For applications needing exceptional resistance to high temperatures and intergranular corrosion, Vinit Stainless, a reputable manufacturer and supplier in Chennai, India, provides premium stainless steel 321 coils. Austenitic stainless steel stabilised with titanium, SS 321 was created especially for applications involving extended heat exposure. Vinit Stainless makes sure that our 321 coils are produced in accordance with international quality standards by utilising cutting-edge processes and premium materials. These coils are perfect for heat exchangers, furnace components, and exhaust systems in sectors like petrochemical, aerospace, and thermal processing because they come in a range of thicknesses, widths, and finishes.

In order to stabilise the alloy against carbide precipitation, stainless steel 321 coils usually have 17–19% chromium, 9–12% nickel, and titanium added in amounts at least five times the carbon content. After welding, this stabilisation enables the material to withstand intergranular corrosion. SS 321 has a yield strength of roughly 205 MPa and a tensile strength of 515–750 MPa. At high temperatures (up to 870°C), the alloy maintains good strength and ductility while providing exceptional resistance to oxidation. Because of its mechanical qualities, it is perfect for welded and high-temperature structural applications without sacrificing corrosion resistance.

| Specifications | ASTM A240, ASME SA240 |

| Standard | JIS, ASTM, AISI, GB, EN, DIN |

| Surface | 2B, BA, HL, No. 4, Mirror etc. |

| Finish | Cold rolled, Hot rolled |

| Thickness | 0.3mm–100mm |

| Size | 1000mm, 1219mm, 1250mm, 1500mm, 1524mm, 2000mm |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50 mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 321 | 515 | 205 | 40 | 95 | 217 |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

Contact us to get a quick quote for your requirement.

SS 321 slitting coils are stainless steel strips, processed through slitting, ideal for high-temperature applications due to their excellent resistance to corrosion and oxidation. Used in various industrial sectors

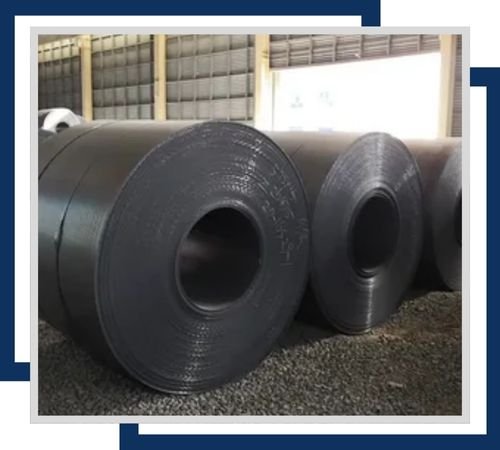

SS 321 hot-rolled coils are stainless steel sheets produced by heating and rolling, offering excellent resistance to corrosion and high temperatures, suitable for automotive, aerospace, and industrial applications,

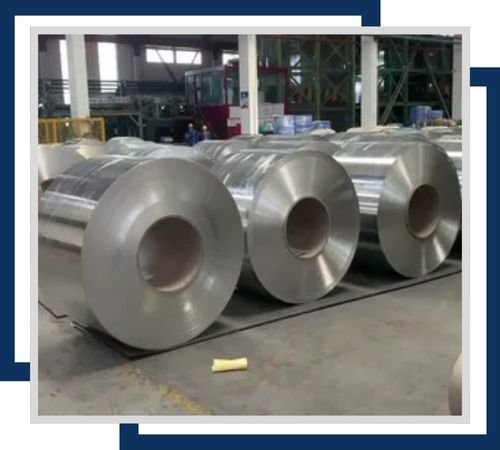

SS 321 cold-rolled coils are stainless steel sheets processed at room temperature, providing a smooth surface and precise dimensions, ideal for applications requiring excellent corrosion resistance and structural integrity.

Stainless Steel 321 HR slitting coils are hot-rolled, slit stainless steel strips, offering excellent heat and corrosion resistance. They are used in industries requiring high durability and precision.

Stainless Steel 321 slitting coils are precision-cut strips of heat-resistant stainless steel, ideal for applications requiring high corrosion resistance and strength, commonly used in aerospace, automotive, and industrial sectors.

AISI 321 slitting coils are stainless steel strips with excellent heat and corrosion resistance, processed by slitting. They’re suitable for applications in aerospace, automotive, and high-temperature environments.

321 Stainless Steel Applications needing high-temperature strength, weldability, and resistance to intergranular corrosion frequently use coils. SS 321 coils are used in the production of expansion joints, furnace linings, heat exchangers, exhaust systems and thermal shields in a variety of industries, including chemical processing, power generation, aerospace and marine engineering. Additionally, these coils are used in welded boiler tubes, pressure vessels, and jet engine parts. In settings where post-weld heat treatment is impractical, SS 321 coils are recommended for continuous service because of their exceptional stability and durability under thermal cycling, which guarantees performance and structural integrity over time.

©2024 Vinit Stainless All Rights Reserved.