With its headquarters located in Chennai, India, Vinit Stainless is a well-known leader in the manufacturing and distribution of high-end stainless steel products. The company, which is well-known for its quality-driven approach, offers long-lasting and effective solutions for a range of industrial sectors. Stainless Steel 316Ti Bars, one of its main products, are designed to endure harsh environments and provide exceptional mechanical strength and corrosion resistance. Because of their dependability in challenging and corrosive conditions, these bars are widely used in the chemical processing, marine, and construction industries. Vinit Stainless is still a well-known brand in the stainless steel industry thanks to its emphasis on client satisfaction, prompt delivery, and product innovation.

The austenitic stainless steel alloy known as 316Ti bars is made up of 0.5–0.7% titanium, 10–14% nickel, and 16–18% chromium. Titanium improves intergranular corrosion resistance, particularly in high-temperature applications. These bars have exceptional mechanical qualities, such as an approximate tensile strength of 515 MPa, a yield strength of 205 MPa, and an elongation of 35–40%. Additionally, SS 316Ti exhibits outstanding resistance to stress corrosion cracking, pitting, and crevice corrosion, which makes it perfect for extended use in harsh environments. Even when subjected to heat stress, the bars retain their structural integrity and weldability.

| Standard | ASTM A276, A479 / ASME SA276, SA479 |

|---|---|

| Range | 3.17 MM TO 350 MM DIA |

| Diameter | 25mm to 152mm |

| Size Tolerance | h8, h9(DIN 671), h10, h11, ASTM A484, DIN 1013 |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wiremesh, Billet, Ingot, Forging Etc. |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316Ti | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.395 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

We offers high quality stainless steel 316Ti frames, thoroughly tested to ensure durability and reliability. Each team undertakes rigorous quality assurance research, including chemical composition analysis, mechanical testing and validation measurements. Our products come with the right certifications, which meet industry standards for superior performance and customer satisfaction.

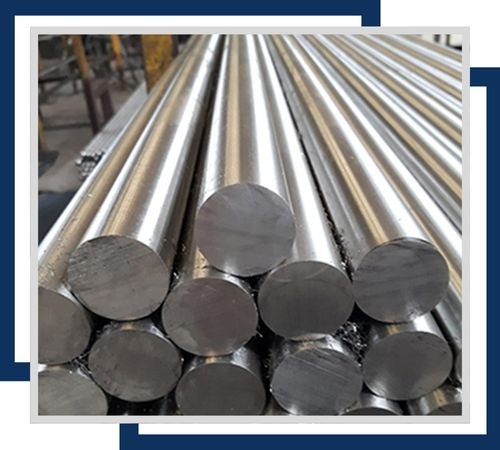

Corrosion-resistant Stainless Steel 316Ti Round Bars come in diameters ranging from 6mm to 250mm. These bars offer excellent strength and are used in high-temperature environments, including chemical and marine industries.

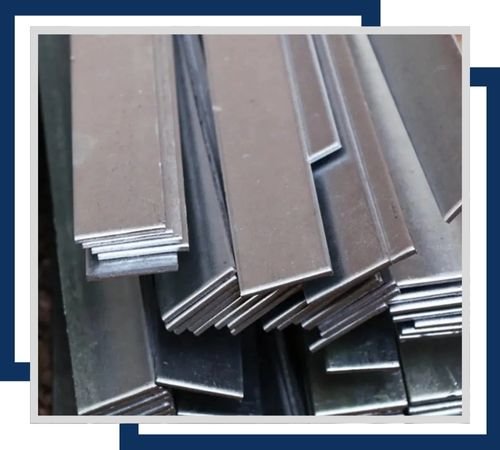

Stainless Steel 316Ti Flat Bars, available in widths from 10mm to 250mm and thicknesses from 5mm to 30mm, are ideal for structural and architectural applications, offering superior resistance to oxidation and corrosion.

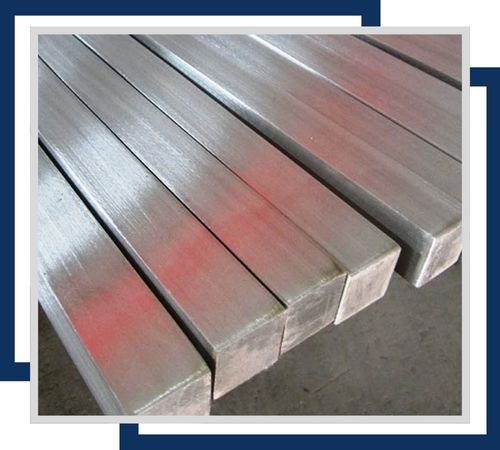

Stainless Steel 316Ti Square Bars are offered in sizes from 10mm to 150mm. Their robust composition makes them suitable for high-stress applications, including marine and chemical processing industries.

Stainless Steel 316Ti Rectangular Bars are available in various dimensions, such as 20mm x 10mm to 200mm x 100mm. They are highly resistant to corrosion and are used in demanding environments like petrochemical plants.

With sizes ranging from 10mm to 100mm, Stainless Steel 316Ti Hexagonal Bars provide excellent strength and corrosion resistance. They are commonly used in aerospace and industrial applications.

Corrosion-resistant Stainless Steel 316Ti T-Bars are available in dimensions such as 20mm x 20mm with varying lengths. They are used in structural frameworks and heavy-duty applications where durability is essential.

Industries that require exceptional corrosion resistance and high strength frequently use stainless steel 316Ti bars. They are especially appropriate for applications involving materials exposed to chlorides and acidic media, such as chemical processing, oil and gas, and marine engineering. Because of their stability at high temperatures, these bars are also perfect for boilers, furnace parts, heat exchangers, and construction structures. They are appropriate for welded applications and have increased durability because of the titanium content, which inhibits carbide precipitation. Furthermore, SS 316Ti bars are employed in the pulp and paper, food processing, and pharmaceutical industries where strength, long-term dependability, and cleanliness are essential.

©2024 Vinit Stainless All Rights Reserved.