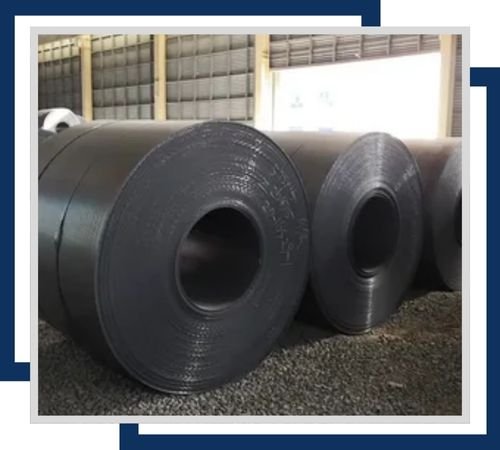

Vinit Stainless, a reputable manufacturer and supplier of stainless steel 410 coils with its headquarters located in Chennai, India, offers dependable and high-performing stainless steel solutions for a range of industrial applications. Our SS 410 coils are made with high-quality raw materials and cutting-edge production processes to guarantee exceptional strength, machinability, and wear resistance. We provide coils that meet international standards and are suitable for thermal, mechanical, and structural applications because we are steadfast in our commitment to quality and accuracy. Vinit Stainless provides competitive pricing, prompt delivery, and unrivalled customer support to a variety of industries, including engineering, power generation, automotive, and fabrication.

The martensitic stainless steel alloy used to make Stainless Steel 410 Coils is made up of 11.5–13.5% chromium and roughly 0.15% carbon, with trace amounts of silicon, phosphorus, and manganese. Strength, hardness, and corrosion resistance are all well-balanced in this composition. The coils have a yield strength of about 275 MPa and a tensile strength of 500–700 MPa. SS 410 can achieve a hardness of up to 35 HRC with the right heat treatment. These coils are appropriate for applications needing moderate corrosion resistance and mechanical durability because of their good ductility and machinability.

| Standard | ASTM A240, ASME SA240 |

| Thickness | 0.1mm to 12 mm Thk |

| Coil Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm etc. |

| Coil Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm etc. |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sandblast, Brush, etching. |

| Finish | Hot rolled (HR), Cold rolled (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated), Galvanized etc. |

| Tensile Strength(MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Rockwell B (HRB) max | Brinell (HB) max |

| 450 | 240 | 25 | 75 | 131 |

| Grade | C | Ni strong> | Si | S | Mn | P | Cr | Ti | |

| SS 410 | Min | – | – | – | – | – | – | 10.5 | 6x C |

| MAX | 0.08 | 0.5 | 1.00 | 0.045 | 1.00 | 0.045 | 11.75 | 0.75 | |

| Grade | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 410 | 1.4006 | S41000 | SUS 410 | 410S21 | – | – | X12Cr13 |

Contact us to get a quick quote for your requirement.

SS 410 slitting coils offer high strength, durability, and excellent corrosion resistance. Ideal for precision cutting and industrial applications, they ensure reliability and performance in demanding environments.

SS 410 hot rolled coils provide exceptional strength and toughness, making them ideal for heavy-duty applications. Their superior corrosion resistance and durability ensure reliability in demanding industrial and structural uses.

SS 410 cold rolled coils deliver superior surface finish and dimensional accuracy, offering excellent strength and corrosion resistance. They are ideal for precision applications, including automotive parts and industrial components.

Stainless Steel 410 HR slitting coils combine high strength and durability with excellent corrosion resistance. Ideal for precise cutting and heavy-duty applications, they offer reliable performance and versatility.

Stainless Steel 410 slitting coils are known for their strength and corrosion resistance. Ideal for precision cutting and various industrial uses, they offer durability and reliability in demanding applications.

AISI 410 slitting coils are prized for their high strength, hardness, and corrosion resistance. They are perfect for precision cutting and durable applications, offering reliable performance in industrial settings.

Industries that need high mechanical strength, moderate corrosion protection, and exceptional wear resistance frequently use stainless steel 410 coils. Automobile parts, kitchenware, cutlery, turbine parts, pump and valve parts, and machine housings are among the frequently used applications. Additionally, they are used in the manufacturing, fabrication, and construction of panels, brackets, and other structural elements. SS 410 coils are ideal for mild chemical environments, food industry equipment, and thermal processing units because of their resistance to heat and mechanical stress. They are a popular option for forming and stamping operations due to their affordability and ease of machining.

©2024 Vinit Stainless All Rights Reserved.