High-quality stainless steel 317L coils from Vinit Stainless, a well-known manufacturer and supplier in Chennai, India, are designed to perform exceptionally well in extremely corrosive conditions. Low-carbon, molybdenum-bearing austenitic stainless steel SS 317L is renowned for its exceptional resistance to chemical attack, especially in environments that are acidic and chloride-rich. At Vinit Stainless, we make sure every coil is manufactured precisely, in accordance with international standards, and utilising cutting-edge technology. For a wide range of industrial applications requiring strength, durability, and corrosion resistance, such as chemical processing, pulp and paper, pharmaceuticals, and marine applications, our 317L coils come in a variety of sizes and finishes.

In order to avoid sensitisation and intergranular corrosion, stainless steel 317L coils have a low carbon content (maximum 0.03%), 18–20% chromium, 11–15% nickel, and 3–4% molybdenum. This composition offers improved defence against chemical attack, pitting, and crevice corrosion. SS 317L coils have a yield strength of roughly 170 MPa and a tensile strength of 485–620 MPa. At elevated temperatures, the alloy retains exceptional ductility, weldability, and creep resistance. Because of its mechanical and chemical stability, it is perfect for harsh service environments, particularly those that frequently involve exposure to harsh chemicals and high temperatures.

| Standard | ASTM A240, ASME SA240 |

| Thickness | 0.1mm to 12 mm Thk |

| Coil Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm etc. |

| Coil Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm etc. |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sandblast, Brush, etching. |

| Finish | Hot rolled (HR), Cold rolled (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated), Galvanized etc. |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18 – 20 | 3 – 4 | 11 – 15 | 57.845 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Contact us to get a quick quote for your requirement.

SS 317L slitting coils are the stainless steel strips that possess an exceptional corrosion resistance property, strength, and durability. These coils are extremely suitable for various industrial applications. In general, these show marvelous performance and reliability.

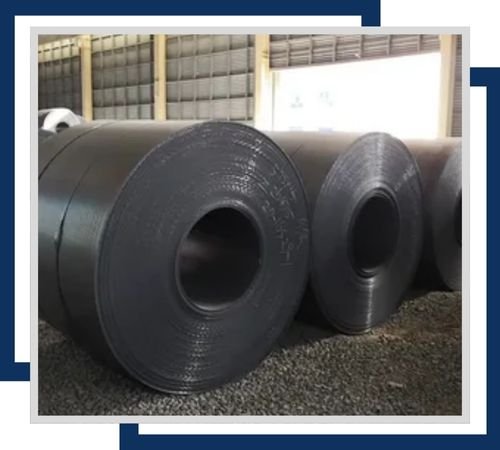

The SS 317L hot rolled coils are durable sheets of stainless steel possessing enhanced corrosion resistance and strength. These coils are used for extreme usage in various industrial applications.

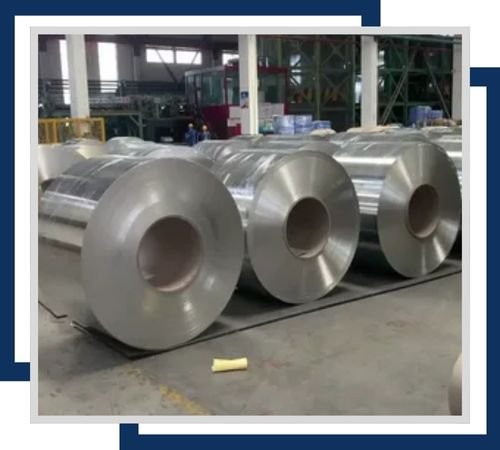

SS 317L cold rolled coils have a bright, smooth finish with excellent strength and corrosion resistance. They are suited for precision applications in industries where durability and good surface quality are required.

These Stainless Steel 317L HR slitting coils have a hot-rolled finish that makes them rugged, corrosion-resistant strips. This product offers the user with excellent strength and durability, perfect for demanding industrial and structural applications.

These Stainless Steel 317L slitting coils give excellent corrosion resistance and strength. The precision cut strips are perfectly suitable for manufacture and construction for providing durability and reliability in tough applications.

AISI 317L slitting coils are high-grade stainless steel strips that are corrosion resistant and strong. These are best for many industrial applications as they ensure durability and reliability in harsh environments and demanding conditions.

In industries where resistance to strong acids, chlorides, and high temperatures is essential, stainless steel 317L coils are widely used. Equipment used in pulp and paper mills, food processing systems, chemical processing facilities, and pharmaceutical manufacturing are examples of common applications. These coils are perfect for making scrubbers, heat exchangers, tanks, and pressure vessels for use in corrosive environments. Because of its low carbon content, SS 317L is especially well suited for welding and inhibits the precipitation of carbide during the fabrication process. They are also useful in pollution control and marine applications where long-term dependability and durability are crucial due to their exceptional resistance to phosphoric and sulphuric acids.

©2024 Vinit Stainless All Rights Reserved.