SS 316 tubing is high-performance austenitic stainless steel tube with superior corrosion resistance and strength in harsh environments. Produced and supplied by Vinit Stainless in Chennai, India, these tubes are best suited for critical processes with exposure to chemicals, seawater, and acid media. SS 316 tubing finds extensive applications in chemical processing, food and beverage, pharmaceutical, and marine engineering industries. With a smooth interior surface, higher strength, and weldability, Vinit Stainless supplies SS 316 tubing in a range of sizes and finishes to international standard as well as customer-specific requirements for structural and high-purity applications.

SS 316 tubing consists of 16–18% Chromium, 10–14% Nickel, and 2–3% Molybdenum, with a carbon limit up to 0.08%. The molybdenum enhances resistance to crevice corrosion and pitting in environments containing chloride. These tubes possess a tensile strength of approximately 515 MPa and a yield strength of 205 MPa, with excellent elongation and hardness. SS 316 exhibits excellent strength at high temperatures and also toughness at sub-zero temperatures. It possesses great formability, weldability, and corrosion resistance, and thus is well suited for applications in aggressive or hygienic conditions.

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubing

| SS | 316 |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 95 |

| Brinell (HB) max | 217 |

Contact us to get a quick quote for your requirement.

This tubing is available in sizes ranging from 1/8″ to 12″ in diameter and is known for its excellent corrosion resistance, particularly in marine and chemical environments. The seamless construction ensures high strength and reliability.

Typically offered in sizes from 1/4″ to 8″ in diameter, this tubing is fabricated by welding stainless steel sheets. It provides good corrosion resistance, making it suitable for structural applications and chemical processing.

Designed for heat exchange applications, this tubing generally comes in sizes from 1/2″ to 2″ in diameter. It boasts superior corrosion resistance and thermal conductivity, ideal for use in heat exchangers and condensers.

Available in sizes from 1/16″ to 1″ in diameter, this tubing is used in high-pressure and precision applications. It offers excellent resistance to corrosion and is ideal for instrumentation and process control systems.

Typically found in sizes from 1″ to 5″ in diameter, these tubes are designed for high-temperature and high-pressure environments. They provide strong corrosion resistance and durability for boiler systems.

Used in heat exchangers and other applications requiring a U-shaped tube, sizes range from 1/2″ to 4″ in diameter. They offer high resistance to corrosion and are designed for effective thermal performance.

This type comes in sizes from 1/2″ to 2″ in diameter and is used in condensers for its excellent corrosion resistance and durability in cooling applications. Ideal for heat transfer and cooling systems.

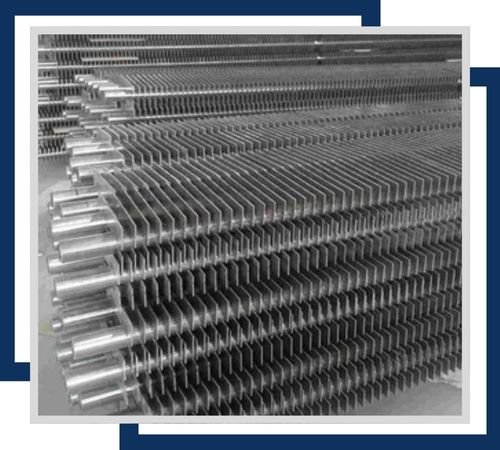

Typically available in diameters from 1/2″ to 2″, these tubes have fins attached to enhance heat transfer efficiency. They are highly resistant to corrosion and are used in heat exchangers and other cooling systems.

SS 316 tubing finds extensive application in high corrosion, hygiene, and structural integrity demanding industries. It is extensively used in chemical and petrochemical plants, marine applications, pharmaceutical manufacturing lines, and food and beverage processing lines. The tubing is also employed in heat exchangers, instrumentation lines, fluid transportation systems, and desalination plants. Its superior resistance to chlorides and corrosive environments makes it fit for coastal and offshore installations. SS 316 tubing is the choice in situations where cleanliness, contamination resistance, and mechanical strength are of significance, offering long-term durability and dependability in static and dynamic applications.

©2024 Vinit Stainless All Rights Reserved.