High-performance stainless steel 301L pipes for a variety of industrial applications are the speciality of Vinit Stainless, a top stainless steel manufacturer and supplier in Chennai, India. Low-carbon, high-strength austenitic stainless steel SS 301L is made for uses that call for good weldability, corrosion resistance, and formability. Modern machinery and quality control procedures that adhere to international standards are used by Vinit Stainless to manufacture 301L pipes. Our SS 301L pipes are extensively utilised in structural components, chemical processing, automotive, and aerospace applications where strength, durability, and light weight are critical. We are dedicated to providing dependable, long-lasting piping solutions that meet your requirements.

The main constituents of stainless steel 301L pipes are nickel (6–8%) and chromium (16–18%), with a lower carbon content (≤ 0.03%) to enhance sensitisation resistance and weldability. These pipes usually have an elongation of roughly 40%, a yield strength of about 205 MPa, and a tensile strength of roughly 520–680 MPa. The 301L grade is appropriate for forming and fabrication because it retains exceptional toughness and work hardening qualities. Its austenitic structure offers improved fatigue strength and mechanical durability in demanding industrial conditions, as well as good corrosion resistance, especially in mildly corrosive environments.

Specifications |

ASTM A240, ASME SA240 |

Dimensions |

ASTM, ASME and API |

Surface |

surface and finish of stainless steel sheets |

Type |

Ferritic Stainless Steel |

Processes |

Hot Rolled,Cold Rolled |

Thickness (mm) |

1.2~200 mm |

Width |

50~4020 mm |

Length |

50~18000 mm |

| Grade | C | Mn | Si | P | S | Cr | N | Ni |

| SS 301L | 0.03 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 16.0 – 18.0 | 0.10 max | 6.00 – 8.00 |

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 301L | 515 | 205 | 40 % |

Contact us to get a quick quote for your requirement.

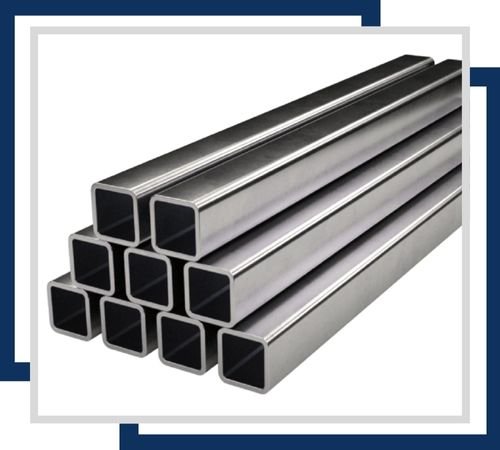

These pipes offer excellent corrosion resistance and are commonly used in structural applications. They come in various sizes, typically 20 mm to 100 mm in side length, with dimensions tailored to specific requirements.

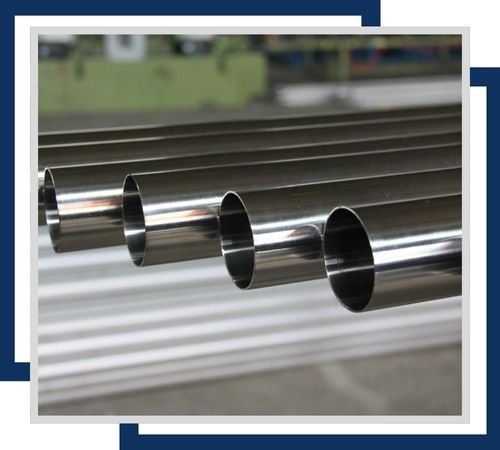

Featuring high corrosion resistance, these pipes are manufactured without weld seams. They are available in diameters ranging from 6 mm to 100 mm and lengths up to 12 meters, making them ideal for high-pressure and high-temperature applications.

Known for their corrosion resistance and cost-effectiveness, Electric Resistance Welded (ERW) pipes are produced in sizes from 15 mm to 300 mm in diameter. They are widely used in various industries due to their strength and precision.

These pipes provide excellent corrosion resistance and are fabricated using the Longitudinal Submerged Arc Welding process. They are available in diameters ranging from 100 mm to 1200 mm and are used for large-scale projects and pipelines.

Offering strong corrosion resistance, round pipes come in 6 mm to 300 mm diameters. They are commonly used in structural, automotive, and industrial applications due to their versatility and durability.

These pipes are known for their corrosion resistance and are produced by welding flat sheets. They are available in various sizes, from 15 mm to 200 mm in diameter, and are ideal for various applications.

Numerous applications requiring a blend of strength, ductility, and corrosion resistance use stainless steel 301L pipes. They are extensively used for trims, exhaust systems, and structural elements in the automotive and aerospace industries. They are dependable carriers of mildly corrosive fluids in the food processing and chemical industries. Because of its exceptional fabrication qualities and resistance to atmospheric corrosion, SS 301L is also perfect for welded assemblies, architectural structures, and transportation equipment. When lightweight material with high mechanical performance under moderate stress and environmental exposure is required, these pipes are especially advantageous.

©2024 Vinit Stainless All Rights Reserved.