Based in Chennai, India, Vinit Stainless is a well-known producer and supplier of high-end stainless steel goods. The business serves a broad spectrum of industrial applications and is renowned for providing solutions that are precise, long-lasting, and of excellent quality. Stainless Steel 310 Tubing, which is made to perform exceptionally well in corrosive and high-temperature conditions, is one of its best products. Vinit Stainless provides tubing solutions that satisfy global quality standards while being dedicated to excellence and client satisfaction. We continuously surpass client expectations across industries, both in India and globally, thanks to our emphasis on dependability, technical accuracy, and outstanding service.

Approximately 24–26% chromium and 19–22% nickel make up the austenitic alloy used to make stainless steel 310 tubing, which provides exceptional resistance to corrosion and oxidation at high temperatures. Up to 1100°C (2012°F), this tubing can tolerate constant service temperatures. It is perfect for applications subjected to heat stress because of its good creep resistance, yield strength of 205 MPa, and tensile strength of about 515 MPa. The alloy is a dependable material for extended use in challenging, high-temperature conditions because it retains structural integrity and resists scaling.

Specifications : ASTM A213 / ASME SA213

Outside Diameter : 1/8″ OD TO 2″OD 3MM OD TO 38 MM OD

Thickness : 1MM TO 3 MM 0.028 TO 0.156 IN, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Size : 1/2″ NB – 24″ NB

Type : Seamless / Capillary Tubes

Form : Round Tubes, Square Tubes, Rectangular Tubes.

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

Finish : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 40 % |

Contact us to get a quick quote for your requirement.

We ensures the highest quality stainless steel 310 tubing through rigorous testing including mechanical, chemical and theoretical analysis. The tubing is certified by industry standard tests such as PMI, hardness and tensile strength. Each batch is issued with appropriate certifications, ensuring compliance with international quality and safety standards.

Seamless tubing in Stainless Steel 310 offers excellent corrosion resistance in temperatures up to 1150°C. Available in sizes from 1/8” to 8” in outer diameter, it is ideal for high-temperature applications requiring strength and durability. Its seamless construction ensures a smooth surface finish and uniformity.

Welded tubing in Stainless Steel 310 provides robust corrosion resistance and is designed for high-temperature environments up to 1100°C. Sizes range from 1/8” to 24” in outer diameter, with wall thicknesses that can be customized. The welded seams are meticulously inspected to ensure leak-proof performance.

Heat exchanger tubes made from Stainless Steel 310 are known for their high resistance to oxidation and corrosion in cyclic environments up to 1050°C. Available in sizes from 1/8” to 2” outer diameter, these tubes ensure efficient heat transfer in both industrial and commercial applications. They maintain structural integrity under fluctuating thermal conditions.

Heat exchanger tubes made from Stainless Steel 310 are known for their high resistance to oxidation and corrosion in cyclic environments up to 1050°C. Available in sizes from 1/8” to 2” outer diameter, these tubes ensure efficient heat transfer in both industrial and commercial applications. They maintain structural integrity under fluctuating thermal conditions.

Boiler tubes made from Stainless Steel 310 exhibit excellent corrosion resistance in environments up to 1100°C. Available in sizes from 1/8” to 5” outer diameter, these tubes are designed to withstand high pressures and temperatures in steam boiler applications. Their durability ensures long service life and operational efficiency.

U-Tubes in Stainless Steel 310 are designed for use in heat exchangers and condensers, offering high corrosion resistance up to 1050°C. Sizes range from 1/4” to 2” in outer diameter, with custom bend radii to fit specific applications. Their U-shape allows for efficient thermal expansion and contraction

Condenser tubes made of Stainless Steel 310 provide excellent corrosion resistance in temperatures up to 1050°C. Sizes typically range from 1/8” to 2” in outer diameter, ensuring effective heat exchange in condensers and cooling systems. Their resistance to thermal fatigue makes them suitable for continuous operation.

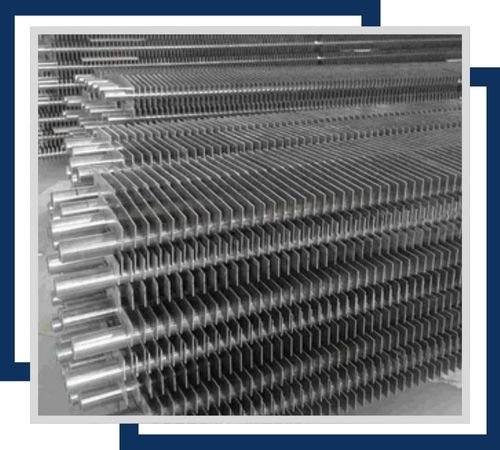

Fin tubes in Stainless Steel 310 are known for their exceptional corrosion resistance and thermal conductivity at temperatures up to 1050°C. Sizes vary based on fin and tube dimensions, commonly ranging from 1/4” to 1” in outer diameter. The finned design enhances heat transfer efficiency in air-cooled and heat recovery applications.

Many industries that require exceptional resistance to heat and corrosion use stainless steel 310 tubing. It is especially useful in the electrical, power generation, chemical processing, and aerospace industries. Heat exchangers, furnace parts, boiler tubes, air filters, and kiln linings are common uses where strong structural stability and high thermal resistance are crucial. It is perfect for high-temperature equipment and corrosive gas environments because of its resistance to scaling and ability to retain mechanical strength at high temperatures. Because of its extended service life, this tubing is the recommended option for parts that are exposed to high temperatures and mechanical strain.

©2024 Vinit Stainless All Rights Reserved.