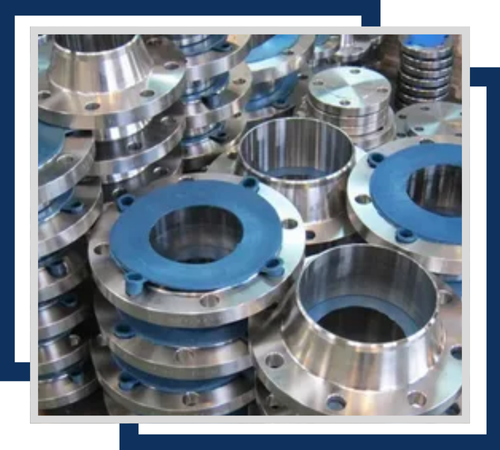

SS 316 flanges are austenitic stainless steel flanges used for their remarkable resistance to corrosion and high temperature. Made and supplied by Vinit Stainless in Chennai, India, they provide robust performance in severe industrial conditions. Addition of molybdenum is responsible for their anti-chloride as well as acidic corrosion resistance, which makes them appropriate for stringent service conditions. The flanges are extensively being utilized in chemical, petrochemical, marine, and food industries because of their toughness and suitability to other media. Vinit Stainless takes utmost care that the quality of every flange is international standard, providing long-lasting, reliable, and accurate flange solutions to various industry sectors.

SS 316 flanges are usually made up of 16–18% Chromium, 10–14% Nickel, 2–3% Molybdenum, and up to 0.08% Carbon. The molybdenum improves corrosion resistance, particularly against chlorides. They have a tensile strength of approximately 515 MPa and yield strength of 205 MPa. They also show great toughness at sub-zero temperatures. SS 316 flanges sustain structural integrity at thermal stress and mechanical load. Their mechanical resilience and balanced chemical composition render them a widely used general-purpose material for industrial applications as well as high-demand uses.

| Specifications | ASTM A182 / ASME SA182 |

| Size | 1/8″ NB TO 48″ NB |

| Standards | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grades | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| SS | 316 |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 95 |

| Brinell (HB) max | 217 |

Contact us to get a quick quote for your requirement.

SS 316 Slip-On Flanges are easy to install and typically used in low-pressure applications. They are available in a wide range of sizes from 1/2″ to 24″ in diameter. Made from stainless steel 316, they offer excellent corrosion resistance, making them ideal for marine and industrial environments.

Stainless Steel 316 Weld Neck Flanges feature a long tapered hub, which provides added strength and reduces stress at the base of the flange. These flanges range in sizes from 1/2″ to 48″ and are designed for high-pressure systems. The stainless 316 composition ensures high corrosion resistance and durability.

SS 316 Blind Flanges are used to seal the ends of piping systems or pressure vessel openings. Available in sizes from 1/2″ to 60″, these flanges can withstand high-pressure environments. Their stainless steel 316 material offers superior resistance to corrosion, making them suitable for harsh conditions.

Stainless 316 Steel Threaded Flanges are designed for systems that require quick assembly and disassembly. They come in sizes ranging from 1/2″ to 24″. The 316 stainless steel construction provides excellent corrosion resistance, ideal for plumbing and water treatment applications.

SS 316 Socket Weld Flanges are stainless steel fittings that allow pipes to be inserted into a recessed area before welding. They provide strong, leak-proof connections for small-diameter, high-pressure applications.

Stainless 316 Steel Lap Joint Flanges are used with stub end fittings and are suitable for systems requiring frequent dismantling. These flanges range in sizes from 1/2″ to 24″. The 316 stainless steel provides exceptional corrosion resistance, making them ideal for use in corrosive environments

SS 316 flanges find application in various industries due to their resistance to corrosion, oxidation, and heat. Some common uses are chemical transport lines, marine equipment, oil and gas pipes, and food-grade processing facilities. They find applications in heat exchangers, reactors, and boiler systems because they are strong and resistant to corrosive media. SS 316 flanges find application in coastal structures and shipbuilding where exposure is high to chlorides. Their strength, non-reactive surface, and clean finish make them a leading choice in sanitary applications, providing reliability, safety, and long-term performance in industrial and marine applications.

©2024 Vinit Stainless All Rights Reserved.