Based in Chennai, India, Vinit Stainless is a well-known producer and supplier of premium stainless steel goods. The business is well-known for providing high-end stainless steel solutions and specializes in a variety of industrial goods, such as Stainless Steel 310H Tubing. SS 310H tubing is extensively utilized in the petrochemical, power generation, and chemical processing industries due to its remarkable durability, corrosion resistance, and heat resistance. In order to provide precision-engineered products that satisfy international quality standards for demanding industrial environments, Vinit Stainless is dedicated to providing affordable, globally compliant solutions.

Austenitic stainless steel alloy 310H, which is intended for high-temperature use, has about 25% chromium and 20% nickel. To improve its resistance to oxidation and corrosion, the alloy also contains trace amounts of silicon, manganese, and carbon. With a yield strength of 205 MPa, high tensile strength (approximately 515 MPa), and good ductility, SS 310H maintains its mechanical integrity even at high temperatures. It is perfect for crucial heat-intensive applications like industrial furnaces and thermal processing equipment because of its exceptional resistance to creep, thermal fatigue, and scaling.

| 310H Stainless Steel Tube Finish | Polished, BA (Bright & Annealed),AP (Annealed & Pickled), MF |

|---|---|

| Stainless Steel 310H Tube Standards | ASTM A213,ASTM A269, ASTM A249,ASME SA213,ASME SA269, ASME SA249, NACE MR0175/ISO 15156, PED 97/23/EC,EN 10216-5 TC1 / TC2, AD 2000 |

| Stainless Steel 310H Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| 310H stainless steel tubing End | Plain End, Beveled End, Treaded, Ends are suitable for orbital welding |

| Marking | All 310H Stainless Steel tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Stainless Steel 310H Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Stainless Steel 310H tubing wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Stainless Steel 310H tube Form | Straight or ‘U’ bent Tubes, Round,Boiler, Coil , LSAW Tubes, Square, Hydraulic, Rectangular, Hollow Etc. |

| Stainless Steel 310H Tube Type | EFW, Seamless , Fabricated, ERW, Welded |

| SS 310H tube Length | Single Random , Standard & Cut length , Double Random |

| Non-Electropolished | (CFOS) Cleaned for Oxygen Grade Service or Corrosive Systems, (BA) Bright Annealed or (AP) Annealed & Pickled for High-Purity |

| I.D. Surface Finish Options | 5, 7 & 10 µin. Ra |

| 310H stainless steel tubing Testing & Inspection | Visual inspection • Surface roughness measurement • Helium-leak testing • Scanning Electron Microscopy (SEM) • Auger Electron Microscopy (AES) • Election Spectroscopy for Chemical Analysis (ESCA or XPS) • Particle testing • Moisture testing |

| Tolerances | In accordance with: ASTM: A269 & A632, JIS: G 3459 |

| 310H stainless steel tubing Test Certificate | Laboratory Test Certificate from Govt. Approved Lab. Manufacturer Test Certificate according to EN 10204 3.1 B Under Third Party Inspection |

| Electropolished | (EP) Electropolished for Ultra High Purity Systems |

| 310H stainless steel tubingApplication | Oil Tube , Boiler and Heatexchange , Gas Tube, Fluid Tuber |

| JIS | 8A to 250A |

| Specialize in | Stainless Steel 310H Capillary Tube & Other Odd Size Stainless Steel 310H Hydraulic tubing with OD up to 50.8 mm (2.0 in.) are delivered in bright annealed condition Stainless Steel 310H Heat Exchanger & Condenser Tubes Stainless Steel 310H hydraulic tube with OD larger than 50.8 mm are supplied in the annealed and pickled condition, Or in polished condition |

| Marking & Traceability | Each Stainless Steel 310H Tubing is traceable to its producing mill and heat by an identification number etched within 24″ (610mm) of one end. |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 310H | min. | 0.04 | – | – | – | – | 24.0 | – | 19.0 | – |

| max. | 0.10 | 2.0 | 1.0 | 0.045 | 0.030 | 26.0 | 21.0 | – | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 310H | 515 | 205 | 40 | 95 | 217 |

Contact us to get a quick quote for your requirement.

