Home > Stainless Steel 316/316L Channels

Vinit Stainless is a leading manufacturer and supplier of SS 316 valves in Chennai, India. Our SS 316 valves are manufactured with high-quality stainless steel and modern technology to deliver competent flow control solutions. SS 316 grade valves possess superior heat and corrosion resistance, particularly in chloride environments due to its superior corrosion properties. We at Vinit Stainless provide different configurations such as ball valves, gate valves, and globe valves to meet industrial, marine, and chemical processing requirements. Our products are created with the intention to provide safe, leak-free performance and resist high pressure and temperature.

SS 316 valves consist of 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, providing greater corrosion resistance than SS 304. They possess tensile strength of approximately 515 MPa and yield strength of 205 MPa. SS 316 retains excellent ductility and toughness at high temperatures and offers superior pitting and crevice corrosion resistance, which makes SS 316 valves appropriate for high-performance, corrosive use.

| Standard | ASTM A276, ASTM A479 / ASME SA276, ASME SA479 |

| Condition | HRAP |

| Size Range | Base: 80 to 150 mm Side: 40 to 75 mm |

| Thickness | 5 to 6 mm (depending on size) |

| Grades | 304, 316 |

| Processing | Bar cutting |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 |

| SS 316 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 1.0 max | 16.00 – 18.00 | 16.00 – 18.00 | 10.00 – 14.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

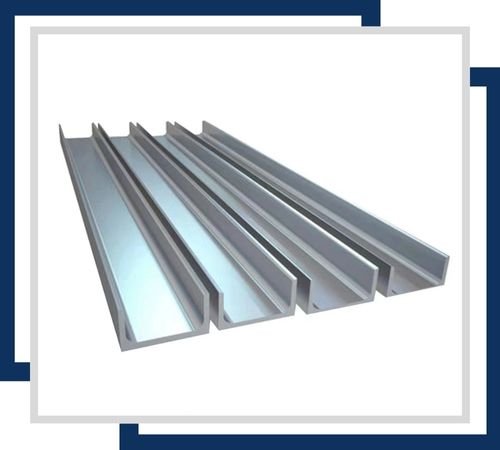

Stainless Steel 316/316L channels are structural elements made from corrosion-resistant stainless steel. They provide high strength and durability, ideal for marine, chemical, and high-temperature applications.

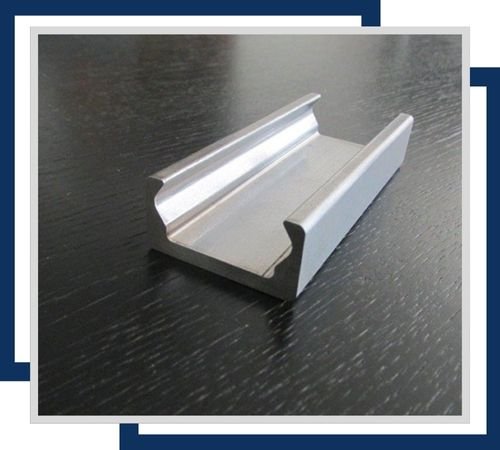

SS 316/316L C channels are stainless steel sections shaped like a “C,” offering high strength and superior corrosion resistance. They are used for support and framing in demanding environments.

Stainless Steel 316/316L U channels are structural components with a “U” shape, known for excellent strength and corrosion resistance. They are used in marine, chemical, and high-temperature environments for support and reinforcement.

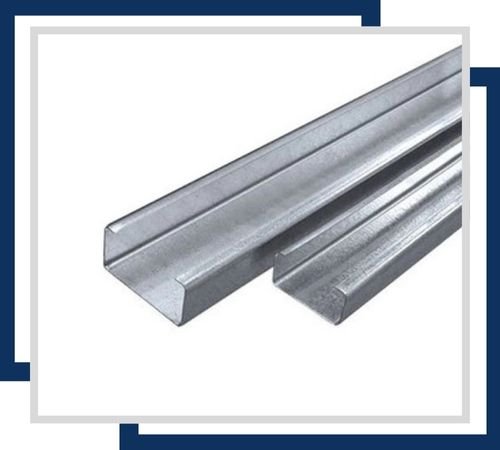

SS 316/316L strut C channels are stainless steel sections with a “C” shape, designed for robust support and framing. They offer high strength, durability, and excellent corrosion resistance for industrial applications.

SS 316/316L cold-rolled Unistrut channels are stainless steel channels produced through cold rolling. They offer high strength, excellent corrosion resistance, and are used for versatile support and framing in demanding environments.

SS 316/316L double C type channels are stainless steel sections with two “C” shapes back-to-back. They provide enhanced strength and stability, suitable for heavy-duty support and structural applications in harsh environments.

SS 316 valves find extensive applications in chemical plants, marine operations, food processing facilities, and pharmaceutical industries. The valves’ corrosion resistance even in saltwater and acidic environments makes them perfect for offshore and coastal operations. The valves play a vital role in precision flow control systems, cleanliness requirements, and toughness. Vinit Stainless makes sure that every valve goes through stringent testing and certification for safety and reliability in harsh industrial operations.

©2024 Vinit Stainless All Rights Reserved.