Home > Electrodes > AWS Class E309LMo-16 Electrodes

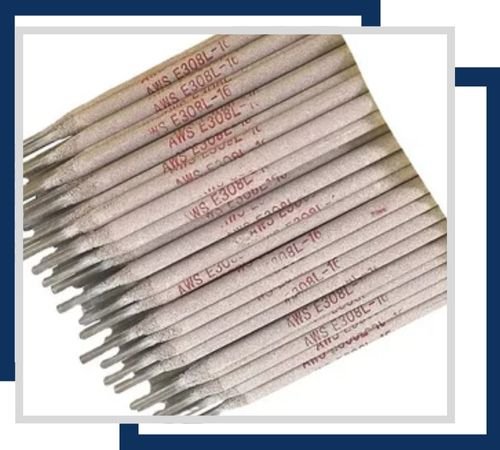

Vinit Stainless, located in Chennai, India, is a reliable manufacturer and supplier of AWS Class E309LMo-16 Electrodes, providing top-notch welding solutions for critical industrial needs. These stainless steel electrodes are expertly crafted for joining different metals and overlay welding, particularly in situations where outstanding corrosion and heat resistance are crucial. Renowned for their impressive arc stability, minimal spatter, and smooth bead finish, Vinit Stainless guarantees consistent quality that aligns with international standards. Our E309LMo-16 electrodes find extensive use in the fabrication of heat exchangers, pressure vessels, and chemical process equipment across the petrochemical, power, and marine sectors.

AWS Class E309LMo-16 Electrodes mainly consist of chromium (23–25%), nickel (12–14%), molybdenum (2–3%), and low carbon content (<0.04%). The inclusion of molybdenum boosts resistance to pitting and crevice corrosion, while the low carbon level helps prevent carbide precipitation. These electrodes deliver a tensile strength of about 580 MPa, a yield strength of around 480 MPa, and an elongation exceeding 30%. The weld metal exhibits excellent creep strength, oxidation resistance up to 850°C, and good toughness, even in sub-zero conditions. They are perfect for welding stainless to carbon steel and cladding in corrosive environments.

| Classification | AWS A5.4, E309/309L-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E309/309L-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.5-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer excellent resistance to oxidation and corrosion. They are available in 2.5 mm, 3.2 mm, and 4.0 mm diameters, designed for light-duty applications requiring minimal coating thickness.

These electrodes are known for superior corrosion resistance and are suitable for more demanding conditions. Sizes include 3.2 mm, 4.0 mm, and 5.0 mm, with a thicker coating that enhances durability and performance under heavy-duty usage.

These electrodes provide high resistance to corrosion and oxidation, featuring shielding to protect the weld from atmospheric contamination. Available in 2.5 mm, 3.2 mm, and 4.0 mm diameters, they are ideal for stable arc welding and consistent weld quality.

AWS E309LMo-16 Electrodes are applied in welding dissimilar metals and for buffer layers where there is a need for improved corrosion resistance. They find extensive use in chemical plants, desalination facilities, and offshore oil platforms where chloride-induced pitting resistance is of great importance. The electrodes are applicable in welding stainless steels to carbon or low-alloy steels and particularly in sulfuric acid or saltwater conditions. E309LMo-16 finds applications in heat exchangers, pressure vessels, and piping that need both corrosion resistance and structural strength. Molybdenum addition assures longer service life even under rigorous chemical and heat exposure.

©2024 Vinit Stainless All Rights Reserved.