Based in Chennai, India, Vinit Stainless is a respectable producer and distributor of high-end stainless steel goods. We specialize in providing high-performance stainless steel solutions, such as Stainless Steel 253MA Tubing, and have a wealth of industry experience. This alloy is well-known for its remarkable strength and resistance to oxidation at high temperatures, making it perfect for harsh industrial settings. Vinit Stainless makes sure that our stainless steel tubing satisfies both domestic and international standards by placing a strong emphasis on precision engineering, product durability, and on-time delivery. We are a preferred partner for stainless steel solutions in India and beyond because of our technical know-how and customer-centric approach.

About 21% chromium, 11% nickel, 1.7% silicon, 0.09% nitrogen, and trace amounts of cerium make up the austenitic alloy known as stainless steel 253MA tubing. This alloy is designed to have exceptional strength at high temperatures, resistance to carburization, and resistance to oxidation. Under extended heat stress, it maintains structural integrity and exhibits a high creep rupture strength. The material offers a good balance of mechanical properties and thermal durability, and it is simple to fabricate and weld. Because of these characteristics, 253MA tubing is especially well-suited for harsh settings where sustained performance at high temperatures is crucial.

253 MA Pipe Specification : ASTM A312, A358 / ASME SA312, SA358

253 MA Tube Specification : ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

253 MA Pipe Size : 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

253 MA Tube Size : 1/2″ OD to 8″ OD.

Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type : Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish : 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing : Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials : Sizes and Specifications other than above can be manufactured on request

| Grade | C | Mn | Si | S | P | Fe | Ni | Cr | Ce | N |

|---|---|---|---|---|---|---|---|---|---|---|

| 253 MA | 0.10 max | 0.80 max | 2.0 max | 2.0 max | 0.04 max | Bal | 10.0 – 12.0 | 20.0 – 22.0 | 0.03 – 0.08 | 0.14 – 0.20 |

| Element | Density | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Hardness |

|---|---|---|---|---|---|

| 253 MA | 7.8 g/cm3 | 600 | 40 | 310 | HR B – 95, HB – 217 |

Contact us to get a quick quote for your requirement.

We ensures that all Stainless Steel 253MA Tubing undergoes rigorous testing for quality, performance and durability. Each product is thoroughly inspected, including chemical composition, mechanical properties and corrosion resistance. Certificates of compliance and test reports are issued to meet industry standards, ensure reliability and customer satisfaction.

Stainless Steel 253Ma Seamless Tubing is available in various sizes, including diameters from 1/8″ to 12″ and lengths up to 24 feet. This tubing offers exceptional corrosion resistance and strength at high temperatures. It is ideal for applications requiring robust performance in aggressive environments.

Stainless Steel 253Ma Seamless Tubing is available in various sizes, including diameters from 1/8″ to 12″ and lengths up to 24 feet. This tubing offers exceptional corrosion resistance and strength at high temperatures. It is ideal for applications requiring robust performance in aggressive environments.

Stainless Steel 253Ma Heat Exchanger Tubes are typically available in sizes from 1/2″ to 2″ in diameter. These tubes offer superior resistance to high temperatures and corrosive fluids, making them suitable for heat exchange applications in aggressive environments. Their durability ensures efficient heat transfer and long service life.

Stainless Steel 253Ma Instrumentation Tubing is available in diameters ranging from 1/8″ to 2″ and is known for its precision and durability. This tubing provides excellent resistance to oxidation and corrosion, making it ideal for use in instrumentation and control systems. Its stability ensures accurate measurements and reliable performance.

Stainless Steel 253Ma Boiler Tubes come in sizes from 1/2″ to 3″ in diameter and offer outstanding resistance to high temperatures and corrosion. They are specifically designed for use in boilers and other high-pressure applications, ensuring durability and longevity under extreme conditions

Stainless Steel 253Ma U-Tubes are available in various diameters, typically ranging from 1/2″ to 4″, and are used in applications requiring bent tubing. These tubes provide excellent resistance to heat and corrosion, making them ideal for heat exchangers and other systems involving high temperatures and corrosive substances.

Stainless Steel 253Ma Condenser Tubes are offered in sizes from 1/2″ to 2″ in diameter and are designed to withstand harsh conditions in condenser systems. They provide high resistance to corrosion and temperature fluctuations, ensuring effective performance and durability in thermal management systems.

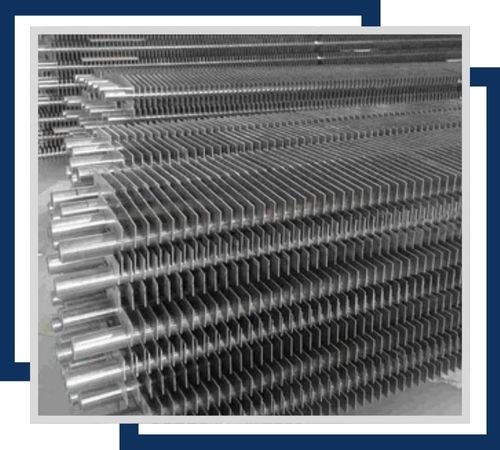

Stainless Steel 253Ma Fin Tubes are available with various fin heights and diameters, typically ranging from 1/2″ to 4″. These tubes are designed for enhanced heat transfer efficiency in finned tube heat exchangers. Their high resistance to corrosion and thermal stability makes them suitable for demanding applications.

253MA Stainless Steel Applications requiring high resistance to heat, oxidation, and carburization frequently use tubing. Common applications for the tubing include heat exchangers, furnace parts, combustion chambers, and gas turbines in the power generation, chemical processing, and aerospace industries. It is frequently used in kilns, exhaust systems, and thermal processing equipment and is perfect for petrochemical applications, such as refinery piping. Because of its strong composition, the alloy can endure harsh conditions, resulting in a longer service life and less maintenance. It is a material of choice for critical thermal operations due to its resistance to corrosion at high temperatures.

©2024 Vinit Stainless All Rights Reserved.