The SMO 254 tubing possesses about 20% chromium, 18% nickel, 6% molybdenum, and nitrogen (0.18–0.22%), which gives an exceedingly high pitting resistance equivalent number (PREN >42.5). It possesses a tensile strength of ≥650 MPa and yield strength of ≥300 MPa, with elongation (~35%) being good. The addition of nitrogen adds strength and enhances localized corrosion resistance. SMO 254 tubes maintain their integrity in high-pressure–high-temperature applications. The synergy of mechanical performance and resistance to corrosion makes it one of the most trustworthy tubing materials for extreme and chloride-rich environments.

| ASTM Specification | ASTM A312/ASME SA312, ASTM A213/ ASME SA213 |

|---|---|

| Standard | EN, DIN, AISI, AMS, SAE, DTD, DS, NF, JIS, ASME, ASTM, GB, TOCT |

| Seamless Tube Size | 3.35 milimeter To 101.6 milimeter OD |

| Size of Seamless Pipe | Wall thickness.: 0.05- 20 milimeter, 4 – 219 milimeter |

| Size of Welded Pipe | 5.0 to 1219.02 milimeter |

| size of EFW Pipe | 5.0 to 1219.02 milimeter |

| Welded Tube Size | 6.35 milimeter To 152 milimeter OD |

| Bwg & Swg | 18 Swg., 14 20 Swg., Swg. Swg., 12 16 Swg., 10 Swg. |

| Value Added Service | Expansion and Draw as per needed Length and Size, , Polish (Comilimeterercial and Electro), Machining, Annealed & Pickled Bending Etc. |

| Pipe Schedule | STD, SCH120, SCH20, SCH10S, SCH30, SCH40, SCH140, SCH40S, SCH160, XS, SCH60, SCH5, SCH10, SCH80, XXS, SCH80 |

| Tubing wall thickness | 0.020″ –0.220″, (custom wall thicknesses available) |

| Finish | AP (Annealed & Pickled), BA (Bright & Annealed), NO.1, 2B, Polished, MF, HL, NO.4, Mirror finish, BA, 8K etc |

| End | Plain End, Beveled End, Treaded Pipe, Screwed ends |

| Length | Standard & Cut length , Single Random, Double Random Pipe |

| SMO 254 | C | Ni | Cr | Mn | Mo | Fe | Si | S | Cu | P |

| 0.002 maximum | 17.05 to 18.05 | 19.05 to 20.05 | 1 maximum | 6 to 6.05 | to | 0.08 maximum | 0.001 maximum | 0.05 to 1 | 0.003 maximum |

Contact us to get a quick quote for your requirement.

Vinit Stainless is a leading supplier, and stockist of high-quality stainless steel 254 tubing in Chennai, India. Our products are widely used in various applications, and we are committed to delivering excellent service, resulting in high customer satisfaction. Our unique finishing techniques further distinguish us in the stainless steel industry. We are dedicated to consistently providing superior products and effectively meeting our customer’s needs.

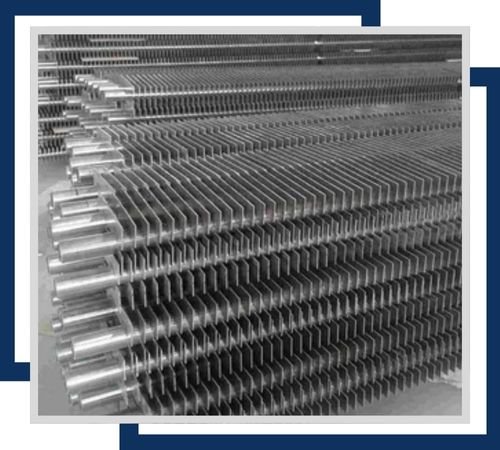

SMO 254 tubing is used in critical applications where applications are in chloride-rich and highly corrosive environments. Applications are common in heat exchangers, condensers, chemical process lines, marine fittings, offshore installations, and seawater systems for cooling. It is also found to be used extensively in flue gas desulfurization equipment, pulp and paper bleaching plant equipment, and desalination plants. Due to the good resistance against pitting and crevice corrosion, it can be used for carrying aggressive media under high pressure. Its fine weldability and toughness render SMO 254 tube the industry’s first choice in sectors that require long service life, low maintenance, and high corrosion resistance.

©2024 Vinit Stainless All Rights Reserved.