We provide performance-driven solutions that satisfy the most exacting service requirements through meticulous engineering and stringent quality control.

| Specifications | ASTMA276 / A479, ASME SA276 / A479 |

|---|---|

| Dimensions | EN, DIN, JIS, ASTM. BS, ASME, AISI |

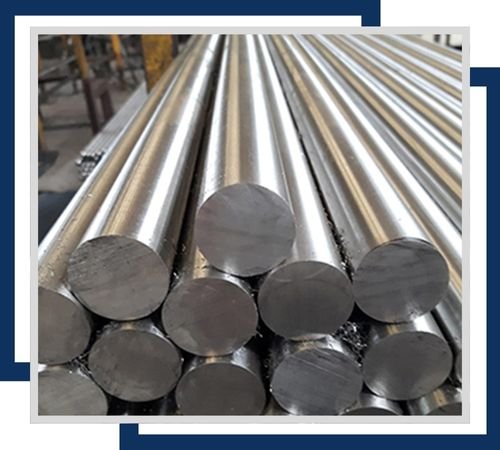

| SS 310H Round Bar | Outside Diameter in the range of 4mm to 500mm |

| SS 310H Bright Bar | Outside Diameter in the range of 4mm to 100mm |

| SS 310H Hex Bar | 18mm – 57mm (11/16″ to 2-3/4″) |

| SS 310H Square Bars | 18mm – 47mm (11/16″ to 1-3/4″) |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 1 to 6 Meters, Custom Cut Length |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 310H | 0.10 max | 2.00 max | 1.00 max | 0.045 max | 0.030 max | 24.0 – 26.0 | – | 19.0 – 21.0 | – |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness Rockwell B (HR B) max | Hardness Brinell (HB) max |

| 310H | 515 | 205 | 40 | 217 | 92 |

Contact us to get a quick quote for your requirement.

Chromium (24–26%), nickel (19–22%), and a higher carbon content (0.04–0.10%) are added to stainless steel 310H bars to increase their creep resistance and high-temperature strength. These bars have an elongation of roughly 40%, a yield strength of 205 MPa, and a tensile strength of roughly 515 MPa. Even in the face of severe heat stress, the austenitic structure guarantees exceptional toughness. SS 310H is perfect for welded high-temperature components where structural integrity and long-term durability are crucial because it provides exceptional oxidation resistance up to 1100°C in continuous service.

Stainless Steel 310H Round Bars offer exceptional heat resistance, with diameters ranging from 10mm to 500mm. Ideal for high-temperature applications, such as furnace components and heat exchangers, they provide superior durability and performance.

Stainless Steel 310H Flat Bars are available in thicknesses from 5mm to 100mm and widths from 20mm to 300mm. Suitable for structural and industrial applications, they deliver high strength and resistance to elevated temperatures.

Stainless Steel 310H Square Bars, ranging from 10mm to 150mm, are designed for extreme heat environments. These bars are commonly used in furnace parts and high-temperature equipment, providing excellent thermal stability and strength.

Stainless Steel 310H Rectangular Bars come in thicknesses from 5mm to 75mm and widths from 20mm to 200mm. Ideal for structural supports and high-temperature applications, they offer durability and reliable performance.

Stainless Steel 310H Hexagonal Bars, with dimensions from 10mm to 100mm across flats, are perfect for high-heat applications. These bars provide excellent heat resistance and are used in various industrial settings.

Stainless Steel 310H Bars are available in various forms and sizes, including round, flat, square, and hexagonal. They offer superior heat resistance and are ideal for use in high-temperature environments, ensuring long-term durability and performance.

Power plants, petrochemical refineries, and furnace components are just a few of the high-temperature, high-stress settings that frequently use stainless steel 310H bars. Applications like heat exchanger tubes, boiler parts, burners, combustion chambers, and other parts subjected to high temperatures and oxidising agents are perfect for them. Because of its exceptional mechanical strength and thermal stability, SS 310H can be used in pressure-bearing and structural applications in incinerators and thermal processing facilities. Reliability and longevity in demanding industrial operations are ensured by its resistance to creep, oxidation, and corrosion under temperature fluctuations.

©2024 Vinit Stainless All Rights Reserved.