With its headquarters located in Chennai, India, Vinit Stainless is a leading producer and supplier of stainless steel solutions. The business has established a solid reputation in a variety of industrial sectors thanks to its reputation for engineering precision and superior products. Stainless Steel 202 Tubing, one of its many products, is a high-performance, reasonably priced material that is renowned for its strength, resistance to corrosion, and adaptability. This tubing, which is made to international standards, is perfect for use in general manufacturing, automotive, and construction. Vinit Stainless continues to provide exceptional stainless steel products that surpass client expectations and endure harsh operating conditions by fusing innovation and dependability.

The austenitic chromium-nickel-manganese alloy known as stainless steel 202 tubing has roughly 17–19% chromium, 4–6% nickel, and 7–9% manganese. This composition is a cost-effective substitute for conventional 300-series stainless steels because it provides a good performance-to-cost ratio. High tensile strength, superior impact resistance, and good ductility are all displayed by SS 202. When annealed, it maintains its non-magnetic properties and exhibits robust resistance to corrosion and oxidation. It is also readily formable and weldable, which makes it a dependable option for a variety of structural and mechanical applications across multiple industries.

| Item | Stainless Steel 202 (Hot rolled, cold rolled) | |

| Thickness | 0.3~10.0mm | |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc | |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc | |

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc | |

| Surface | the surface and finish of stainless steel 202 sheet: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc | |

| Brand: | Indian Origin, European Origin, Japanese Origin, US Origin, Korea Origin, Thailand Origin, Taiwan Origin | |

| Manufacturer: | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, VDM, Nippon Metal, Outokumpu | |

| Package | Shrink-wrapped ,Carton boxes,Wooden pallets,Wooden boxes ,Wooden crates Etc. required. | |

| Export to | India, Indonesia, Malaysia, Singapore, Saudi Arabia, Qatar, India, Iran, Iraq, Oman, South Africa, Nigeria, Kenya, Italy, UK, Brazil, Russia , Egypt , Kuwait , Taiwan, Australia . |

|

Element |

Fe |

Cr |

Mn |

Ni |

Si |

N |

C |

P |

S |

|

|

Content (%) |

68 |

17-19 |

7.50-10 |

4-6 |

≤ 1 |

≤ 0.25 |

≤ 0.15 |

≤ 0.060 |

≤ 0.030 |

| Properties | Metric | Imperial | |

| Tensile strength | 515 MPa | 74694 psi | |

| Yield strength | 275 MPa | 39900 psi | |

| Elastic modulus | 207 GPa | 30000 ksi | |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 | |

| Elongation at break | 40% | 40% |

Contact us to get a quick quote for your requirement.

We ensures that all Stainless Steel 202 tubing is tested for quality and performance. Each batch is tested for tensile strength, corrosion resistance, and dimensional accuracy. CoC and test reports are provided, confirming adherence to industry standards and customer specifications.

With outstanding corrosion resistance, Stainless Steel 904L Seamless Tubing is ideal for high-pressure applications. Typically available in sizes ranging from 1/8″ to 8″ in diameter and custom lengths, it offers uniform strength and durability without weld seams.

Welded stainless steel tubing provides good corrosion resistance and is often used in less critical applications. Sizes generally range from 1/2″ to 12″ in diameter. Its manufacturing process involves welding a flat-rolled stainless steel sheet into a tube shape.

Stainless steel heat exchanger tubes are highly corrosion-resistant and designed for thermal conductivity. Available in various sizes, typically from 1/2″ to 4″ in diameter and up to 20 feet long. Essential for efficient heat transfer in industrial processes.

Instrumentation stainless steel tubing offers excellent corrosion resistance and is used for precise control systems. Standard sizes range from 1/16″ to 1″ in diameter. It ensures reliable performance in various high-pressure and high-temperature applications.

Boiler tubes of stainless steel are known for their exceptional corrosion and high-temperature resistance. Available in sizes from 1/2″ to 4″ in diameter. Designed for use in power generation and industrial boilers to handle high-pressure steam.

Stainless steel U-tubes provide high corrosion resistance and are used in heat exchangers and condensers. Sizes usually range from 1/2″ to 4″ in diameter. They are fabricated into a U shape to fit specific thermal or fluid flow requirements.

Condenser tubes made of stainless steel are highly corrosion-resistant and used in cooling systems. Commonly available in diameters from 1/2″ to 4″ and lengths up to 20 feet. Essential for efficient heat exchange in cooling applications.

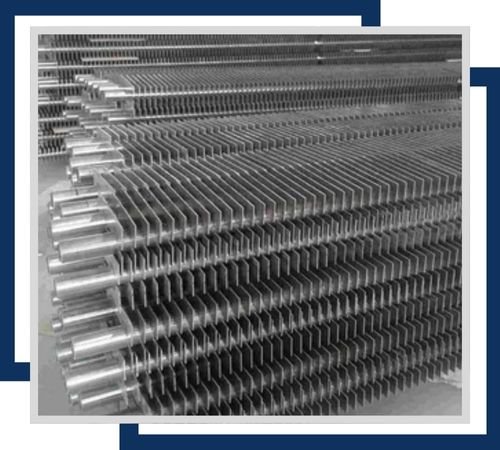

Stainless steel fin tubes offer enhanced heat transfer efficiency and corrosion resistance. Sizes range from 1/2″ to 4″ in diameter with various fin heights and thicknesses. They are used in applications with critical heat exchange efficiency, such as HVAC systems.

Because of its strength, resistance to corrosion, and affordability, stainless steel 202 tubing is extensively utilized in a variety of industries. Because of its strength and attractive finish, it is favored in architecture for railings, window frames, and structural frameworks. Because of its ease of maintenance and hygienic qualities, it is also utilized in kitchenware, food processing equipment, and utensils. 202 tubing is used in trim parts and structural components in the automotive industry. It is also appropriate for piping systems in the pharmaceutical and medical sectors, where cleanliness and non-reactivity are crucial, as well as in the transportation of fluids and gases. It is a popular option in many industrial sectors due to its versatility.

©2024 Vinit Stainless All Rights Reserved.