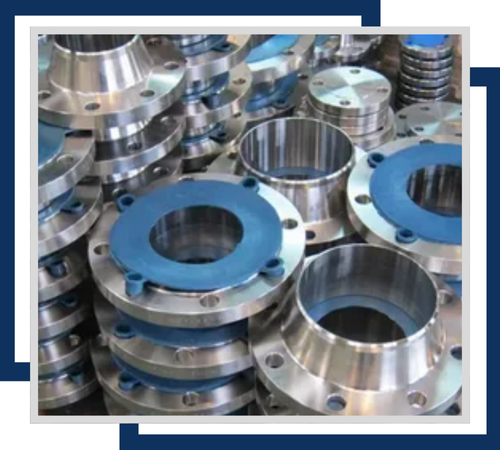

Premium-grade stainless steel 17-4 PH flanges made for high-performance industrial applications are available from Vinit Stainless, a well-known manufacturer and supplier with headquarters in Chennai, India. Even in challenging conditions, these precipitation-hardened stainless steel flanges are renowned for their exceptional strength, hardness, and resistance to corrosion. Vinit Stainless manufactures flanges that meet international standards, guaranteeing durability, dimensional accuracy, and peak performance under extreme pressure and stress. Vinit Stainless services important industries like aerospace, petrochemical, marine, and power generation in India and international markets with a strong dedication to quality, competitive pricing, and timely delivery.

About 15–17.5% chromium, 3–5% nickel, 3–5% copper, and trace amounts of niobium for improved precipitation hardening make up stainless steel 17-4 PH flanges. With a typical tensile strength of up to 1100 MPa and a yield strength of about 1000 MPa in the H900 heat-treated condition, these flanges demonstrate exceptional mechanical strength. Similar to Type 304, they provide good corrosion resistance and retain their strength and dimensional stability at high temperatures. Additionally, 17-4 PH flanges offer good weldability and are ideal for fabrication and machining in demanding applications.

| SS 17-4PH Flange Standard | ASTM A182 / ASME SA182 |

| SS 17-4 PH Flange Grade | SS 17-4PH / UNS S17400 / WERKSTOFF NR. 1.4542 |

| SS 17-4PH Flange Size Range | 1/2″ TO 48″ (15NB to 1200NB) Custom Sizes |

| SS 17-4 PH Flanges Class | Class 150, Class 900, Class 1200, Class 300, Class 600, Class 1500, Class 2500, / PN6, PN25, PN10, PN16, PN40, PN64, etc. |

| SS 17-4PH Flange Dimension | B16.48, B16.47 A & B, ASME/ANSI B16.5, BS4504, ASME Flanges, DIN Flanges, BS Flanges, ANSI Flanges, EN Flanges, BS 10, EN-1092, DIN, GOST Flange, ANSI/ASME B16.5, 16.47A, 16.47B, 16.36, MSS S44, API605, API7S-15, API7S-43, JISB2220, ISO70051, EN1092, BS1560-3.1, |

| SS 17-4 PH Flanges DIN | DIN 2576, DIN 2632, DIN 2637, DIN 2638, DIN 2636, DIN 2641, DIN 2527, DIN 2635, DIN 2655, DIN 2566, DIN 2629, DIN 2656, DIN 2573, DIN 2633, DIN 2642, DIN 2634, DIN 2631, DIN 2627, DIN 2673, DIN 2628 |

| Types of SS 17-4PH Flanges | Screwed (Threaded) Flanges, Spectacle Blind Flanges, Forged Flanges, Socket-weld Flanges (SWRF), Spacer & Blind Flanges, Ring Type Joint Flanges (RTJ), Plate Flanges, Slip-on Flanges (SORF), Blind Flanges (BLRF), Industrial Flanges, Flat Face Flanges, Raised Face (RF) Flanges, Custom Flanges, Orifice Flanges, Reducing Flanges, Large Diameter Flanges, Drawing Flanges, Lap Joint Flanges (SOLJ), Long weld neck Flanges (LWNRF), Weld neck Flanges (WNRF), etc. |

| Grade | Mn | Si | Cr | Ni | Fe | C | S | P | |

|---|---|---|---|---|---|---|---|---|---|

| 17-4 PH | min. | 1.0 | 1.0 | 15.0 | 3.0 | – | – | – | – |

| max. | 1.0 | 1.0 | 17.5 | 5.0 | 73 | 0.070 | 0.030 | 0.040 | |

| Properties | Metric | Imperial |

|---|---|---|

| Density | 7.75 g/cm3 | 0.280 lb/in3 |

Contact us to get a quick quote for your requirement.

Stainless Steel 17-4 PH reducing flanges are high-strength, corrosion-resistant components used to connect pipes of varying diameters. Ideal for demanding applications, they offer durability and reliability in harsh environments.

Stainless Steel 17-4 PH nipo flanges combine strength and corrosion resistance, ideal for high-pressure applications. They seamlessly connect pipes, providing a robust and reliable solution in demanding industrial settings.

Steel 17-4 PH ring-type joint flanges offer exceptional strength and corrosion resistance for high-pressure applications. Their precision design ensures a secure, leak-proof connection, making them ideal for demanding industrial environments.

DIN 1.4542 British Standard 17-4 PH pipe flanges combine high strength and corrosion resistance, meeting rigorous performance standards. They ensure reliable, leak-proof connections for demanding industrial applications.

Steel 17-4 PH forging facing flanges provide exceptional durability and strength for high-pressure applications. Designed for critical environments, they offer reliable performance with superior corrosion resistance and precise alignment.

ASME B16.5 SS 17-4 PH raised face flanges deliver high strength and corrosion resistance for demanding applications. Their raised face design ensures a secure, leak-proof seal, meeting stringent industry standards.

Applications requiring high strength, toughness, and corrosion resistance frequently use stainless steel 17-4 PH flanges. For connecting pipes, valves, and equipment under high pressure and temperature, industries like aerospace, oil and gas, chemical processing, food and beverage, power generation, and marine engineering depend on these flanges. Reactors, turbines, heat exchangers, and offshore platforms can all benefit from their superior mechanical qualities and resistance to pitting, crevice corrosion, and stress corrosion cracking. They are also perfect for critical structural and flow-control systems due to their long service life and dependable performance, which lower maintenance costs.

©2024 Vinit Stainless All Rights Reserved.