Reputable manufacturer and supplier Vinit Stainless, with headquarters in Chennai, India, provides premium stainless steel 314 bars that are renowned for their outstanding performance in corrosive and high-temperature conditions. Vinit Stainless supplies industries throughout India and overseas markets with precisely engineered 314 bars, emphasising quality, dependability, and adherence to international standards. Applications requiring exceptional oxidation resistance and structural strength under heat frequently use these bars. Vinit Stainless provides reliable stainless steel solutions to important industries like furnace manufacturing, heat treatment, chemical processing, and power generation by utilising cutting-edge manufacturing technologies and skilled quality control.

The main constituents of stainless steel 314 bars are 24–26% chromium, 19–22% nickel, and up to 0.25% carbon, with trace amounts of silicon and manganese. They are more resistant to oxidation and scaling at temperatures as high as 1150°C because of their high chromium and nickel content. These bars have good elongation and toughness, with a minimum tensile strength of about 620 MPa and a yield strength of 310 MPa. The alloy can withstand prolonged exposure to heat and thermal cycling without losing its strength or durability because it retains its mechanical integrity at high temperatures.

Specification : ASTM A276, A479 / ASME SA276, SA479

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

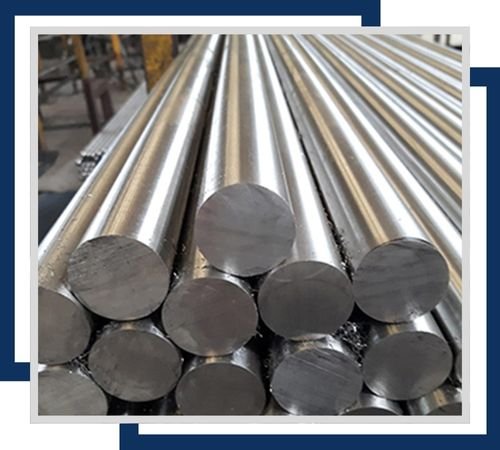

Round Bars : Outside Diameter in the range of 4mm to 500mm

Bright Bars : Outside Diameter in the range of 4mm to 100mm

Hex Bars : 18mm – 57mm (11/16″ to 2-3/4″)

Square Bars : 18mm – 47mm (11/16″ to 1-3/4″)

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Length : 1 to 6 Meters, Custom Cut Lengths

Form : Round, Square, Hex (A/F), Rectangle Etc.

| Element | Content (%) |

|---|---|

| Iron, fe | Balance |

| Chromium, Cr | 19-26 |

| Nickel, Ni | 19-22 |

| Manganese, Mn | 2 |

| Silicon, Si | 1.5-3 |

| Carbon, C | 0.25 |

| Sulfur, S | 0.03 |

| Phosphorous, P | 0.045 |

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 689 MPa | 99900 psi |

| Yield strength | 345 MPa | 50000 psi |

| Modulus of elasticity | 200 GPa | 29000 ksi |

| Elongation at break (in 50 mm) | 40% | 40% |

| Hardness, Rockwell B | 85 | 85 |

Contact us to get a quick quote for your requirement.

Corrosion-resistant and designed for high-temperature applications, Stainless Steel 314 Round Bars are available in diameters from 0.5″ to 12″. Ideal for use in industrial equipment and heat exchangers.

Stainless Steel 314 Flat Bars offer excellent resistance to high temperatures, available in thicknesses from 0.25″ to 6″ and widths up to 12″. Perfect for structural components and industrial uses.

Featuring superior heat resistance, Stainless Steel 314 Square Bars come in sizes from 0.5″ to 6″ on each side. They are suitable for applications requiring high strength and thermal stability.

Stainless Steel 314 Rectangular Bars provide excellent high-temperature resistance, available in sizes from 0.5″ x 1″ to 6″ x 12″. Ideal for heavy-duty applications and components exposed to extreme conditions.

Offering exceptional heat resistance, Stainless Steel 314 Hexagonal Bars are available in sizes from 0.5″ to 4″ across flats. Suitable for aerospace and chemical processing applications requiring durable performance.

Corrosion-resistant Stainless Steel 314 T-Bars come in dimensions from 0.5″ x 0.5″ to 6″ x 6″. They are ideal for structural applications and machinery needing high-temperature strength and durability.

Because of their superior oxidation resistance and structural stability, stainless steel 314 bars are widely used in high-temperature industrial applications. They are perfect for combustion chambers, burners, muffles, radiant tubes, heat treatment baskets, and furnace parts. They are appropriate for use in power plants, petrochemical refineries, cement industries, and steel plants due to their resistance to high heat and thermal cycling. Conveyor belts for annealing furnaces and other heat-handling equipment also use these bars. In crucial heat-resistant engineering applications, 314 bars’ exceptional performance in corrosive and hot conditions guarantees dependable, long-lasting operation.

©2024 Vinit Stainless All Rights Reserved.