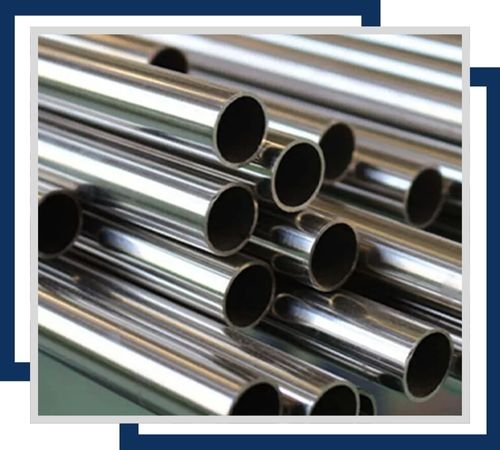

Based in Chennai, India, Vinit Stainless is a well-known stainless steel manufacturer and supplier that provides a large selection of premium stainless steel 201 pipes that are designed for performance, economy, and durability. In moderately aggressive environments, SS 201, a low-nickel austenitic stainless steel, provides exceptional mechanical strength and resistance to corrosion. To satisfy both domestic and international standards, our 201 pipes are made with precision manufacturing methods and stringent quality control procedures. Vinit Stainless provides affordable piping solutions without sacrificing strength or aesthetics to customers in a variety of industries, such as construction, decorative applications, transportation, and kitchen equipment.

The main constituents of stainless steel 201 pipes are manganese (5.5–7.5%) and chromium (16–18%), with a lower concentration of nickel (3.5–5.5%) and carbon (up to 0.15%). With a yield strength of about 275 MPa and elongation of about 40%, this composition produces good tensile strength (about 520–785 MPa). Excellent mechanical workability and reasonable corrosion resistance are guaranteed by the austenitic structure. SS 201 pipes are ideal for many non-critical structural and decorative applications where cost-effectiveness and moderate durability are important factors. They are not as corrosion-resistant as 304, but they have superior strength and formability.

| Standard Specification | 201 Stainless Steel Pipe |

| Surface Finish | Cold Finish, Polished, Annealing, Bright, Pickling |

| Schedule Pipe Thickness Range | SCH10, SCH XXS, SCH 40, SCH 160, SCH 80S, SCH 5, SCH 80, SCH XS Supplier in Mumbai |

| Types | ERW, Welded, Seamless, EFW |

| Sizes | ½ to 6 Inch |

| Manufacturing Technology | Hot / Cold Formed |

| Technique | Cold Rolled Hot Rolled |

| Wall Thickness | 0.1 To 60 mm |

| Manufacturing Shapes | Square, Round, Rectangle, Box Section |

| Standard | ASTM, GOST, ASME, DIN, EN, JIS, AMS, AISI, GB |

| Element | Content |

|---|---|

| Iron | 72 |

| Carbon | 0.15 |

| Chromium | 16.0 – 18.0 |

| Silicon | 1.0 |

| Manganese | 5.50 – 7.50 |

| Nickel | 3.50 – 5.50 |

| Nitrogen | 0.25 |

| Type | Tensile Strength | Yield Strength | Hardness Rockwell | Elongation |

|---|---|---|---|---|

| SS 201 ¾ Hard | 175 | 135 | 37 – 41 HRC (typical) | 12.0 |

| SS 201 ¼ Hard | 125 | 75 | 25 – 32 HRC (typical) | 25.0 |

| SS 201 Ann | 75 | 38 | HRB 95 max. | 40% |

| SS 201 ½ Hard | 150 | 110 | 32 – 37 HRC (typical) | 18.0 |

| SS 201 Full Hard | 185 | 145 | 41 – 46 HRC (typical) | 9.0 |

Contact us to get a quick quote for your requirement.

Stainless Steel 201 Seamless Pipe is a high-temperature alloy with excellent oxidation resistance, offering superior strength and durability in harsh environments. Ideal for aerospace and industrial applications

Stainless Steel 201 Welded Pipe provides excellent oxidation and corrosion resistance, suitable for high-temperature applications. Its welded construction offers cost efficiency and structural integrity in various industrial and aerospace uses.

Stainless Steel 201 ERW Pipe combines high-temperature resistance with exceptional durability. Its Electric Resistance Welded (ERW) construction ensures reliable performance in demanding environments, ideal for industrial and high-heat applications.

Stainless Steel TP 201 Seamless Pipes offer superior heat resistance and corrosion protection, ideal for high-temperature applications. Their seamless design ensures durability and reliability in industrial and aerospace environments.

Stainless Steel 201 Round Pipe features excellent heat resistance and corrosion resistance. Its round shape ensures versatility and strength, making it suitable for high-temperature industrial applications and structural uses.

Stainless Steel 201 EFW Pipe provides robust heat and corrosion resistance with Electric Fusion Welded construction. Ideal for high-temperature and industrial applications, it ensures durability and structural integrity.

Applications requiring high strength, formability, and aesthetics at a reduced cost frequently use stainless steel 201 pipes. Construction, automotive trim, railings, furniture frames, kitchen appliances, and food processing equipment are examples of common industries. In moderate indoor and outdoor settings, these pipes are perfect for decorative and structural uses like wall panels, exhaust systems, handrails, and tubing. SS 201 pipes are a convenient option for general-purpose projects needing reasonable corrosion resistance and durability, particularly when weight and cost reduction are crucial considerations. However, they are not advised for highly corrosive or marine environments.

©2024 Vinit Stainless All Rights Reserved.