Premium-grade stainless steel 317 bars designed for extremely corrosive and high-stress industrial settings are available from Vinit Stainless, a well-known manufacturer and supplier with headquarters in Chennai, India. Compared to standard 304 and 316 grades, SS 317, an austenitic stainless steel that contains molybdenum, exhibits superior corrosion resistance, particularly in environments that are acidic and chloride-rich. Vinit Stainless uses sophisticated equipment and stringent quality control to produce these bars in order to satisfy both client and international standards. Our SS 317 bars, which come in a variety of sizes and finishes, are perfect for the paper, chemical, petrochemical, and marine industries where dependability and durability are crucial.

18–20% chromium, 11–15% nickel, and 3–4% molybdenum make up stainless steel 317 bars. Manganese, silicon, and up to 0.08% carbon are also added. The resistance to pitting and crevice corrosion is greatly increased by the high molybdenum content. SS 317 bars normally have a yield strength of about 205 MPa and a tensile strength of 515–760 MPa. The alloy offers outstanding formability, weldability, and ductility. It works effectively in harsh chemical and mechanical environments, providing stability and resistance to corrosion in high-temperature and reducing media such as phosphoric and sulphuric acids.

| Specifications | ASTM A 276 / SA 276 |

|---|---|

| Dimensions | ASTM, ASME |

| Range | 3.17 MM TO 350 MM DIA |

| Diameter | 25mm to 152mm |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wiremesh, Billet, Ingot, Forging Etc., |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Grade | C | Mn | Si | P | S | Cr | Ni | Mo | N |

| SS 317 | 0.08 max. | 2.00 max. | 1.00 max. | 0.045 max. | 0.03 max. | 18.0 – 20.0 | 11.0 – 14.0 | 3.0 – 4.0 | – |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | ||

| Rockwell B (HR B) max | Brinell (HB) max | |||||

| 317 | 620 MPa | 275 MPa | 45% | 85 | 193 | – |

Contact us to get a quick quote for your requirement.

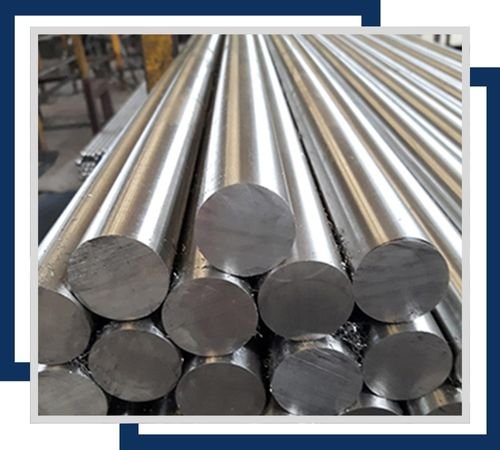

Corrosion-resistant Stainless Steel 317 Round Bars come in various diameters, typically from 6mm to 300mm. They are ideal for applications requiring high resistance to chloride corrosion, such as marine and chemical environments.

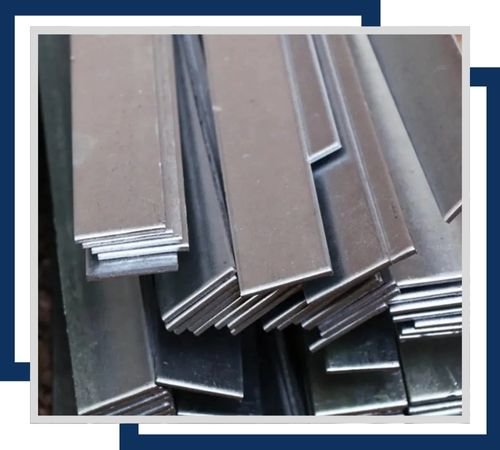

Stainless Steel 317 Flat Bars are available in widths ranging from 10mm to 300mm and thicknesses from 3mm to 50mm. These bars excel in resisting corrosion and are used in structural applications exposed to harsh chemicals.

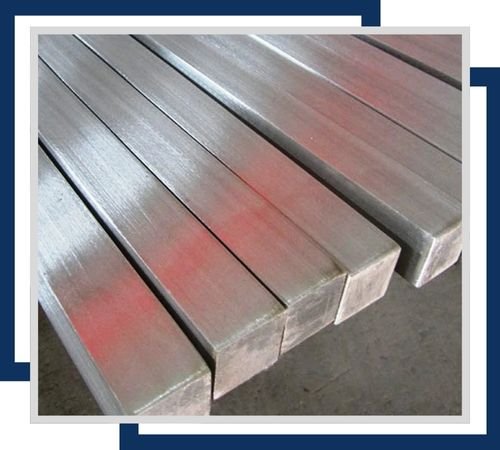

Stainless Steel 317 Square Bars, offered in sizes from 10mm to 100mm, provide excellent resistance to corrosion in aggressive environments. They are used in various structural and manufacturing applications requiring robust material properties.

Stainless Steel 317 Rectangular Bars come in dimensions like 20mm x 10mm to 150mm x 50mm. They are preferred for applications needing high strength and resistance to corrosive substances, such as heat exchangers.

Corrosion-resistant Stainless Steel 317 Hexagonal Bars, available in sizes from 10mm to 100mm across flats, offer excellent performance in corrosive environments. They are used in industries where both strength and corrosion resistance are critical.

Stainless Steel 317 T-Bars are typically available in sizes like 10mm x 10mm to 100mm x 100mm. These bars provide high resistance to corrosion and are used in structural supports and frameworks exposed to aggressive conditions.

Industries that need to withstand harsh chemicals, high pressure, and high temperatures frequently use stainless steel 317 bars. Equipment used in the food processing, textile dyeing, pulp and paper, and chemical processing industries are examples of common applications. These bars are perfect for piping systems, heat exchangers, tanks, and evaporators that are subjected to strong corrosive substances like phosphoric acid, sulphuric acid, and chlorides. They are also appropriate for pollution control systems and marine environments due to their exceptional resistance to oxidation and corrosion. Because of their mechanical strength and resistance to stress corrosion cracking, SS 317 bars are preferred in welded and fabricated structures.

©2024 Vinit Stainless All Rights Reserved.