Based in Chennai, India, Vinit Stainless is a reputable producer and supplier of stainless steel 310S tubing. Vinit Stainless is renowned for their proficiency in high-temperature stainless steel solutions and provides precisely engineered 310S tubing that is perfect for use in corrosive and heat-intensive environments. Their 310S tubing satisfies international quality standards and performance specifications because it is made with premium-grade raw materials and state-of-the-art technology. Vinit Stainless is a dependable option for crucial stainless steel tubing requirements worldwide because of their emphasis on longevity, prompt delivery, and customer satisfaction. They serve a wide range of industries, including petrochemical, power generation, and thermal processing.

With a lower carbon content for better weldability and corrosion resistance, stainless steel 310S tubing is an austenitic chromium-nickel alloy with about 25% chromium and 20% nickel. Up to 1100°C, it provides exceptional oxidation resistance and high-temperature strength. Mechanical characteristics include a yield strength of about 205 MPa and a tensile strength of about 520 MPa. Even at high temperatures, the alloy retains its good toughness and ductility. Additionally, 310S has exceptional resistance to thermal fatigue and sulfidation, which makes it perfect for furnace and heat treatment applications where a long service life is essential.

| Specifications | ASTM A/ASME SA213/A249/A269/A312/A358 CL. I to V ASTM A789/A790 |

| Size | Seamless 310S Pipes and Tubes – 1/2″ NB – 16″ NB |

| ERW 310S Pipes and Tubes | 1/2″ NB – 24″ NB |

| EFW 310S Pipes and Tubes | 6″ NB – 100″ NB |

| Wall Thickness | Schedule 5S – Schedule XXS. |

| Dimensions | ASTM, ASME and API |

| Schedule | SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Length | Single Random, Double Random & Cut Length. |

| Form | Round, Square, Rectangular, Hydraulic Etc. |

| Element | SS 310S |

|---|---|

| Ni | 14 max |

| Cr | 23 max |

| C | 0.20 max |

| Fe | 60 max |

| Mn | 2 max |

| Si | 1 max |

| S | 0.030 max |

| P | 0.045 max |

| Element | SS 310S |

|---|---|

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 45000 , MPa – 205 |

| Elongation | 45 % |

Contact us to get a quick quote for your requirement.

Stainless Steel 310s Seamless Tubing, known for its excellent corrosion resistance, typically comes in sizes ranging from 1/8″ to 24″ in diameter. This tubing is ideal for high-temperature applications and provides a smooth, continuous surface without any welds.

Stainless Steel 310s Welded Tubing offers good corrosion resistance and is available in sizes from 1/8″ to 36″ in diameter. It is manufactured by welding strips of stainless steel and is suitable for both structural and fluid transport applications.

Stainless Steel 310s Heat Exchanger Tube, resistant to oxidation and corrosion, typically ranges from 1/4″ to 3″ in diameter. It is designed for high-temperature service in heat exchangers, ensuring efficient thermal transfer.

Stainless Steel 310s Instrumentation Tubing, with high corrosion resistance, comes in sizes from 1/8″ to 1″ in diameter. It is used in precise instrumentation applications, providing accurate and reliable measurements.

Stainless Steel 310s Boiler Tubes, known for their excellent corrosion resistance, are available in sizes from 1/8″ to 5″ in diameter. These tubes are used in boiler systems, offering high-temperature performance and durability.

Stainless Steel 310s U-Tubes, offering good corrosion resistance, typically range in sizes from 1/4″ to 2″ in diameter. These tubes are bent into U shapes for heat exchangers and other applications where compact design is essential.

Stainless Steel 310s Condenser Tube, resistant to corrosion and high temperatures, comes in sizes from 1/8″ to 2″ in diameter. It is used in condensers to efficiently condense steam and other vapors back into liquid form.

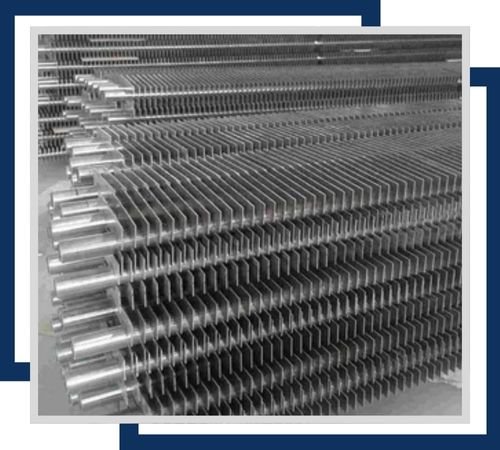

Stainless Steel 310s Fin Tubes, with high corrosion resistance, are available in sizes from 1/4″ to 1″ in diameter. These tubes have fins attached to their surface to enhance heat transfer efficiency in heat exchangers.

Because of its remarkable mechanical strength and heat resistance, stainless steel 310S tubing is frequently used in corrosive and high-temperature environments. It is frequently used in combustion chambers, kilns, heat exchangers, and furnace components. Additionally, the tubing is perfect for thermal oxidisers, power plants, and petrochemical processing. It is appropriate for use in refinery equipment, steam boilers, and flue gas ducting due to its resistance to oxidation and scaling at high temperatures. The use of 310S tubing in high-cleanliness applications that demand corrosion protection and heat resistance in the food and pharmaceutical industries ensures longevity, performance, and safety in crucial processes.

©2024 Vinit Stainless All Rights Reserved.