Premium-grade stainless steel 316L bars are available from Vinit Stainless, a reputable manufacturer and supplier with headquarters in Chennai, India. These bars are made to satisfy the needs of applications requiring high strength and resistance to corrosion. Vinit Stainless, which is renowned for its dedication to quality and conformity to global standards, produces goods that guarantee strong performance even in the most demanding conditions. The company provides 316L bars to industries like chemical processing, marine, oil & gas, and pharmaceuticals. It has a state-of-the-art production facility and a highly qualified technical staff. In both domestic and international markets, Vinit Stainless is known for its prompt delivery, affordable prices, and reliable customer support.

Stainless Steel 316L Bars are composed of 16–18% chromium, 10–14% nickel, 2–3% molybdenum, and low carbon content (max 0.03%) for improved weldability and corrosion resistance. The addition of molybdenum enhances pitting and crevice corrosion resistance in chloride-rich environments. Mechanically, 316L bars have a minimum tensile strength of 485 MPa, yield strength of 170 MPa, and elongation of 40%. They maintain strength and ductility in both low and high-temperature conditions, making them ideal for demanding applications where both formability and resistance to harsh chemicals are essential.

| Specification | EN 10272, EN 10088-3 Grade 1.4404 |

|---|---|

| Standard | GB, UNS, AISI, SUS, API, ASME, ASTM, DIN, EN |

| Sizes | 3mm to 800mm diameter |

| Length |

|

| Finish | Centreless Ground, Bright, Rough Turned, Black, Peeled, Bright Drawn, Polished, Smooth Turned, Annealed, Grinding, Cold Drawn Turned |

| Tolerances | K10, H10, H11, H8, H13, K12, K9, K11, H12, H9 |

| Surface Finish | HL, BA, NO.4, 1D, 8K, 2D, NO.3, NO.1, 2B |

| Production Method | Rolled / Forged |

| Characteristics |

|

| Value Added Services at Suraj Metal |

|

| Other available forms | T-Bar, Rod, Profiles, Forging,. Blocks, Billet, Ingot, Angle, Rectangle, Half-Round, I/H, Rounds, Precision-Ground, Triangle, Threaded, Hollow, Channel |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

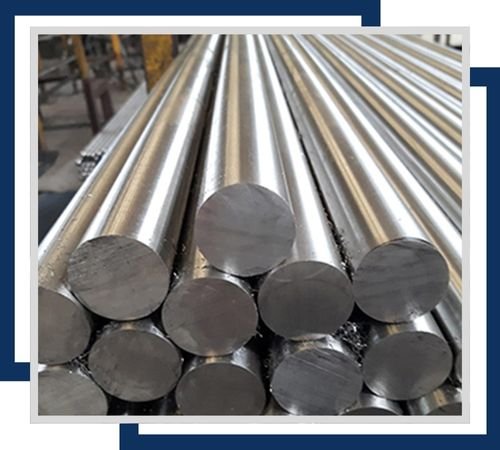

Stainless Steel 316L Round Bars are known for their excellent corrosion resistance and low carbon content, making them ideal for use in marine environments, chemical processing, and pharmaceutical industries. Their low carbon content improves weldability and reduces carbide precipitation.

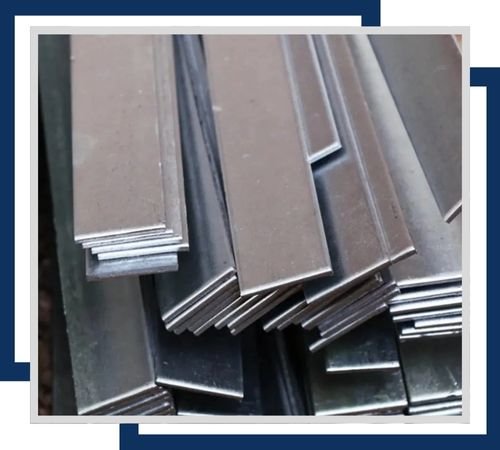

Stainless Steel 316L Flat Bars offer superior resistance to corrosion and excellent machinability. These bars are commonly used in architectural applications, chemical processing equipment, and marine environments where durability and a smooth finish are essential.

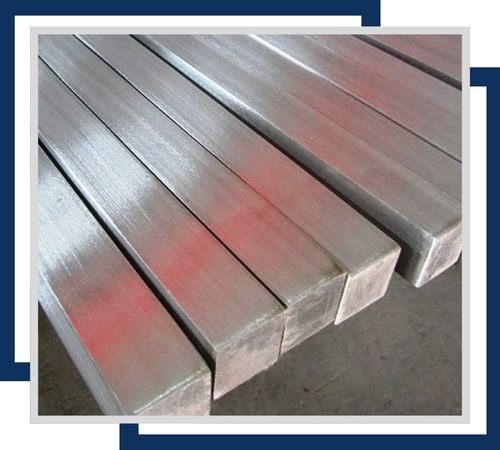

Stainless Steel 316L Square Bars provide excellent corrosion resistance and strength, suitable for use in marine, chemical processing, and medical applications. Their low carbon content enhances their resistance to localized corrosion and improves weldability.

Stainless Steel 316L Rectangular Bars are designed for applications requiring exceptional corrosion resistance and high strength. They are commonly used in the food processing, pharmaceutical, and marine industries, where reliability and resistance to harsh environments are crucial.

Stainless Steel 316L Hexagonal Bars offer excellent corrosion resistance and durability, making them suitable for use in chemical processing, marine applications, and manufacturing of precision components. Their low carbon content ensures enhanced weldability and resistance to pitting.

Stainless Steel 316L T-Bars are used in environments where superior corrosion resistance and strength are required. Ideal for structural applications, chemical processing equipment, and marine components, these bars offer durability and performance with improved weldability.

Stainless steel 316L bars are frequently utilised in settings that demand exceptional strength and resistance to corrosion, particularly in chloride and maritime environments. Heat exchangers, pharmaceutical manufacturing, marine components, food and beverage processing systems, and chemical and petrochemical equipment are examples of common applications. They are perfect for fabrication without the risk of carbide precipitation because of their low carbon content, which guarantees excellent weldability. These bars are also utilised in the pulp and paper, medical implant, and architectural industries. 316L bars are a versatile material for a wide range of crucial industrial applications because of their strength, formability, and hygienic qualities.

©2024 Vinit Stainless All Rights Reserved.