Home > Electrodes > Alloy 309LMo SAW and Flux

Vinit Stainless is a Chennai, India-based leading producer and distributor of specialty stainless steel welding consumables. With immense emphasis on quality and accuracy, Vinit Stainless provides high-end products such as Alloy 309LMo SAW wire and matching flux for high-end industrial applications for welding. With its metallurgical expertise in stainless steel and advanced manufacturing techniques, the firm serves industries like petrochemical, power generation, offshore, and process piping. Vinit Stainless delivers customer satisfaction through technical assistance, guaranteed delivery, and products of international quality, such as ASME, AWS, and ISO standards for submerged arc welding applications.

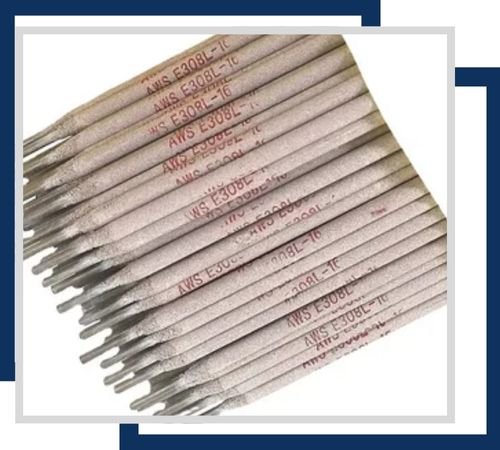

309LMo SAW wire is a stainless steel filler metal with about 23% Chromium, 13.5% Nickel, 2.5% Molybdenum, and minimal carbon content for improved resistance to corrosion. It is intended to provide better resistance to sulfurous-bearing atmospheres, oxidation, and high-temperature corrosion. Mechanical properties are usually tensile strength of about 550 MPa, yield strength of more than 350 MPa, and elongation of more than 30%. Together with suitable neutral or weakly basic fluxes, the duo provides superior slag detachability, clean bead appearance, and uniform weld metal quality, apt for welding dissimilar metals and high-temperature stainless steels.

| Classification | AWS A5.9, 309LMo |

| Form | Welding Fluxes and Wires |

| Type Of Welding | Submerged Arc Welding |

| Thickness available | Upto 4 mm |

| AWS 309LMo SAW & Flux Application & uses |

|

| C | Mn | Si | Cr | Ni | S | P | Mo | Cu |

| 0.03 max | 1.0-2.5 | 0.30-0.65 | 23-25 | 12-14 | 0.03 max | 0.03 max | 2-3 | 0.75 max |

| Tensile Strength | 89,900 |

|---|---|

| Yield Strength | 63,800 |

| Elongation (%) | 42% |

Contact us to get a quick quote for your requirement.

Alloy 309LMo SAW/Flux Welding Wire is used for submerged arc welding, providing high resistance to corrosion and oxidation, excellent weld strength, and a clean, slag-free finish for demanding applications.

Industrial 309LMo SAW Wire & Flux are used for submerged arc welding, offering high corrosion and oxidation resistance, strong welds, and a clean, slag-free finish, suitable for harsh industrial applications.

SFA A5.9 309LMo SAW & Flux are specified for submerged arc welding, providing superior corrosion and oxidation resistance, strong welds, and a clean, slag-free finish for demanding industrial environments.

Alloy 309LMo SAW wire paired with corresponding flux is employed for joining dissimilar metals, buffer layers, and high-temperature or corrosion-exposed stainless steels. Typical applications are petrochemical facilities, heat exchangers, furnace parts, marine parts, and desalination plants. It is especially designed to weld 300-series stainless steels to carbon steel or to overlay surfaces which are subject to chemical attack or thermal cycling. Its high metallurgical stability and weldability make it excellent for automated and mechanized welding processes. The introduction of molybdenum provides pitting and crevice corrosion resistance, thereby prolonging the service life of welded structures in hostile environments.

©2024 Vinit Stainless All Rights Reserved.