We ensures that all stainless steel 310H tubing is rigorously tested to meet international quality standards, including mechanical, chemical and thickness analysis. Relevant certifications, such as Mill Test Certificates (MTC), EN 10204-3.1, and third party inspection reports are included with each tube, to ensure efficiency and reliability

Stainless Steel 310H Seamless Tubing is available in sizes ranging from 1/8″ to 24″ in diameter. This type of tubing offers exceptional corrosion resistance, especially in high-temperature environments. Its seamless construction ensures uniform strength and reliability.

Stainless Steel 310H Welded Tubing comes in sizes from 1/8″ to 48″ in diameter, providing excellent corrosion resistance. The welded construction allows for cost-effective production while maintaining high strength and durability. It is suitable for applications requiring precise dimensions.

Stainless Steel 310H Heat Exchanger Tubes are designed with sizes ranging from 1/4″ to 2″ in diameter. These tubes offer superior corrosion resistance and thermal conductivity, making them ideal for heat exchanger applications. They perform well in high-temperature and high-pressure environments.

Stainless Steel 310H Instrumentation Tubing is available in sizes from 1/8″ to 1″ in diameter. It provides excellent corrosion resistance and is used in precise instrumentation and control systems. The tubing ensures consistent performance in critical environments.

Stainless Steel 310H Boiler Tubes come in sizes ranging from 1/2″ to 5″ in diameter. They offer high corrosion resistance and are designed to withstand high pressures and temperatures in boiler applications. The tubes ensure efficient heat transfer and long-term durability.

Stainless Steel 310H U-Tubes are available in diameters from 1/4″ to 2″. These tubes provide excellent corrosion resistance and are shaped into U-bends for use in heat exchangers. They are ideal for compact heat exchanger designs and efficient thermal transfer.

Stainless Steel 310H Condenser Tubes range from 1/4″ to 2″ in diameter, offering superior corrosion resistance. These tubes are used in condenser systems to efficiently transfer heat. They perform well in both high-temperature and corrosive environments.

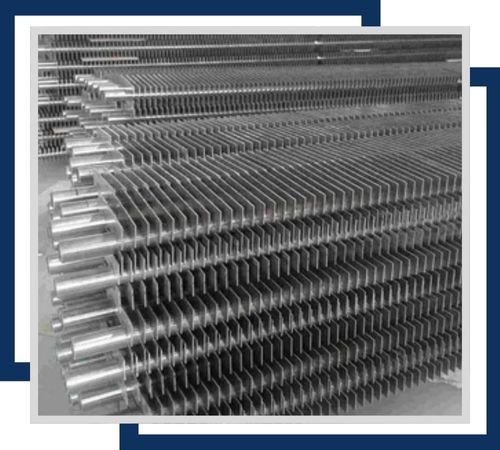

Stainless Steel 310H Fin Tubes come in sizes from 1/4″ to 2″ in diameter. They are designed with fins to enhance heat transfer efficiency and provide excellent corrosion resistance. These tubes are ideal for use in air-cooled heat exchangers and other thermal systems.

In high-temperature applications where mechanical strength and resistance to oxidation are crucial, stainless steel 310H tubing is frequently used. It is widely utilized in boilers, heat exchangers, furnace components, and thermal processing equipment in a variety of industries, including petrochemicals, power generation, chemical processing, and aerospace. The alloy is perfect for demanding operating conditions because it can withstand scaling and deformation up to 1100°C (2012°F). Its high concentration of nickel and chromium guarantees superior resistance to thermal expansion, creep, and corrosion, ensuring long-term durability in demanding and corrosive industrial environments.

©2024 Vinit Stainless All Rights Reserved.