Home > Electrodes > AWS Class E316/316L-16 Electrodes

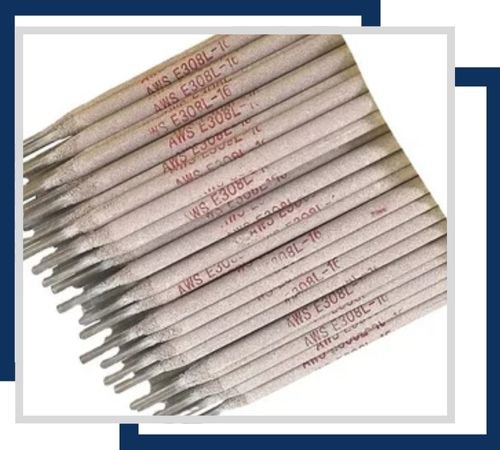

AWS E316/316L-16 electrodes are applied extensively in industries that seek high corrosion resistance and excellent weld soundness. Vinit Stainless manufactures these electrodes in Chennai and they are best suited for welding 316 and 316L austenitic stainless steels. The low carbon variant reduces the possibility of precipitation of carbide during welding, thereby ensuring corrosion resistance in the absence of post-weld heat treatment. These electrodes are best suited for sanitary and high-temperature uses in applications such as food processing, pharmaceutical, marine, and petroleum chemical industries. With stable arc behaviour and excellent slag removal, these provide consistent welding to critical structural and pressure-containing parts.

E316/316L-16 electrodes contain 18–20% Chromium, 11–14% Nickel, and 2–3% Molybdenum, and less than 0.04% carbon. Molybdenum addition provides enhanced resistance to pitting and crevice corrosion, particularly in chloride-containing environments. The electrodes produce weld metal with tensile strength of about 600 MPa and acceptable elongation and toughness. Low carbon content provides decreased risk of intergranular corrosion. Applicable to both AC and DC currents, these electrodes promote high arc stability and smooth bead formation. They permit all-position welding and are famous for minimum slag production and simple removal, even in multi-pass welds.

| Classification | AWS A5.4, E316/316L-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E316/316L-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.05 | 1.60 | 0.40 | 12 | 19 | 2.30 | 0.20 | 5.5 | FN |

Contact us to get a quick quote for your requirement.

Offering excellent corrosion resistance, these electrodes are available in sizes ranging from 3/32″ to 3/16″. They are ideal for welding thin sections of stainless steel, providing smooth arc stability and low spatter.

Designed for superior corrosion resistance, these heavy-coated electrodes come in sizes from 1/8″ to 3/16″. They ensure deep penetration and high deposition rates, making them suitable for thicker materials and high-stress applications.

These electrodes provide exceptional corrosion resistance and are available in sizes ranging from 1/16″ to 5/32″. They offer excellent shielding properties, ensuring minimal contamination and consistent weld quality suitable for various industrial applications.

E316/316L-16 electrodes are commonly applied for welding tanks, vessels, pipelines, and structural parts used in food, pharmaceutical, and chemical applications. They are best suited for applications involving exposed welds to chlorides and corrosive chemicals. The low carbon variant (316L) is especially applicable for welded joints that are not heat-treated after welding to provide long-term corrosion resistance. Used largely in the marine environment, water treatment facilities, and offshore platforms, they are also of vital importance in dairy equipment, cleanroom applications, and cosmetic processing units. Their weld cleanliness and reliability qualify them for hygienic, pressure vessel, and aesthetic fabrication applications.

©2024 Vinit Stainless All Rights Reserved.