Vinit Stainless, based in Chennai, India, is a prominent manufacturer and supplier of high-quality stainless steel products. Backed by a strong reputation for excellence and reliability, we offer a wide range of stainless steel solutions tailored for demanding industrial applications. Among our premium offerings is Stainless Steel 317L Tubing, known for its exceptional corrosion resistance, durability, and high performance in aggressive environments. With a commitment to precision engineering, timely delivery, and superior customer service, Vinit Stainless continues to be a trusted partner for industries across India seeking long-lasting and efficient stainless steel solutions.

A low-carbon version of 317 stainless steel, stainless steel 317L tubing is made especially to provide improved weldability and resistance to intergranular corrosion. With a maximum carbon content of 0.03%, its typical composition consists of 18–20% chromium, 13–15% nickel, and 3–4% molybdenum. In environments that are acidic and chloride-rich, these elements offer exceptional resistance to pitting and crevice corrosion. The tubing maintains mechanical integrity under both high-temperature and cryogenic conditions thanks to its tensile strength of 515–690 MPa, yield strength of 205 MPa, and elongation of 40%.

| ASTM A213 / ASME SA 213 | Standard Specification for SS TP 317L Seamless Superheater, Condenser, Hydraulic, Boiler and Heat-Exchanger Tubes |

| Shapes | ASME SA213 TP317L Round, Rectangular, Square, Hydraulic, Straight, “U” Shape, Coiled, Honed Tubes, Pan Cake Coils |

| Manufacturing Type | Seamless / ERW / Welded / Fabricated / CDW / CDS / DOM / CEW / 100% X Ray Welded |

| Delivery Condition | Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold Drawn, MF |

| Surface Finish | BA, 2B, No.4, No.1, No.3, No.8, 8K, HL, 2D, 1D, Mirror Polished, 180G, 320G, 400G Satin/ Hairline, 400G, 500G, 600G or 800G Mirror finish DIN 1.4438 Stainless Steel 317L Tubing or Custom Finish as per customer’s specification |

| Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXH, SCH XXS, SCH XS |

| Standard | SUS, JIS, AISI, ASTM, GB, DIN, EN |

| Relevant Standard | ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A554, ASTM A249, ASTM A269, ASTM A270, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3605, GB13296 |

| Value Added Services |

|

| SS 317L | Maximum |

|---|---|

| Ni | 11 – 15 |

| C | 0.035 Maximum |

| Mn | 2 Maximum |

| P | 0.040 Maximum |

| S | 0.03 Maximum |

| Si | 1 Maximum |

| Cr | 18 – 20 |

| Mo | 3 – 4 |

| N | – |

| Element | AISI 317L |

|---|---|

| Density | 8.0 g/cm3 |

| Melting Range | 1454 °C (2650 °F) |

| Tensile Stress | Psi – 75000 , MPa – 515 |

| Yield Stress (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| Hardness (Brinell) | – |

Contact us to get a quick quote for your requirement.

We offers thorough testing and certification of its stainless steel 317L tubing, ensuring the highest quality and performance. Each batch undergoes rigorous inspection, including mechanical testing, chemical analysis and pressure testing. Certifications are issued, proving compliance with international standards as well as good reliability and customer-specific requirements.

Stainless Steel 317L seamless tubing is a corrosion-resistant alloy ideal for chemical, pharmaceutical, and food processing industries, offering superior strength, weldability, and durability in harsh environments.

Stainless Steel 317L welded tubing is highly resistant to corrosion, ideal for chemical, pharmaceutical, and food processing industries, offering excellent weldability, strength, and durability in demanding environments.

Stainless Steel 317L heat exchanger tubes provide excellent resistance to corrosion and high temperatures, making them ideal for use in chemical, petrochemical, and power generation industries with superior heat transfer performance

Stainless Steel 317L instrumentation tubing offers high corrosion resistance and excellent durability, making it ideal for precise applications in chemical, petrochemical, and pharmaceutical industries, ensuring reliable performance in demanding environments.

Stainless Steel 317L boiler tubes are designed for high-temperature and corrosive environments, providing exceptional resistance to oxidation and scaling, making them ideal for industrial boilers and heat exchangers.

Stainless Steel 317L U-tubes offer high corrosion resistance and durability, ideal for heat exchangers and industrial applications requiring exceptional performance under harsh conditions and high temperatures.

Stainless Steel 317L condenser tubes provide excellent resistance to corrosion and high temperatures, making them perfect for use in heat exchangers and cooling systems in chemical and petrochemical industries.

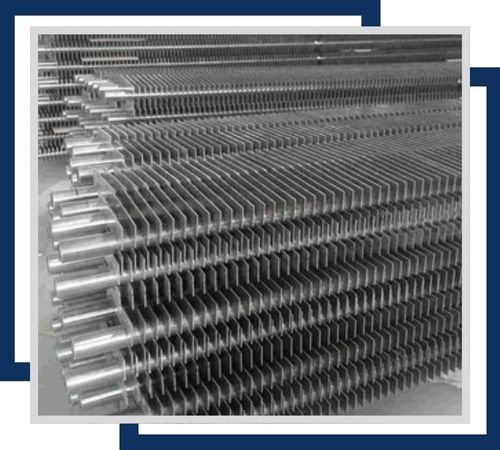

Stainless Steel 317L fin tubes enhance heat transfer efficiency with superior corrosion resistance, making them ideal for applications in heat exchangers, air coolers, and industrial processes requiring reliable performance.

Industries that demand high corrosion resistance, strength, and long-term durability frequently use stainless steel 317L tubing. Its low carbon content improves performance in petrochemical, pharmaceutical, and chemical processing applications while preventing sensitization. It is widely used in evaporators, condensers, reactors, and heat exchangers. It is also appropriate for power generation systems, food processing facilities, and marine environments. Critical systems functioning in corrosive and high-stress environments benefit greatly from its resistance to harsh chemicals and high temperatures, which guarantees longevity and low maintenance under harsh service conditions.

©2024 Vinit Stainless All Rights Reserved.