Home > Electrodes > AWS Class E310-16 Electrodes

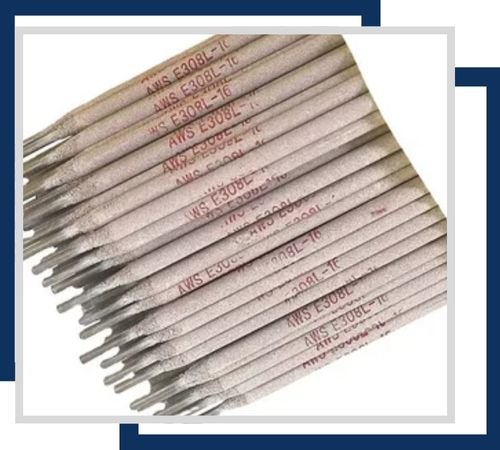

Vinit Stainless‘s AWS E310-16 electrodes are designed to weld extreme temperature and oxidation-resistant stainless steels. These high-alloy electrodes serve applications where thermal resistance, scale protection, and structural integrity at high temperatures are necessary. For stainless steels 310 and 310S, these electrodes provide good hot strength and oxidation resistance up to 1150°C. Featuring stable arc behavior and all-position weldability, they are appropriate for severe applications including furnaces, incinerators, and heat treatment systems. E310-16 provides reliability and long-term performance in high-temperature welding applications.

E310-16 electrodes have 25–28% Chromium and 20–22% Nickel content, which achieves a fully austenitic microstructure that resists oxidation and scaling at elevated temperatures. Weld metal provides tensile properties of around 580 MPa and exhibits very good creep resistance. The electrode ensures a smooth arc, controlled bead shape, and little slag, with all-position welding possible with both AC and DC currents. Its heat-resisting character makes it ideal for welding structures in high-temperature services. E310-16 does not lose ductility and toughness upon thermal cycling, providing structural integrity to weld joints subjected to constant exposure to heat.

| Classification | AWS A5.4, E310-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E310-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.08-0.20 | 25.0-28.0 | 20.0-22.5 | 0.75 | 1.0-2.5 | 0.75 | 0.03 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer exceptional corrosion resistance and are suitable for welding high-temperature alloys and stainless steels. They are available in sizes like 1/8″ and 5/32″ diameters, providing a balance of strength and ease of use.

With enhanced corrosion resistance, these electrodes are ideal for demanding welding applications involving high chromium stainless steels. They typically come in diameters of 3/16″ and 5/32″, offering robust performance and better deposition rates for thicker materials.

Known for their excellent corrosion resistance, these electrodes are designed for shielded arc welding of stainless steel and high-temperature alloys. Sizes include 1/8″ and 5/32″ diameters, providing strong welds and durability in harsh environments.

AWS E310-16 electrodes are suitable for welding parts subjected to high temperatures and oxidation, like those employed in furnaces, heat treatment facilities, kilns, and incinerators. They can be used most often in the fabrication of boiler tubes, radiant tubes, muffles, and exhaust stacks where heat resistance up to 1150°C is needed. They can also be utilized in joining stainless steel to carbon or low-alloy steels and in buffer layers to avoid dilution. Applications like power generation, petrochemical, cement, and metallurgy depend on E310-16 due to its resistance to thermal cycling, creep stress, and hostile combustion gases in high-temperature service conditions.

©2024 Vinit Stainless All Rights Reserved.