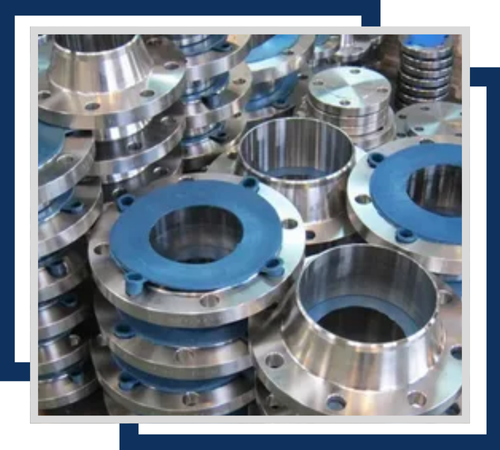

SS 316Ti flanges are stainless steel flanges with addition of titanium to provide resistance to high-temperature corrosion. The flanges are produced and offered by Vinit Stainless in Chennai, India, for performance under harsh service conditions. The titanium addition makes them suitable for continuous service in sensitization-prone environments. These flanges are designed to adhere to strict industrial specifications and are utilized extensively in chemical and thermal processing facilities. Vinit Stainless maintains uniform quality, size accuracy, and international standards, making SS 316Ti flanges a safe option for important piping and pressure applications.

SS 316Ti flanges contain 16–18% Chromium, 10–14% Nickel, 2–3% Molybdenum, and 0.5–0.7% Titanium, which enhances high-temperature stability. Mechanical properties consist of tensile strength of around 515 MPa, yield strength of 205 MPa, and superior elongation as well as toughness. Addition of titanium avoids precipitation of carbides during welding and thus maintains corrosion resistance. These flanges retain structural stability in high temperature conditions and are thus best suited for stress-loaded conditions. Their chemical and mechanical balance offers durability and corrosion shielding under a range of aggressive conditions.

| Specifications | ASTM A182 / ASME SA182 |

| Size | 1/8″ NB TO 48″ NB |

| Standards | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grades | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| ELEMENT | MIN | MAX |

|---|---|---|

| C | – | 0.08 |

| Si | – | 0.75 |

| Mn | – | 2 |

| P | – | 0.45 |

| S | – | 0.03 |

| Cr | 16 | 18 |

| Mo | 2 | 3 |

| N | – | 0.1 |

| Fe | Balance | |

| Ni | 10 | 14 |

| Ti | 5x%(C+N) | |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

These flanges are designed to slip over the pipe end and are typically used for moderate-pressure applications. They come in various sizes, usually from 1/2″ to 24″ in diameter. SS 316Ti offers excellent corrosion resistance, especially in marine and acidic environments.

Characterized by a long neck that helps in reducing stress concentrations, these flanges are welded to the pipe for a strong, reliable joint. Available in sizes from 1″ to 24″, they provide superior corrosion resistance due to their titanium-stabilized composition.

These flanges are used to seal the end of a piping system or vessel, blocking the flow of fluid. Sizes range from 1″ to 24″, and they provide excellent resistance to corrosion, making them suitable for harsh environments

Featuring internal threads for easy attachment to pipes with matching threads, these flanges are typically available from 1/2″ to 6″. Their titanium content enhances corrosion resistance, particularly in aggressive chemical environments

Designed for high-pressure systems, these flanges are inserted into a socket and welded in place. They come in sizes from 1″ to 24″ and offer robust corrosion resistance due to the 316Ti alloy’s resistance to oxidation and chloride stress.

These flanges are used with a loose backing flange and provide a smooth, corrosion-resistant surface for easy alignment and maintenance. They are available in sizes from 1″ to 24″ and are highly resistant to rust and corrosion, suitable for various industries.

SS 316Ti flanges are widely applied in high-temperature strength and corrosion-resistant industries. They are utilized in heat exchangers, chemical process equipment, marine equipment, power generation equipment, and exhaust manifolds. Due to their resistance to intergranular corrosion, they are best suited for welded structures used in corrosive environments. For pressure vessels and piping systems for refineries and offshore fields, these flanges provide reliable service throughout their lifespan. The titanium content stabilizes the material so that it won’t sensitize and degrade with time, which is extremely important in continuous operation applications. Their corrosion performance and strength make them a reliable choice for severe service conditions.

©2024 Vinit Stainless All Rights Reserved.