Based in Chennai, India, Vinit Stainless is a well-known producer and supplier of premium 309S stainless steel bars. 309S bars are made to survive harsh industrial conditions and are well-known for their remarkable resistance to heat and corrosion. Vinit Stainless guarantees that these bars are produced using cutting-edge technology and stringent quality controls, satisfying international standards. Our 309S bars are used in vital sectors like aerospace, petrochemical, and power generation, where resistance to oxidation and high temperatures are essential. Delivering strong, high-performing bars that provide dependable service life even in the most challenging operating environments is something we take great pride in.

In order to enhance weldability and reduce carbide precipitation, stainless steel 309S bars have a low carbon content (≤0.03%) and a high chromium (23–25%) and nickel (12–15%) content. Excellent resistance to oxidation and high-temperature scaling is provided by this composition. 309S bars normally have tensile strengths of about 515 MPa, yield strengths of about 205 MPa, and elongations of about 40%. At temperatures as high as 1200°C, the austenitic microstructure guarantees good toughness and thermal stability. These bars are perfect for heavy-duty, high-temperature applications because of their exceptional resistance to creep and oxidation.

| Grade | Stainless Steel 309S (UNS 30908) |

| Standard | ASTM A276 / ASME SA276 |

| Diameter | 25mm to 152mm dia |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Finish | Bright, Polish & Black |

| Type | Round/Square/ Hexagonal/ Rectangular |

Element | Content (%) |

Iron, Fe | 60 |

Chromium, Cr | 23 |

Nickel, Ni | 14 |

Manganese, Mn | 2 |

Silicon, Si | 1 |

Carbon, C | 0.20 |

Phosphorous, P | 0.045 |

Sulfur, S | 0.030 |

Properties | Metric | Imperial |

Tensile strength | 620 MPa | 89900 psi |

Yield strength (@ strain 0.200%) | 310 MPa | 45000 psi |

Izod impact | 120 – 165 J | 88.5 – 122 ft-lb |

Shear modulus (typical for steel) | 77 GPa | 11200 ksi |

Elastic modulus | 200 GPa | 29008 ksi |

Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

Elongation at break (in 50 mm) | 45% | 45% |

Hardness, Brinell | 147 | 147 |

Hardness, Rockwell B | 85 | 85 |

Hardness, Vickers (converted from Rockwell B hardness) | 169 | 169 |

Contact us to get a quick quote for your requirement.

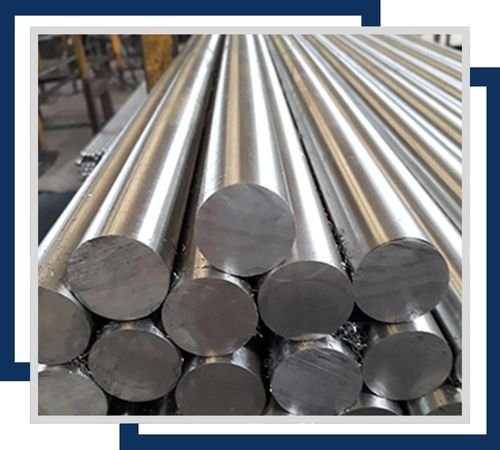

Stainless Steel 309S Round Bars are designed for high-temperature applications, offering exceptional oxidation resistance and durability. They are ideal for components in furnaces, heat exchangers, and other high-heat environments.

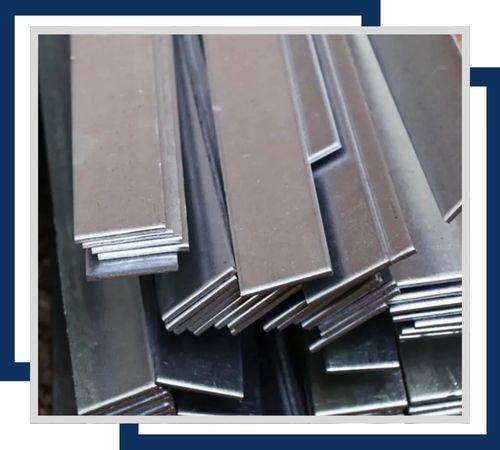

Stainless Steel 309S Flat Bars provide outstanding heat resistance and strength, suitable for applications such as heat shields, furnace parts, and structural components exposed to high temperatures and corrosive environments.

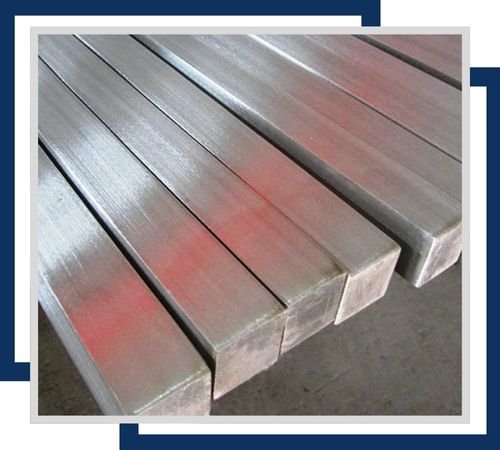

Stainless Steel 309S Square Bars are used in high-temperature settings where heat resistance and durability are critical. They are commonly employed in manufacturing parts for the aerospace industry, industrial equipment, and heat exchangers.

Stainless Steel 309S Rectangular Bars are ideal for high-temperature applications requiring superior oxidation resistance. They are often used in furnace components, structural supports, and industrial parts that endure extreme heat and corrosive conditions.

Stainless Steel 309S Hexagonal Bars are perfect for applications needing high-temperature performance and corrosion resistance. They are utilized in industrial processes, furnace parts, and equipment subjected to severe thermal conditions.

Stainless Steel 309S T-Bars offer excellent heat resistance and strength, making them suitable for high-temperature structural applications. They are commonly used in heat exchangers, support structures, and furnace components.

Stainless steel 309S bars are frequently utilised in settings that demand resistance to corrosion and high temperatures. They are perfect for producing boiler components, kiln linings, heat exchangers and furnace parts. These bars are used in petrochemical, power generation, aerospace, and steel processing industries because they are resistant to oxidation and scaling at high temperatures. Additionally, 309S bars are utilised in the production of exhaust parts, thermal processing machinery, and structural elements that are subjected to extreme heat. They are a popular option for crucial applications requiring long-term performance in demanding thermal environments because of their exceptional weldability and durability.

©2024 Vinit Stainless All Rights Reserved.