High-performance stainless steel 440 bars are available from Vinit Stainless, a renowned manufacturer and supplier with headquarters in Chennai, India, for applications needing remarkable hardness and wear resistance. To ensure exceptional quality, dimensional accuracy, and durability, our SS 440 bars are made with premium raw materials and cutting-edge manufacturing techniques. These bars are ideal for heavy-duty industrial, engineering, and tooling applications because of their exceptional strength and resilience to adverse conditions. Serving a wide range of clients in India and abroad, Vinit Stainless is dedicated to providing dependable stainless steel solutions with prompt delivery and affordable prices.

Stainless Steel 440 Bar is a high-carbon martensitic stainless steel alloy with 0.6–1.2% carbon and roughly 16–18% chromium. It might also contain trace amounts of silicon, manganese, and molybdenum. After the right heat treatment, SS 440, which is well-known for its exceptional hardness and abrasion resistance, can reach a hardness of up to 60 HRC. It offers a high tensile strength of around 760–1000 MPa and good wear resistance. SS 440 performs exceptionally well in settings where strength and hardness are crucial requirements, despite having less corrosion resistance than austenitic grades.

Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

|---|---|---|---|---|---|---|---|

BS | En | No | Name | ||||

440 | S44000 | – | – | – | X105CrMo17 | – | SUS 440 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 440 | min. max. | 0.75 1.20 | – 1 | – 1 | – 0.04 | – 0.03 | 16 18 | – 0.75 | – | – |

|

Tempering Temperature (°C) |

Tensile Strength (MPa) |

Yield Strength 0.2% Proof (MPa) |

Elongation (% in 50mm) |

Hardness Rockwell (HR C) |

Impact Charpy V (J) |

|

Annealed* |

758 |

448 |

14 |

269HB max# |

– |

|

204 |

2030 |

1900 |

4 |

59 |

9 |

|

260 |

1960 |

1830 |

4 |

57 |

9 |

|

316 |

1860 |

1740 |

4 |

56 |

9 |

|

371 |

1790 |

1660 |

4 |

56 |

Contact us to get a quick quote for your requirement.

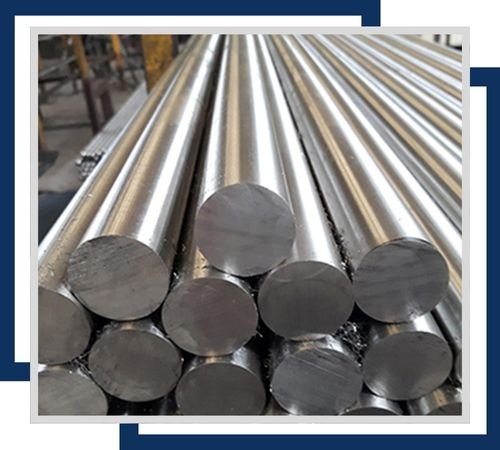

440 round bars offer high hardness and wear resistance, ideal for making cutting tools, blades, and industrial components requiring strength and durability in moderate corrosive environments.

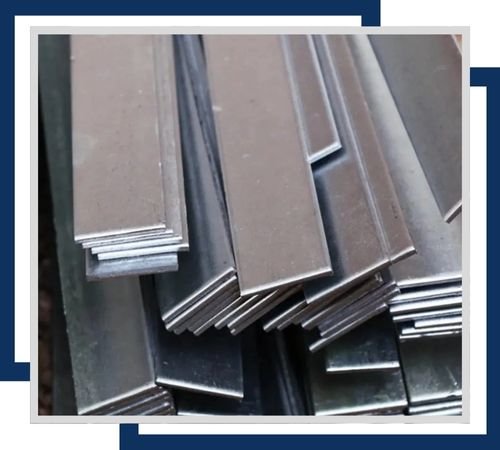

440 flat bars are known for their hardness and abrasion resistance, making them suitable for manufacturing components like blades, tools, and mechanical parts in various industrial applications.

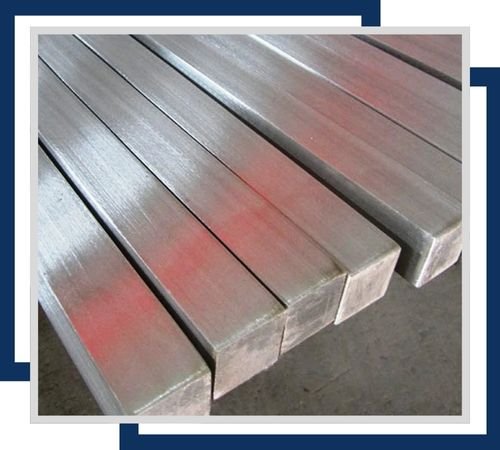

440 square bars provide excellent strength and durability, ideal for applications requiring high wear resistance, such as tooling and machinery components, with good performance in moderate corrosive environments.

440 rectangular bars are used in high-strength applications requiring durability and hardness, such as manufacturing tools, bearings, and structural components, offering excellent wear resistance and moderate corrosion resistance.

440 hexagonal bars deliver high hardness and resistance to wear, suitable for applications like cutting tools and industrial machinery components, providing strength and durability in various environments.

440 T-bars offer robust hardness and wear resistance, ideal for structural applications and tooling, providing strength and durability in environments where high performance and resistance to abrasion are required.

Applications requiring high hardness, strength, and wear resistance frequently use stainless steel 440 bars. Common uses include manufacturing of cutting tools, surgical instruments, dies, molds, knife blades, and bearings. Pump shafts, valves, and other mechanical parts subjected to wear and friction are examples of industrial applications for SS 440 bars. They are also appropriate for precision-engineered components used in the aerospace and automotive industries. Because of its exceptional performance in dry or mildly corrosive conditions, SS 440 is a preferred material for tools and components that require durability and edge retention, even though it is not the best choice for highly corrosive environments.

©2024 Vinit Stainless All Rights Reserved.