Based in Chennai, India, Vinit Stainless is a leading producer and supplier of high-end stainless steel goods. The company, which specializes in providing high-performance stainless steel solutions, including Stainless Steel 304 Tubing, is well-known for its quality, accuracy, and dependability. One of the most widely used and adaptable stainless steel grades is SS 304 tubing, which is renowned for its remarkable mechanical strength, resistance to corrosion, and affordability. It is perfect for use in manufacturing, automotive, construction, and other fields. Vinit Stainless is dedicated to providing products that satisfy international standards, guaranteeing optimal client satisfaction and reliable performance in each and every application.

18–20% chromium, 8–10.5% nickel, and trace amounts of manganese, silicon, and carbon make up stainless steel 304 tubing. In a variety of settings, this austenitic alloy offers exceptional corrosion resistance. Tensile strength ranges from 515 to 827 MPa, yield strength is 205 MPa, elongation is 40% (in 50 mm), and hardness is approximately 201 HB. Superior weldability, formability, and impact resistance make SS 304 tubing perfect for use in sanitary and structural applications where durability, ease of fabrication, and hygiene are crucial.

Tube Range : 1/2″ OD – 12″ OD, Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 304 |

|---|---|

| Ni | 8 – 11 |

| Fe | Balance |

| Cr | 18 – 20 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.040 max |

| S | 0.030 max |

| N | – |

| Grade | 304 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | 201 |

Contact us to get a quick quote for your requirement.

We ensures high quality standards in the processing of Stainless Steel 304 Tubing through a rigorous testing and certification process. We ensure intensive inspection for dimensional accuracy, mechanical properties, corrosion resistance, and surface finish of our products. We can provide full traceability, including mill certificates, to ensure durability and performance compliance with international standards.

This tubing is available in a variety of sizes and diameters, typically ranging from 1/8″ to 12″ OD. It offers excellent corrosion resistance, particularly against oxidative and corrosive environments. Ideal for high-pressure applications due to its uniform strength and integrity.

Commonly found in sizes from 1/4″ to 8″ OD, this tubing is produced by welding a seam along its length. It provides good corrosion resistance and is often used in structural and decorative applications. Less uniform in strength compared to seamless tubing but cost-effective.

These tubes are designed for thermal exchange processes and come in sizes ranging from 1/2″ to 4″ OD. They offer superior resistance to heat and corrosion, making them ideal for use in various heating and cooling systems.

Typically available in sizes from 1/8″ to 2″ OD, this tubing is used for precision instrumentation. It features excellent resistance to corrosion and ensures accurate readings in a variety of monitoring and control applications.

Sized from 1″ to 6″ OD, these tubes are specifically designed for boiler systems. They provide high resistance to heat and corrosion, ensuring durability and reliability under high-pressure and high-temperature conditions.

These U-shaped tubes are often used in heat exchangers and come in sizes from 1/2″ to 3″ OD. They are highly resistant to corrosion and thermal stress, making them ideal for applications requiring efficient heat transfer.

: Available in sizes from 1/2″ to 3″ OD, these tubes are used in condenser systems. They provide excellent corrosion resistance and durability against the harsh conditions of cooling and condensation processes.

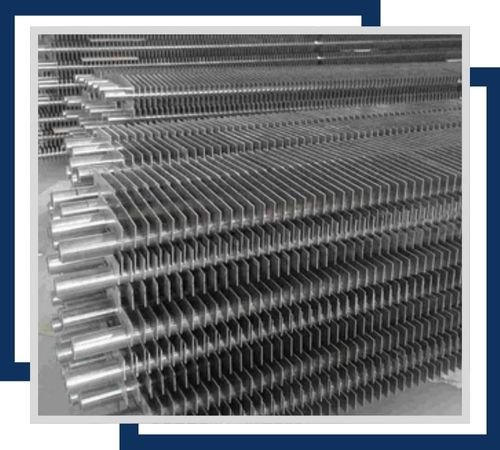

Typically found in sizes from 1″ to 4″ OD, fin tubes are used in heat exchangers and radiators. They offer strong corrosion resistance and enhanced heat transfer efficiency due to their finned surface design.

304 stainless steel Industries that need to be resistant to oxidation, corrosion, and chemical exposure use tubing extensively. Water treatment systems, chemical plants, pharmaceutical manufacturing, and food and beverage processing are examples of common applications. It is utilized in construction for structural frameworks, railings, and facades, and in the automotive industry for exhaust systems and engine components. The tubing is perfect for heat exchangers, HVAC systems, and medical devices because of its resistance to acids, chlorides, and high temperatures. It is appropriate for both indoor and outdoor settings due to its durability, hygienic finish, and low maintenance requirements.

©2024 Vinit Stainless All Rights Reserved.